Method for extracting pressure relief gas by retained roadway drill site drilling

A drilling and drainage technology, applied in the field of coal mine gas drainage, can solve the problems of no working space, prone to collapse holes, and great influence on gas drainage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] The operation steps of the method for extracting pressure-relieving gas by the drilling method of retaining roadway drilling field of the present invention:

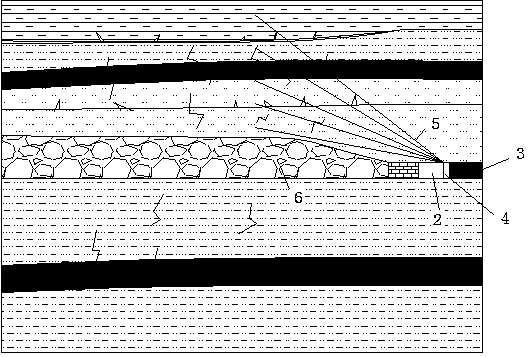

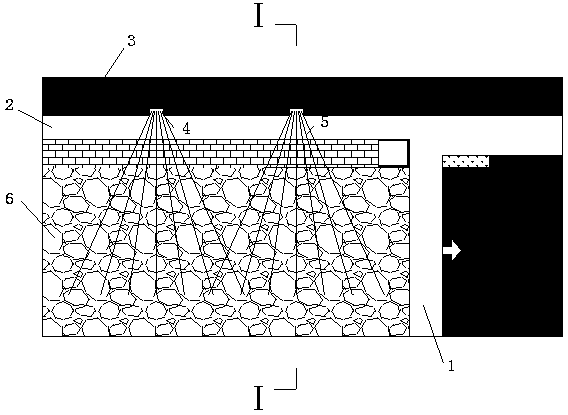

[0019] a. Multiple drill sites 4 are constructed at intervals on one side of the solid coal 3 in the entryway 2 at 20-50m behind the coal mining face 1, and the drill sites 4 are supported to provide work space for the construction of the drainage borehole 5 The distance between the plurality of drilling sites 4 of the interval construction is 50-100m, the span of the drilling site 4 is 2-3m, the length is 4-5m, and the height is equal to the roadway height;

[0020] b. Multiple gas drainage boreholes 5 are constructed on the roof of the goaf 6 in the drilling site 4. The final hole position of the drainage borehole 5 is 10-40m horizontally away from the entryway 2, and the normal distance from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Drilling depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com