A kind of decorative board and its production process

A production process and technology for decorative panels, which are applied in decorative arts, processes for producing decorative surface effects, etc., can solve the problems of easy fading of the surface color of decorative panels, unapplied decorative panels, and easy falling off of decorative objects. Value, avoid color fading, eliminate the weathering effect of natural conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

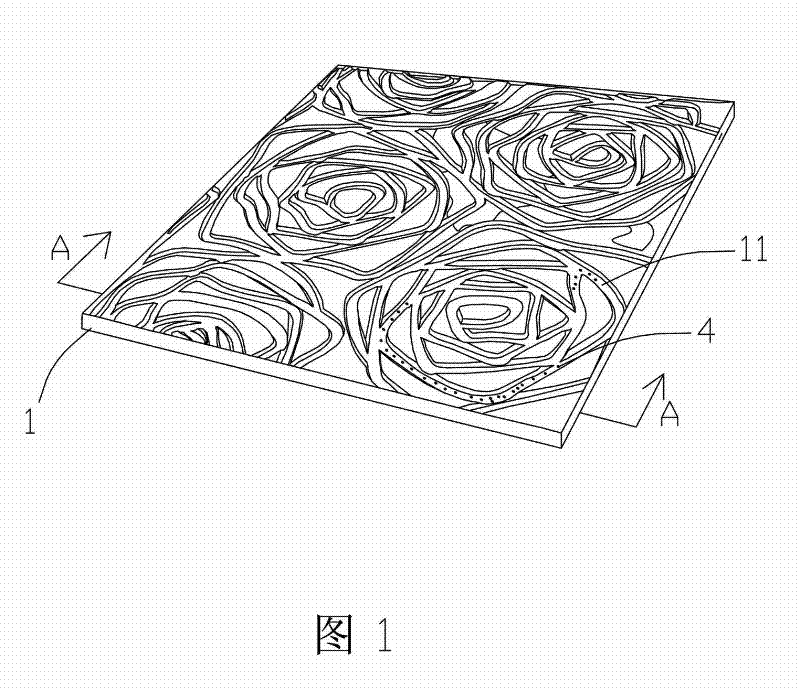

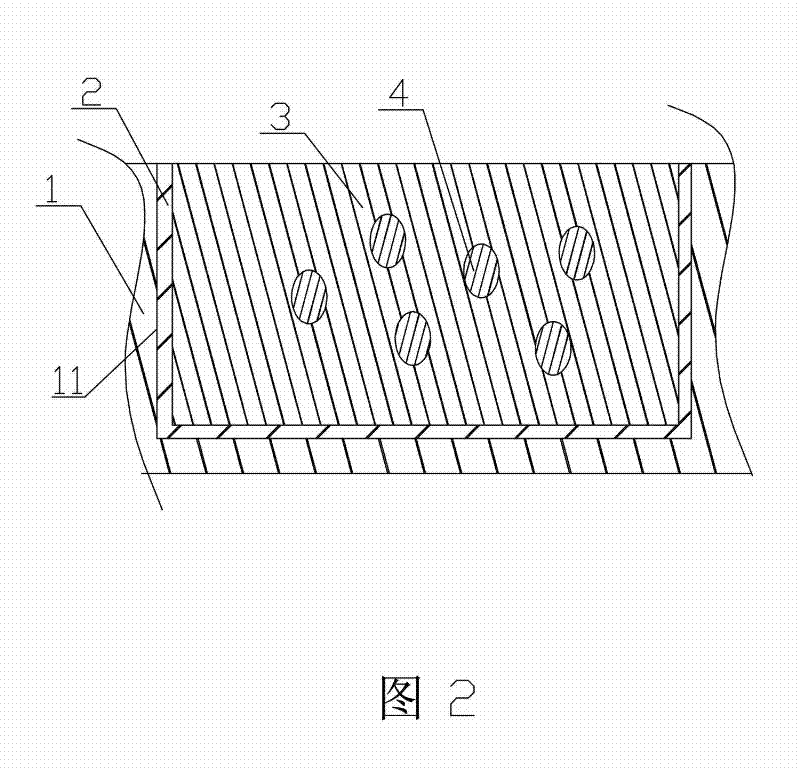

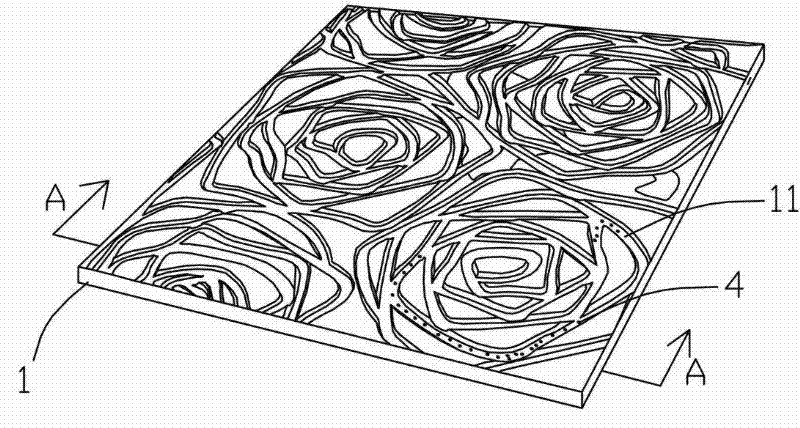

[0028] refer to figure 1 , figure 2 . A decorative board, comprising a decorative board body 1, a recessed texture 11 carved and formed by a numerical control engraving machine on the decorative board body 1, a patterned decorative layer 2 formed by spraying by a numerically controlled inkjet printer is arranged in the recessed texture 11, the recessed texture 11 The interior is filled with semi-precious stone decorations 4 and the resin glue layer 3 covering the semi-precious stone decorations 4 and the pattern decoration layer 2 .

[0029] The above-mentioned decorative board body 1 can be stone, ceramic tile, glass or wood board; the above-mentioned semi-precious stone decoration 4 is gold and silver powder, rhinestone or shell.

[0030] A production process of a decorative panel, comprising the following steps:

[0031] a. Input the data file containing the design pattern into the CNC engraving machine, the CNC engraving machine will automatically recognize it, and eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com