Method for draining coal seam gas

A technology for coal seam gas and coal seam, which is applied in the field of coal mine pre-drainage of coal seam gas in the developed area or its adjacent area, can solve the problems of unfavorable gas extraction, large production investment, low methane concentration, etc., and achieves the improvement of gas efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

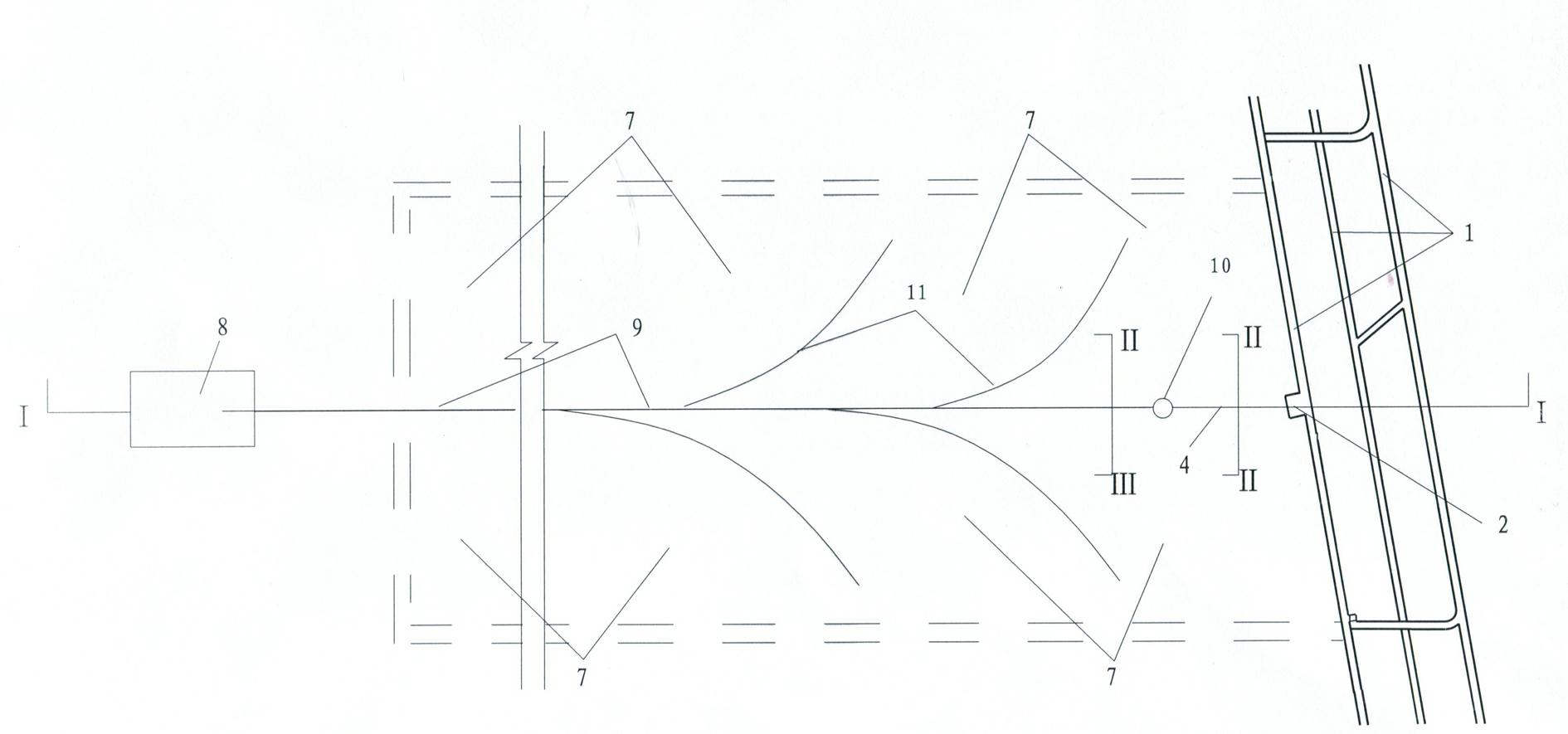

Embodiment 1

[0023] Such as figure 1 As shown, a method for extracting coal seam gas in this embodiment, it first opens up a butt hole drilling site 2 in the coal mine underground preparation roadway 1, and constructs a 30-50m methane drilling site from the butt hole drilling site to the target coal seam 3 In the butt hole 4 of the butt hole 4, a seamless steel casing 5 is inserted and cemented with high-grade cement 6; then, at the far end of the designed drainage area 7, a ground drilling field 8 is opened, and the butt hole is drilled downhole. The horizontal directional main branch hole 9 is drilled in the direction of the hole 4 along the construction of the target coal seam 3, and the horizontal directional main branch hole 9 is docked with the downhole docking hole 4 through the docking point 10; The orifice control valve is installed on the pipe head of the seam steel casing 5, and the control valve is connected with the coal mine underground gas drainage pipe network, and the coal...

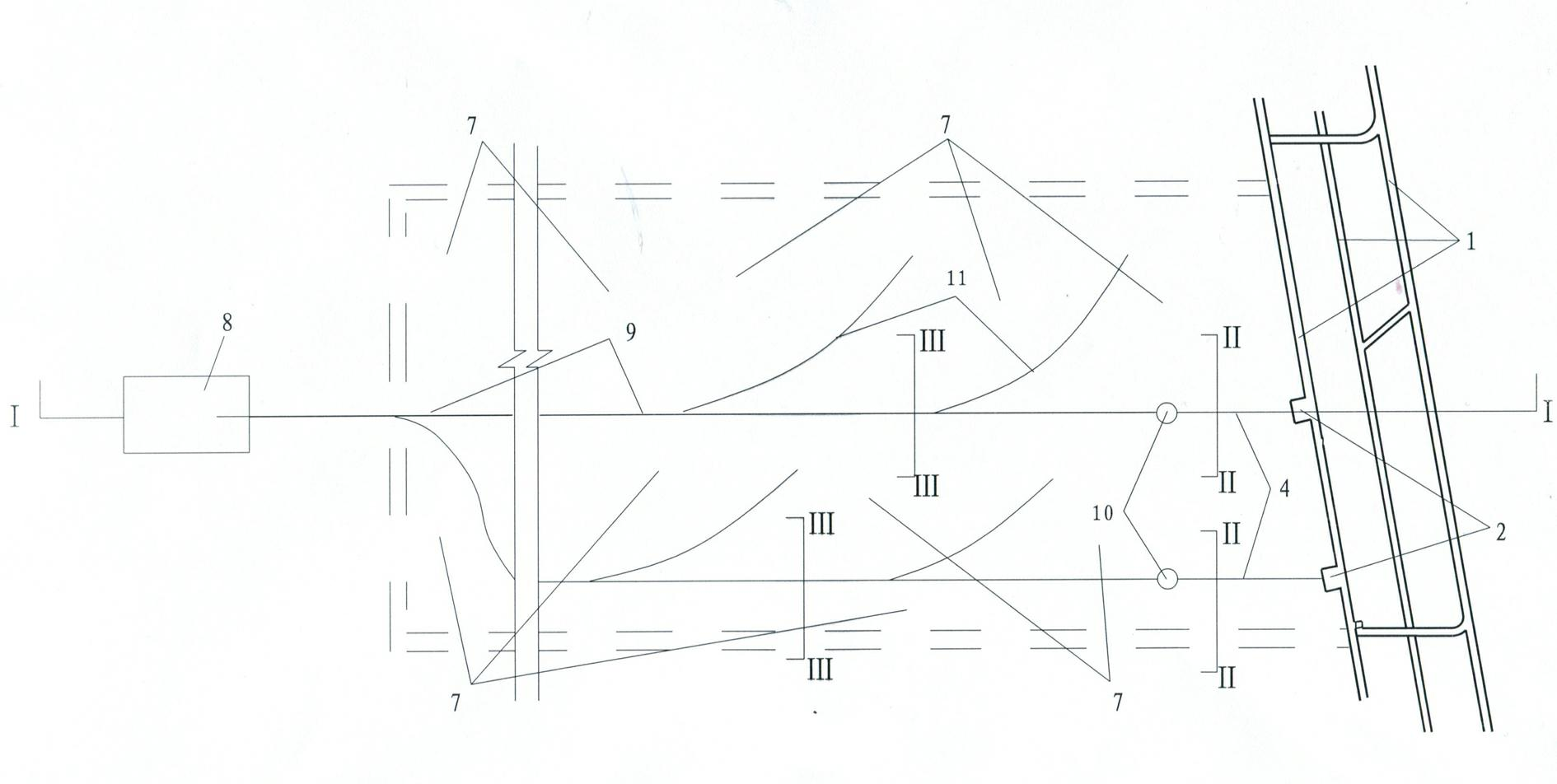

Embodiment 2

[0027] Such as figure 2 As shown, a method for extracting coal seam gas in this embodiment, first of all, two docking hole drilling sites 2 are opened in the preparation roadway 1 of the coal mine, and one drilling site is constructed from the two docking hole drilling sites to the target coal seam 3 respectively. 30-50m butt borehole 4, run seamless steel casing 5 into butt borehole 4 and fix the hole with high-grade cement 6; Two horizontal directional drilling horizontal directional main branch holes 9 are constructed along the target coal seam 3 in the direction of the downhole docking hole 4, and the horizontal directional main branch hole 9 is docked with the downhole docking hole 4 through the docking point 10; An orifice control valve is installed on the pipe heads of two seamless steel casings 5 that are drilled but connected, and the control valve is connected to the underground gas drainage pipe network of the coal mine, and the gas drainage pump is used for gas ...

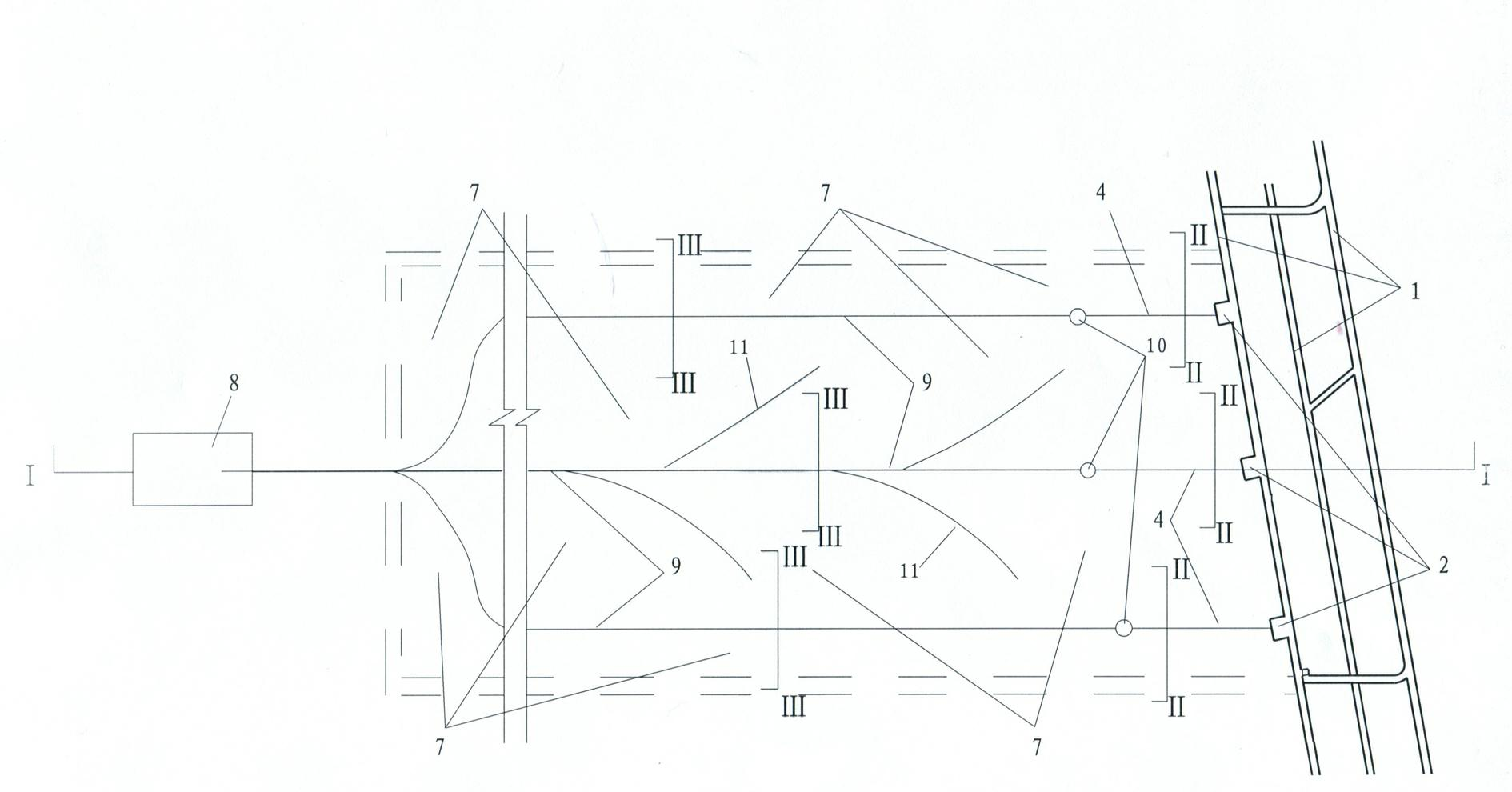

Embodiment 3

[0031] Such as image 3 As shown, a method for extracting coal seam gas in this embodiment, first of all, three docking hole drilling sites 2 are opened in the underground preparation roadway 1 of the coal mine, and one drilling site 2 is constructed from the three docking hole drilling sites to the target coal seam 3 respectively. 30-50m butt borehole 4, run seamless steel casing 5 into butt borehole 4 and fix the hole with high-grade cement 6; Three horizontal directional drilling horizontal directional main branch holes 9 are constructed along the target coal seam 3 in the direction of the downhole docking hole 4, and the horizontal directional main branch hole 9 is docked with the downhole butt hole 4 through the docking point 10; An orifice control valve is installed on the pipe heads of two seamless steel casings 5 that are drilled but connected, and the control valve is connected with the coal mine underground gas drainage pipe network, and the coal mine gas drainage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com