Open hollow steel section-thermal insulation core material-thin panel composite energy-saving external wall panel

A technology of thin-walled steel and thin panels, applied in insulation, walls, building components, etc., can solve problems such as self-heaviness and inability to be reused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

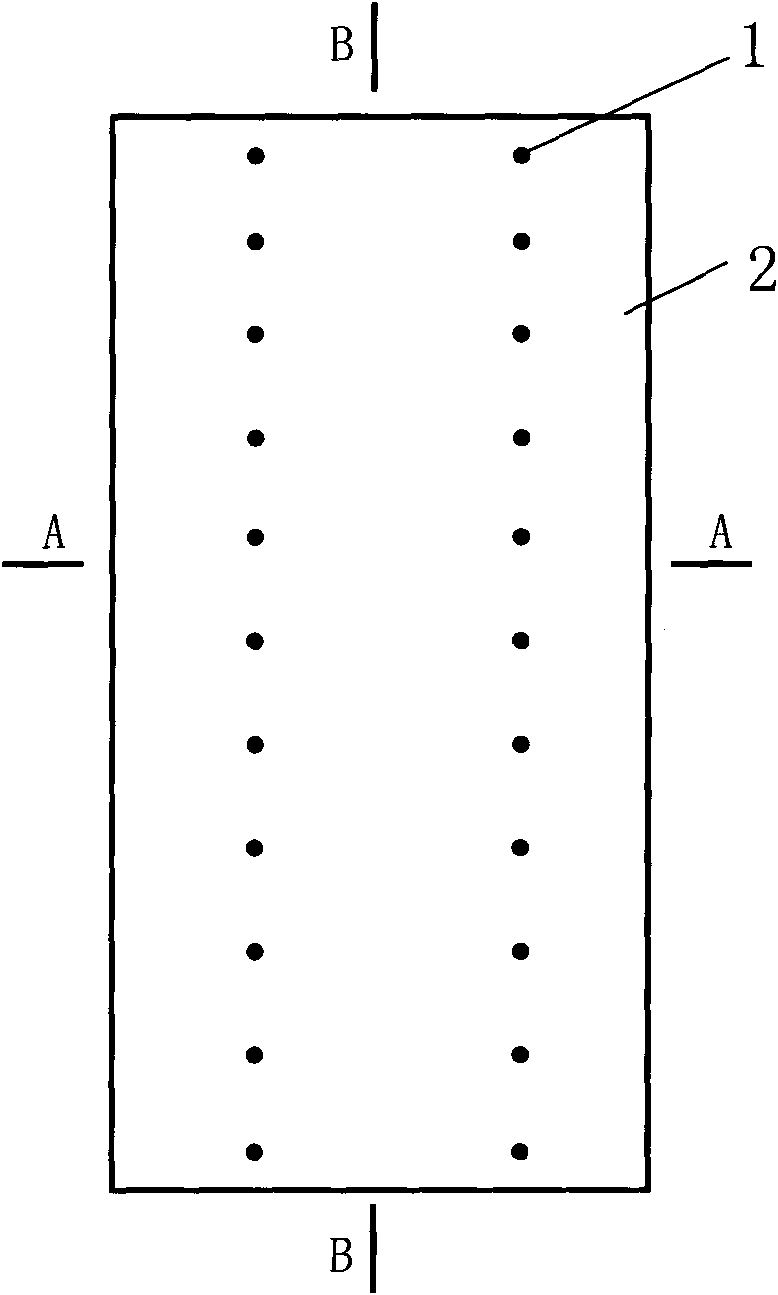

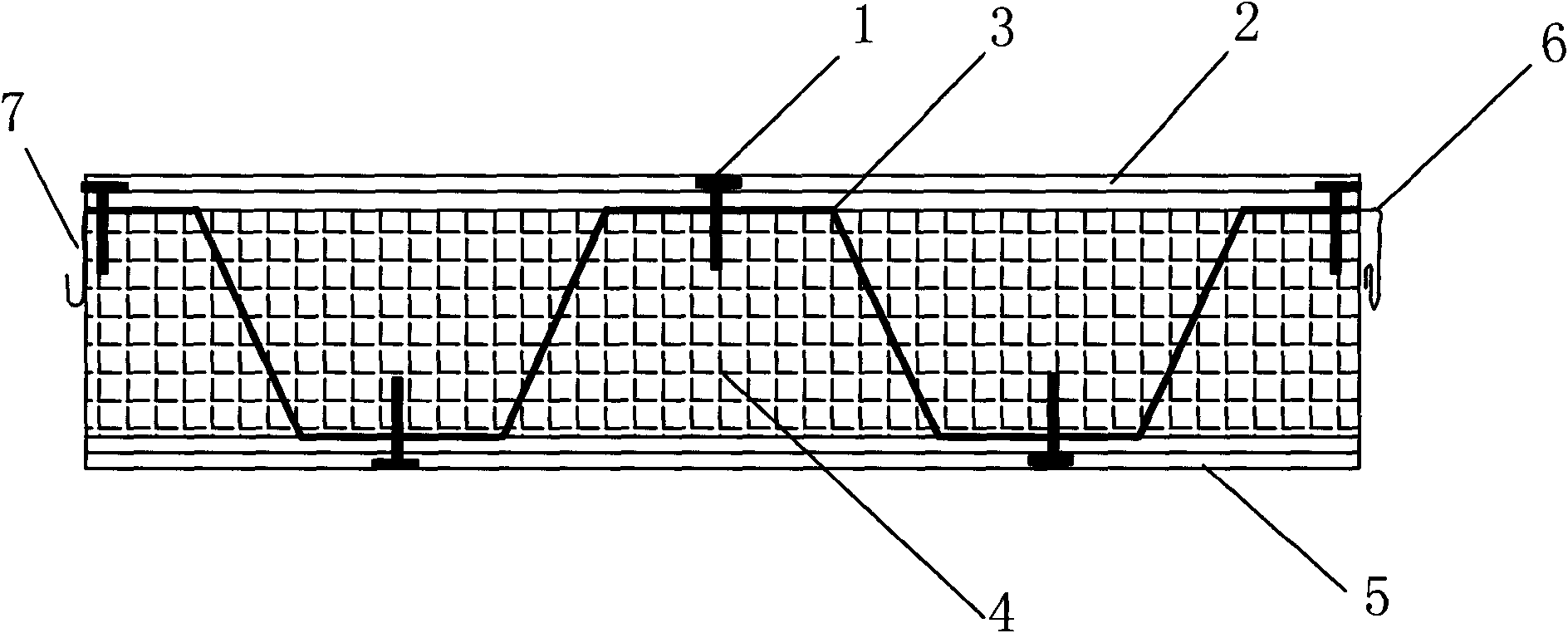

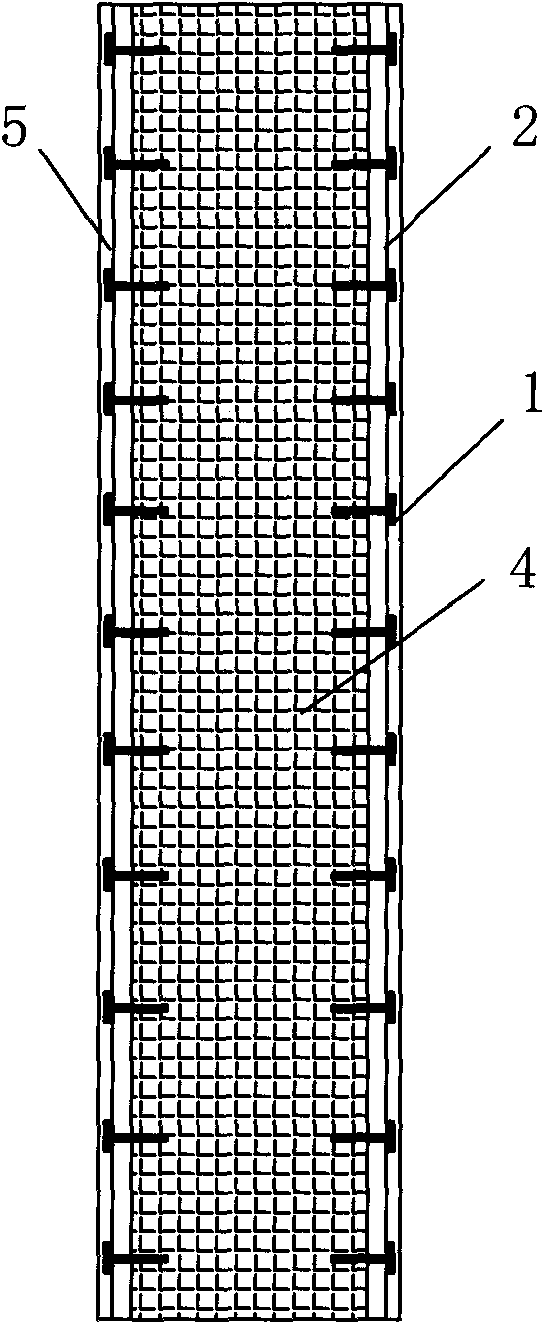

[0030] Such as figure 1 , figure 2 As shown, the wallboard load-bearing member of the composite energy-saving exterior wallboard of the present invention is composed of an open thin-walled steel plate 3 and two side panels. The two side panels include an outer panel 2 and an inner panel 5. The open steel plates are connected together, one end of the fastening connector 1 vertically penetrates the surface of the outer panel 2 , and the other end is flush with the upper surface of the outer panel 2 . In order to fully exert the connection function of the fastening connectors 1 , the fastening connectors 1 need to be evenly distributed on the surface of the outer panel 2 . The thermal insulation core material 4 is filled in the closed space formed by the plate ribs of the open steel plate 3 and the outer panel 2 and the inner panel 5, without occupying additional building space. The sub button 6 and the female button 7 form a female button. During construction and installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com