Perforation big head slip casting constant resistant anchor rod

A technology of bolting and grouting, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of failure of anchoring rock mass failure, reducing the strength of combined arches, increasing the anchoring area, etc., to achieve gas isolation, Prevents weathering and improves overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

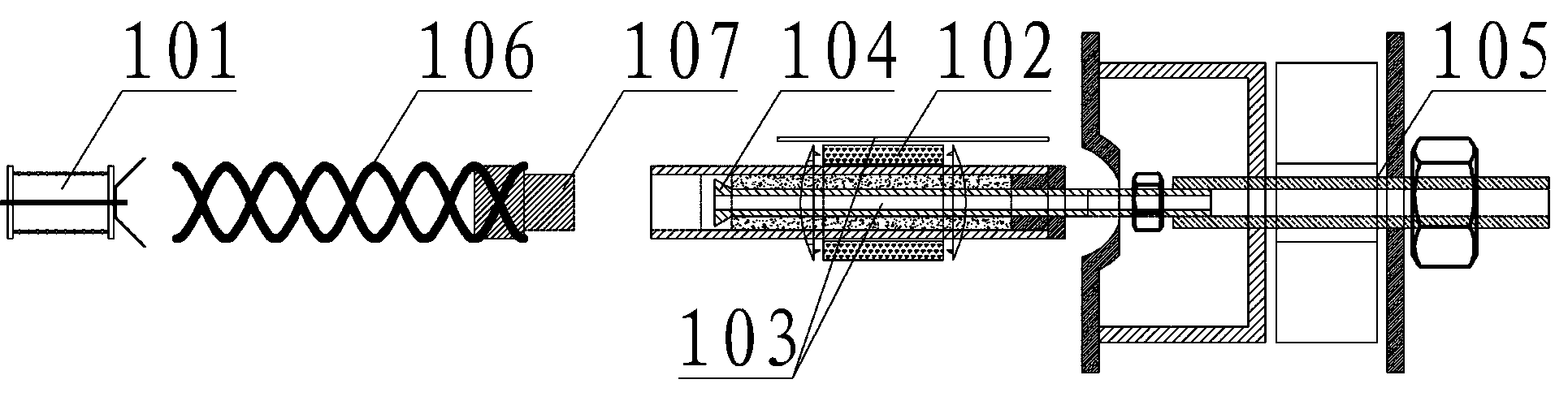

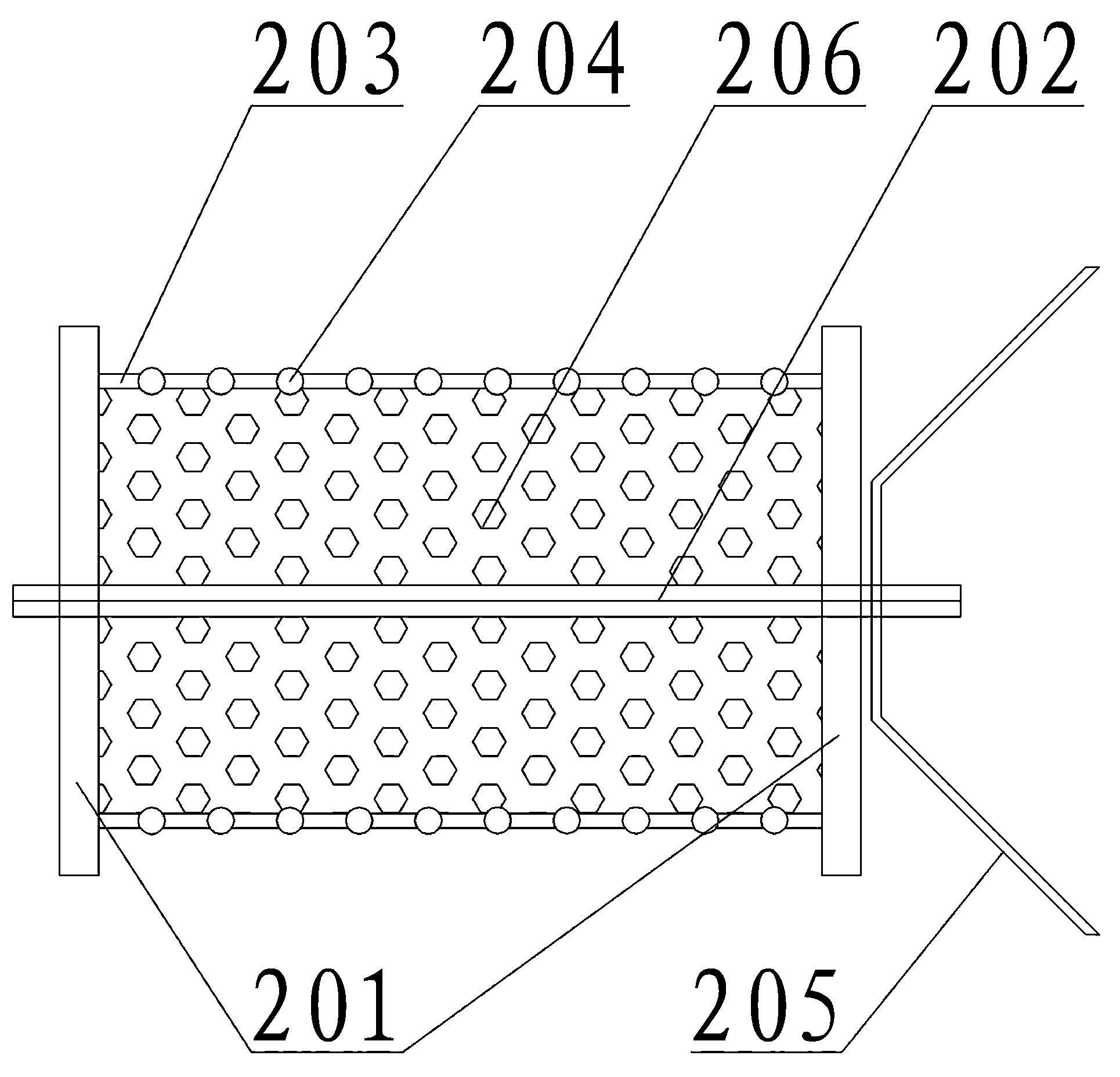

[0054] The perforated large-head grouting constant resistance anchor bolt forms a perforation crack at the end of the anchor bolt through the blasting perforation device 101, and then uses the O-shaped sealing drug roll device 102 to perform high-strength cracking at any reasonable position on the end, middle or tail of the anchor bolt. Anchor and seal, and then use the reserved high-pressure grouting device 103 to high-pressure grout in the broken coal rock mass (soft rock) at the end to form a large-headed anchor bolt, so that the original small contact area of the conical funnel stress structure 601 becomes a large-end The stress-bearing structure 602 of the platform with a large area at the head increases the thickness of the combined arch to improve the overall strength of the support (such as Figure 6 shown). The blasting and perforating device 101, the O-shaped sealing drug coil device 102 and the high-pressure grouting device 103 can be used in conjunction with ordina...

Embodiment approach 2

[0056] The lengthening detection device 105 of the perforating large head grouting constant resistance anchor rod is connected to the thread at the end of the anchor (cable) rod or the threaded anchor cable pressure flap through the lengthening connecting rod 502. 505 is set on the upper cover of the extended connecting rod, and the baffle plate 503 is tightened to detect the force situation. After the nut 504 on the extended connecting rod 502 is removed during the recovery process, the original anchor nut locks the anchor rod (the original anchor cable pressure flap lock Tighten the anchor cable), to prevent the failure of the anchor rod during the recovery process of the detection instrument 505, the excessive force on the anchor rod, the nut popping up and hurting people, and the detection instrument 505 being damaged and unable to be replaced. At the same time, the extended detection device 105 can be used with ordinary anchor (cable) rod The use achieves the effects of sa...

Embodiment approach 3

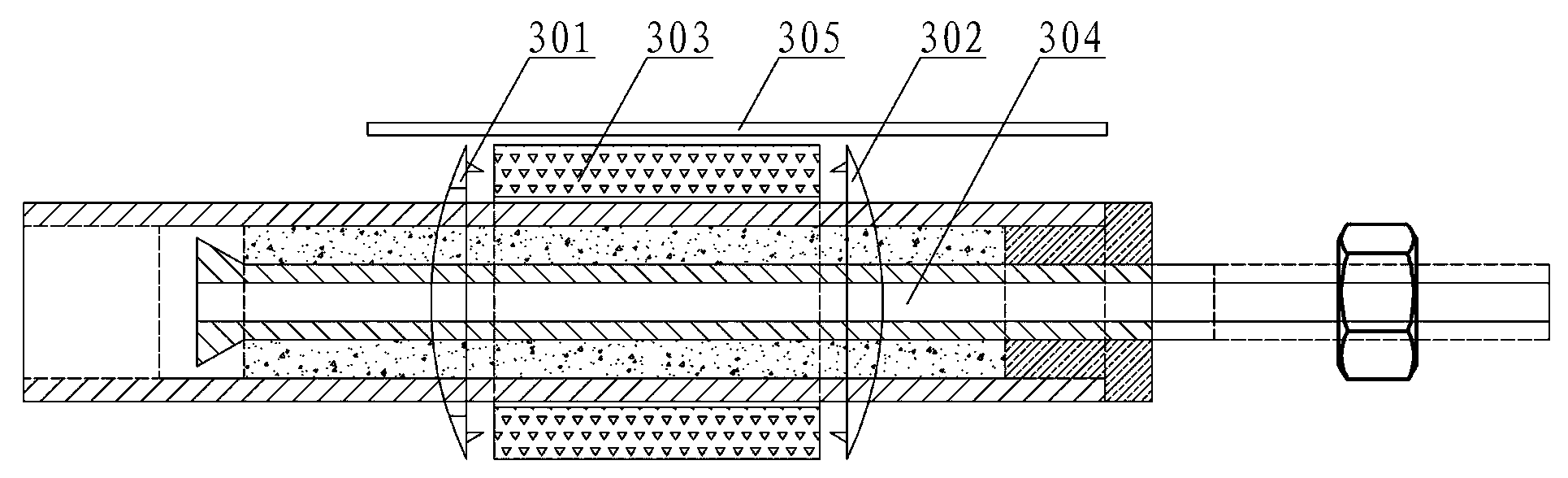

[0058] The constant resistance deformation device 104 of the perforated large head grouting constant resistance bolt is anchored on the bedrock through the outer casing 401, and the tail of the wedge head rod 403 is supported by a metal mesh, a tray and a nut to form an anchor mesh. When impacted, the O-shaped The resin deformation sleeve 402 deforms under force and constant resistance, which can effectively buffer the impact force and ensure the integrity of the support after buffer deformation and the constant resistance of the support strength. At the same time, the end of the perforated large-head grouting constant-resistance anchor rod is a threaded anchor cable connection structure 107 to form an extension anchor cable device 106. An extension anchor cable can be installed to form a constant resistance deformation anchor cable to improve the anchorage range of the anchor rod and the overall strength of the support. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com