Combined ecological slope protection method for rocky high slope

An ecological slope protection and combined technology, applied in the field of geotechnical engineering, can solve problems such as cumbersome procedures, high cost, and poor results, and achieve the effects of enhancing integrity and stability, slowing down physical weathering, and strengthening fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

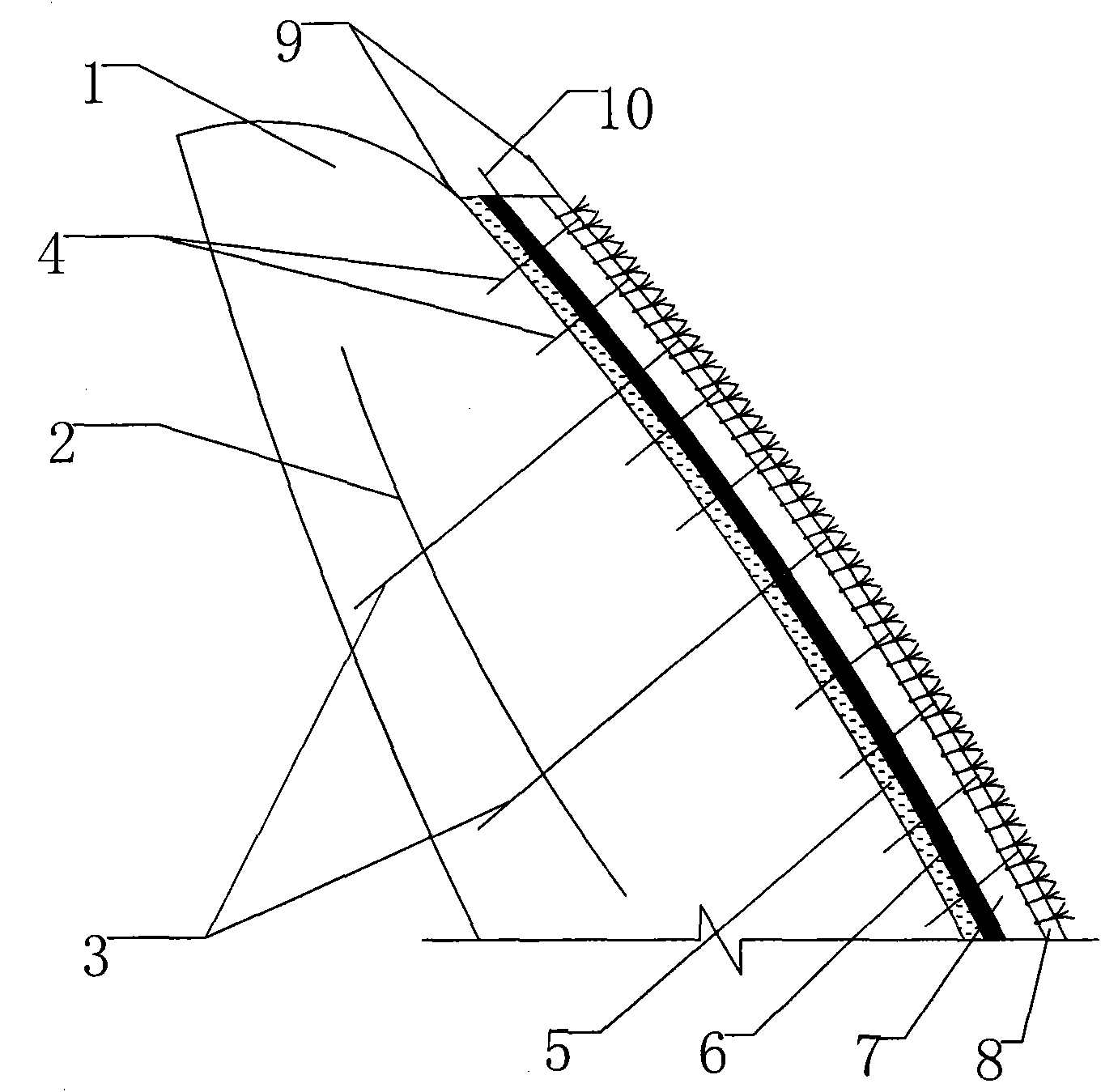

[0033] A high slope rock mass 1 has deep fractures 2 on it. Through the analysis and calculation of the slope stability by limit equilibrium method and numerical analysis method, it is found that 45×100 deep prestressed anchor cables are needed to fix the slope, and the distance between the rods is 2m, anchor cable length 27m, diameter 80mm; shallow fixed anchor rods 360×800, rod spacing 0.95m, anchor rod length 2m, diameter 25mm.

[0034] Set slope protection composite layer

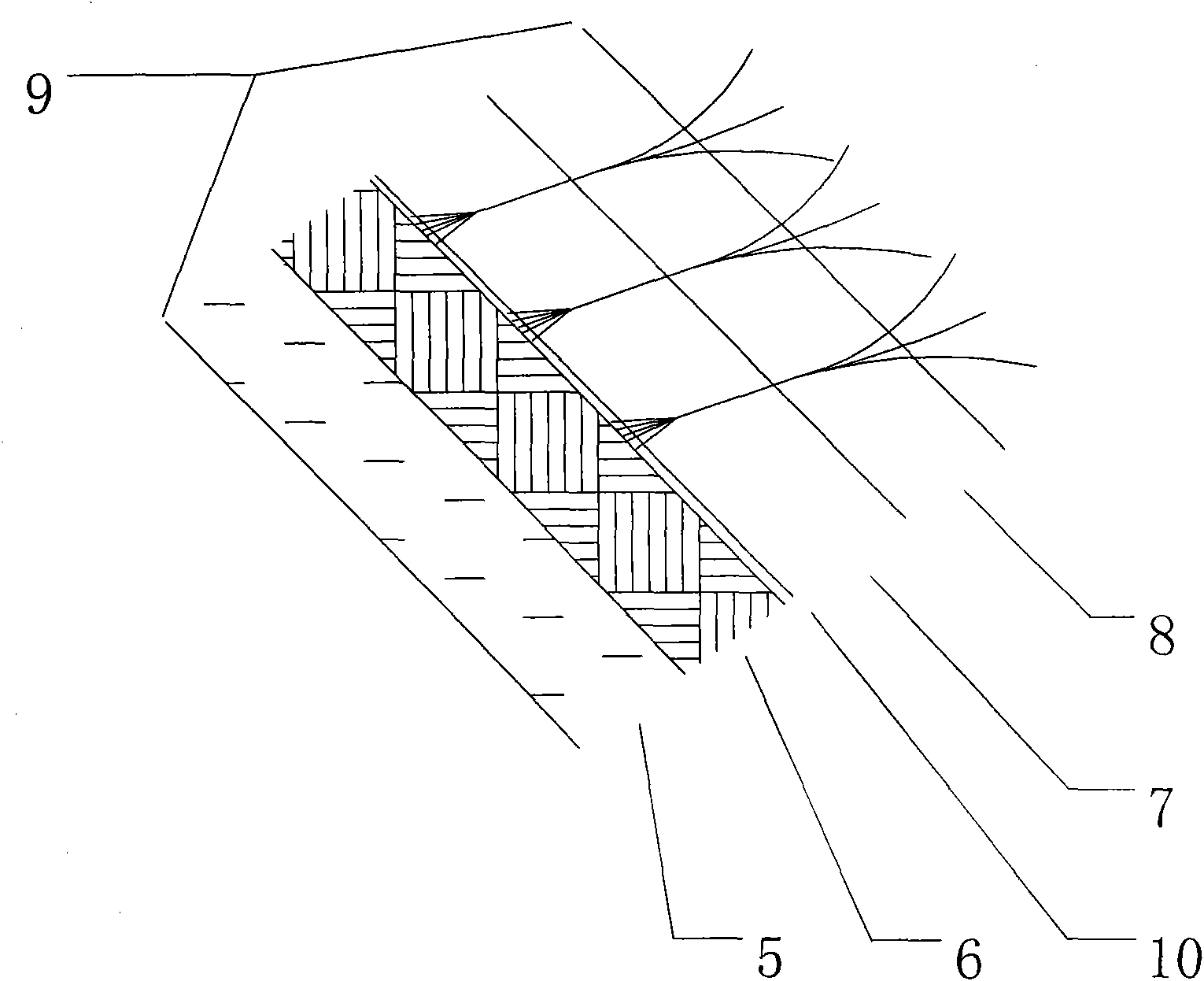

[0035] a. First set up steel wire mesh 9 in the lower layer, the mesh size is 3cm×3cm;

[0036] b. Set the anti-temperature change layer 5, and the thickness of the glass fiber felt is 3.5cm;

[0037] c. The waterproof layer 6 is set, and the thickness of the composite waterproof membrane is 2.8cm;

[0038] d. Set the stabilization layer 10, the mesh size of polymer net and nylon net is 5cm×5cm;

[0039] e. Set the nutrient matrix layer 7, the materials mainly include sandy loam, sawdust, chaff, stra...

Embodiment 2

[0046] The rock mass 1 of a high slope is relatively complete and has no deep cracks. After stability analysis, it is concluded that the slope does not need deep prestressed anchor cables, and only shallow anchors can be fixed to reinforce shallow micro cracks. The number of rods is 720×640, the distance between the rods is 0.95m, the length of the anchor rod is 1m, and the diameter is 25mm.

[0047] Set slope protection composite layer

[0048] a. First set up steel wire mesh 9 in the lower layer, the mesh size is 3cm×3cm;

[0049] b. Set the anti-temperature change layer 5, and the thickness of the glass fiber felt is 3.5cm;

[0050] c. The waterproof layer 6 is set, and the thickness of the composite waterproof membrane is 2.8cm;

[0051] d. Set the stabilization layer 10, the mesh size of polymer net and nylon net is 5cm×5cm;

[0052] e. The nutrient substrate layer 7 is set, and the materials mainly include sandy loam, sawdust, chaff, straw, compound fertilizer, etc.; ...

Embodiment 3

[0058] Rock sampling was carried out in a mountainous area in Jiangsu. The rock quality of the sample was sulfide ore. It was cut into two cubes of the same size (20*20*20cm), and a comparative test was carried out in the laboratory. The surface of sample 1 is covered with a simplified combined cushion, and sample 2 is bare rock. The temperature change and dripping tests are carried out on the two sample rock masses to simulate physical weathering and chemical weathering under extreme conditions.

[0059] The test steps are as follows:

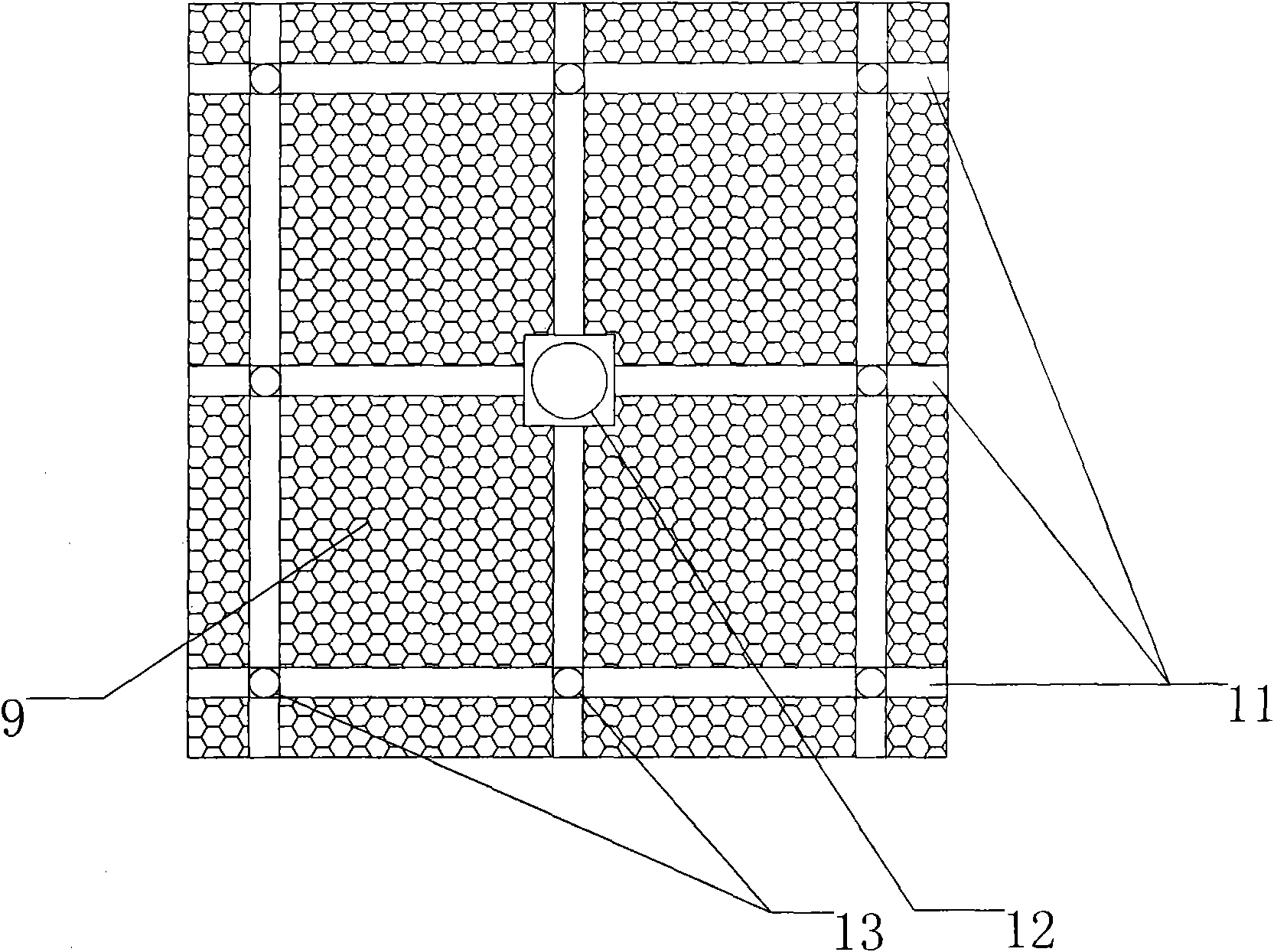

[0060] 1. Set up a simplified composite cushion for this test and cover it on the surface of sample 1. First, set the temperature-resistant layer 5, and the thickness of the glass fiber cotton felt is 1cm; set the waterproof layer 6, and the thickness of the composite waterproof membrane is 0.8cm; finally, use the bead 11 to press and form the whole;

[0061] 2. Temperature change test. Put two sample rock masses in a temperature-controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com