Integrated mining method for commonly mining coal and gas of high mine

A mining method and gas drainage technology, which is applied in the fields of gas discharge, mining equipment, earthwork drilling, etc., and can solve problems such as low permeability, difficult coal seam gas drainage, softness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

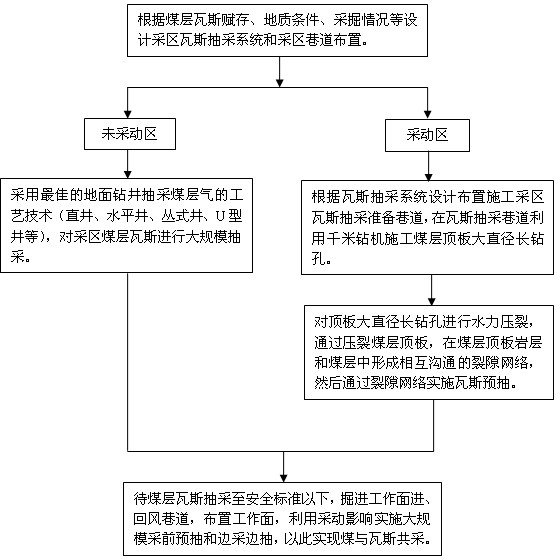

Method used

Image

Examples

Embodiment 1

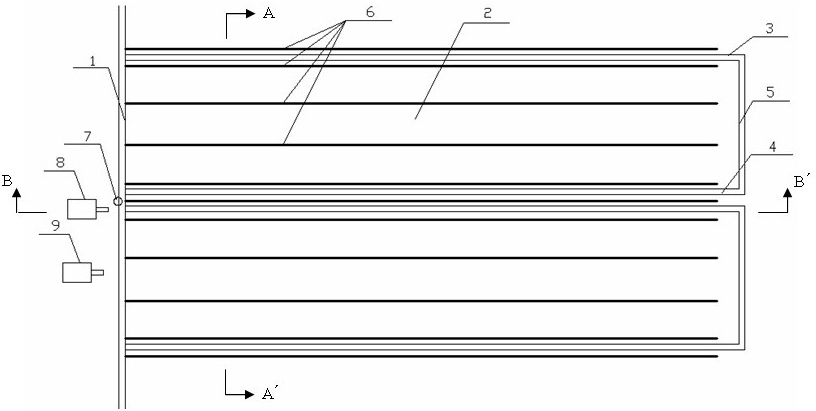

[0026] Such as figure 2 , 3 , Shown in 4, a mining method that implements coal and gas co-mining integration in a single, soft, low-permeability coal seam.

[0027] There is such a mining area: there are several working faces 2 in the mining area, the working face is 800m long in direction and 180m long in inclination. The thickness of the coal seam is 6m, and it is an outburst coal seam, which has the characteristics of soft coal quality, poor permeability, high gas content and high pressure in the coal seam. Severe coal seam gas outburst disasters and difficulties in roadway excavation have plagued mine production. In view of these problems, before the layout of the mining area, the gas drainage system is designed, and the coal seam gas is pre-drained by using the long hole 6 on the roof to eliminate outbursts in the area, cover the roadway excavation of the working face, and ensure the safety of mining at the working face.

[0028] The specific implementation steps are ...

Embodiment 2

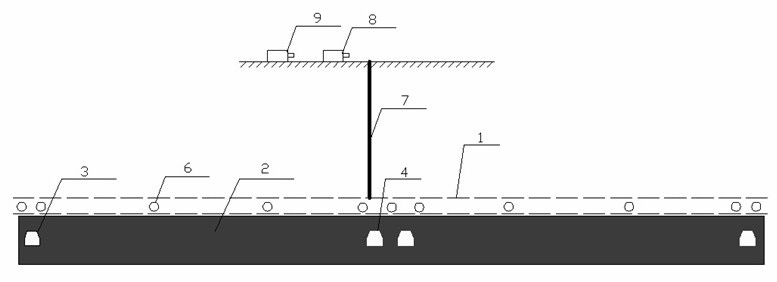

[0035] Such as Figure 5 , 6 , 7, in a single, soft, low-permeability coal seam, use the existing roadway in the mining area to implement the integrated mining method of coal and gas mining.

[0036] There is such a mining area: there are several working faces 2 in the mining area, the working face is 800m long in direction and 180m long in inclination. The thickness of the coal seam is 6m, and it is an outburst coal seam, which has the characteristics of soft coal quality, poor permeability, high gas content and high pressure in the coal seam. Severe coal seam gas outburst disasters and difficulties in roadway excavation have plagued mine production. There is already a working face in the mining area that goes to the roof roadway 7, and the long drilling hole 8 on the roof roadway 7 can be drilled on the working face inclined to the roof, and the long drilling hole 6 on the working face of the upper (lower) roadway in the mining area is moved to the roof to cover the roadwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com