Methods for arranging and supporting wall-expanded gas extraction drill sites

A technology for expanding sidewall gas and gas drainage, which is applied in the field of gas drainage and recovery roadway support, can solve the problems of affecting the efficiency of mining roadway excavation, large section span of recovery roadway, and large amount of manual construction, so as to facilitate support and roadway support. The effects of maintenance, reducing the strength of surrounding rock, and reducing the amount of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

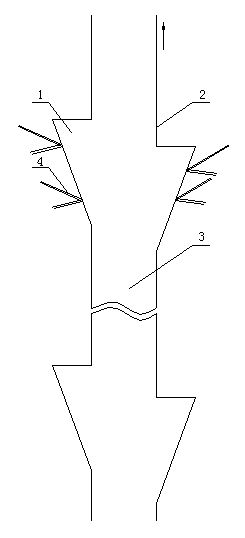

[0027] Such as figure 1 Shown, the arrangement of the present invention's extended side gas drainage drilling site:

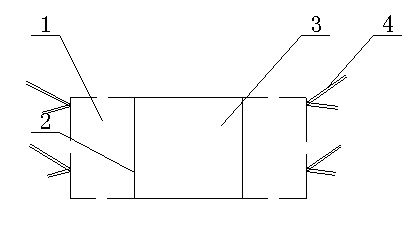

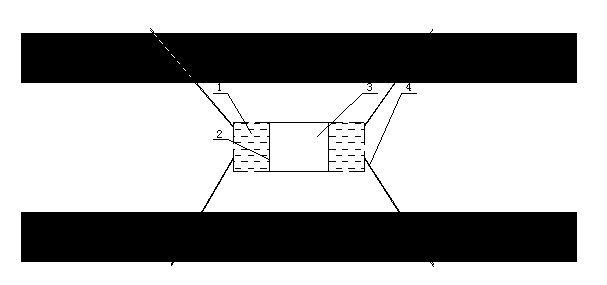

[0028]The layout of the expanded gas drainage drilling site of the present invention: firstly, according to the conventional technology, the mining roadway is excavated by the method of fully mechanized excavation or gun excavation, and then a plurality of wedge-shaped tunnels are staggered in front and rear in the two sides 2 of the mining roadway 3 Stepping drilling site 1, the distance between the front and rear staggered drilling site 1 is not less than 2m, the span of the stepping drilling site 1 gradually increases along the excavation direction of mining roadway 3, and its span is 0.5~3 m, and the excavation along mining roadway 3 The length in the direction is 3~8 m, and the distance between adjacent stepping drilling sites 1 is 60~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com