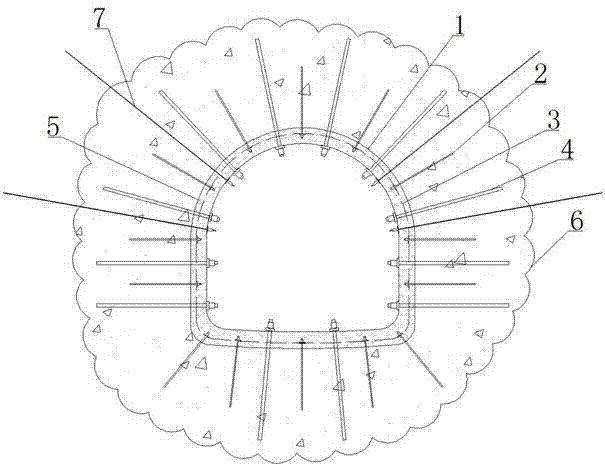

Supporting and reinforcing structure of coal mine tunnel and construction technology thereof

A technology for coal mine roadway and construction technology, applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as only 0.05-0.1MPa, inability to adapt to the law of surrounding rock deformation, and unmatched construction of reserved deformation layers, to prevent Weathering, ease of implementation and promotion, and the effect of expanding the effective carrying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

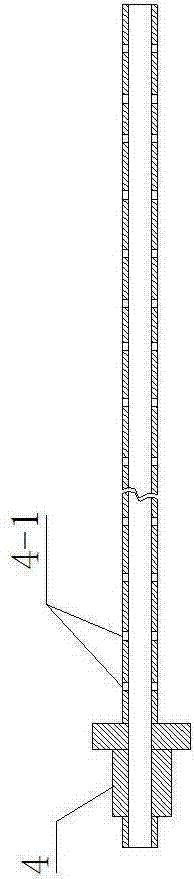

Method used

Image

Examples

specific Embodiment 1

[0046] Application of the present invention in Minmetals of Pingdingshan Coal Industry Group:

[0047] 1. Construction brief introduction: Pingdingshan Coal Industry Group Minmetals Minmetals Jisan lower extended mining area has a total of five downhills, namely, the lower part of the belt dark inclined shaft, the track downhill, the belt downhill, the east wing return wind down the mountain, and the west wing return wind down the mountain bottom The deformation is serious and the support is in disrepair. Especially for the track extending down the mountain and the depot, the average lane repair cycle is one year, and the serious section cannot meet the needs of safe transportation in less than one year.

[0048] The main factors causing the damage of the track downhill in the No. 3 Mining Area of Pingdingshan Coal Industry Group Mining Co., Ltd. are as follows:

[0049] (1) The surrounding rock of the roadway itself is relatively weak, and the roadway is arranged in ...

specific Embodiment 2

[0115] Application of the present invention in the eleventh mine of Pingdingshan Coal Industry Group:

[0116] 1. Project introduction: Since 2008, the 11th Mine of Pingdingshan Coal Industry Group has suffered serious convergence and deformation of the roadway. 2.5 meters, the actual width is 3.2 meters to 3.4 meters, and the outstanding performance of the roadway bottom drum is particularly serious; it has very prominently restricted the return air volume of the total return airway in the mining area, affecting safe production. In particular, we are deeply aware of the unequal horizontal stress in this area, which makes the approach of the upper side several times that of the lower side.

[0117] 2. The overall requirements for the support system to be established according to the site conditions:

[0118] a. Increase the intensity of replacing the bottom plate, and at the same time excavate the pressure relief groove at the bottom corner, increase the excavation of...

specific Embodiment 3

[0129] Application of the present invention in the first mine of Pingdingshan Coal Industry Group:

[0130] 1. Project introduction: With the continuous increase of mining depth, the conditions for mining resources are becoming more and more difficult. The problem of roadway support stability caused by deep mine mining is difficult to overcome, especially the large buried depth, complex structure and superimposed pressure under mining pressure, the roadway support is even more difficult. These pressures are caused by the difference in the speed of time, the magnitude and direction of the force, etc., so it is a combination of unequal time and uneven superimposed pressure. Under the action of this uneven superimposed pressure, the roadway support is often repeatedly damaged, so it is more and more difficult to keep the roadway support stable.

[0131]2. According to the site conditions, the support system is proposed and established: the loose composite surrounding rock mass w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com