Novel automobile high-pressure-resistant oil tank isolation valve

A technology of isolation valve and high pressure resistance, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as polluting the environment, and achieve the effect of protecting the environment, reducing hydrocarbon emissions, and having a compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

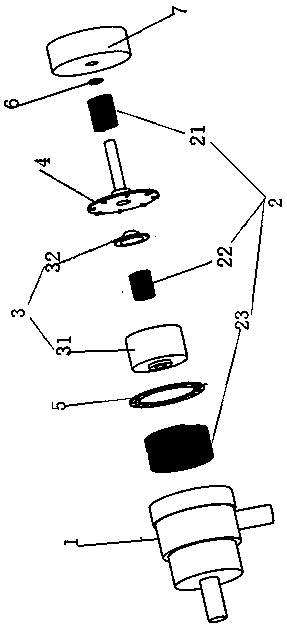

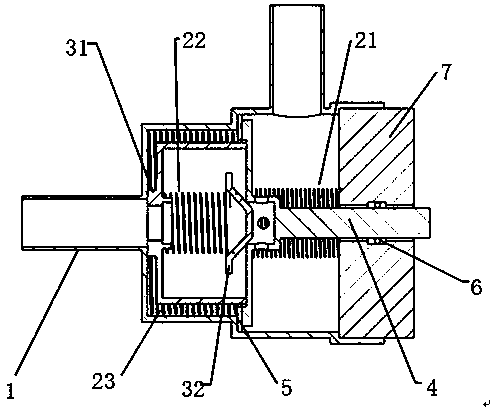

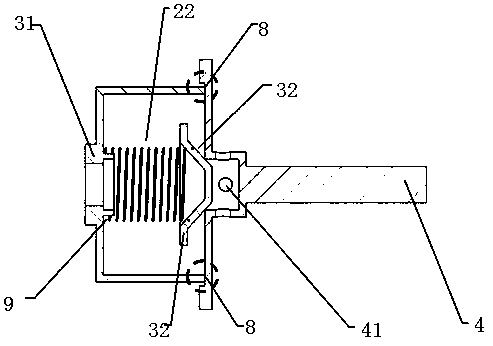

[0020] Example 1: see figure 1 , a new type of high-pressure resistant fuel tank isolation valve for automobiles, the fuel tank isolation valve includes an isolation valve body 1, a spring assembly 2, a valve core assembly 3, a support rod 4, a restrictor ring 5, a sealing ring 6 and a solenoid valve 7, the The spring assembly, spool assembly, current limiting ring, support rod, and sealing ring are all arranged in the isolation valve body, and the solenoid valve is arranged at the end of the isolation valve body. In this solution, the spring assembly includes the first spring 21, the second Two springs 22 and a third spring 23, the first spring is arranged on the support rod, the second spring is arranged between the support rod and the first sealing valve core 31, and the third spring is arranged in the isolation valve body , the spool assembly includes a first sealing spool 31 and a second sealing spool 32, the first sealing spool and the support rod are fixed together by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com