Special floor for magnesium container house and manufacturing method of special floor

A container and floor technology, which is applied in the field of special floors for magnesium container houses, can solve the problems of easy deformation and cracking of solid wood floors, health hazards of users, and susceptibility to moisture, and achieve excellent impermeability, reduced energy consumption, and stable chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

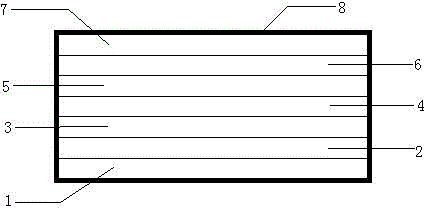

[0036] Such as figure 1 Shown is a schematic diagram of the structure of the present invention, the present invention is a special floor for a magnesium container house, which is characterized in that: from bottom to top, it includes a primer layer 1, a lower non-woven fabric layer 2, a lower glass fiber layer 3, and a middle material Layer 4, upper glass fiber layer 5, upper non-woven fabric layer 6 and decorative layer 7; primer layer 1, lower non-woven fabric layer 2, lower glass fiber layer 3, middle material layer 4, upper glass fiber layer 5, upper The exposed surfaces of the non-woven fabric layer 6 and the decorative layer 7 are coated with a waterproof sealing layer 8 .

[0037] Its manufacturing method is:

[0038] (1) Prepare the floor mold and preheat it to 40°C.

[0039] (2) Add primer raw materials to the floor mold, and stir evenly, as primer layer 1; the components of the primer raw materials and the mass percentages of each component are: magnesium oxide: 15...

Embodiment 2

[0048] Such as figure 1 Shown is a schematic diagram of the structure of the present invention, the present invention is a special floor for a magnesium container house, which is characterized in that: from bottom to top, it includes a primer layer 1, a lower non-woven fabric layer 2, a lower glass fiber layer 3, and a middle material Layer 4, upper glass fiber layer 5, upper non-woven fabric layer 6 and decorative layer 7; primer layer 1, lower non-woven fabric layer 2, lower glass fiber layer 3, middle material layer 4, upper glass fiber layer 5, upper The exposed surfaces of the non-woven fabric layer 6 and the decorative layer 7 are coated with a waterproof sealing layer 8 .

[0049] Its manufacturing method is:

[0050] (1) Prepare the floor mold and preheat it to 45°C.

[0051] (2) Add primer raw materials to the floor mold, and stir evenly, as primer layer 1; the components of the primer raw materials and the mass percentages of each component are: magnesium oxide: 20...

Embodiment 3

[0060] Such as figure 1 Shown is a schematic diagram of the structure of the present invention, the present invention is a special floor for a magnesium container house, which is characterized in that: from bottom to top, it includes a primer layer 1, a lower non-woven fabric layer 2, a lower glass fiber layer 3, and a middle material Layer 4, upper glass fiber layer 5, upper non-woven fabric layer 6 and decorative layer 7; primer layer 1, lower non-woven fabric layer 2, lower glass fiber layer 3, middle material layer 4, upper glass fiber layer 5, upper The exposed surfaces of the non-woven fabric layer 6 and the decorative layer 7 are coated with a waterproof sealing layer 8 .

[0061] Its manufacturing method is:

[0062] (1) Prepare the floor mold and preheat it to 50°C.

[0063] (2) Add primer raw materials to the floor mould, and stir evenly, as primer layer 1; the components of the primer raw materials and the mass percentages of each component are: magnesium oxide: 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com