Ecological fireproof interior trimming plate and manufacturing method of ecological fireproof interior trimming plate

An interior panel and ecological technology, applied in the field of ecological fireproof interior panels, can solve the problems of poor weather resistance, fire prevention, poor heat preservation and sound insulation, poor quality of life in container houses, etc., and achieve strong weather resistance, good flame retardant and fire prevention effects , Excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

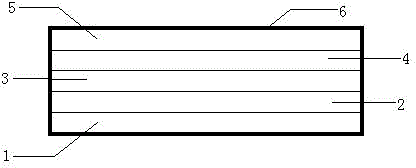

[0029] Such as figure 1 Shown is a schematic structural diagram of the present invention, the present invention is an ecological fireproof interior trim panel, characterized in that: from bottom to top respectively comprises a bottom material layer 1, a middle material layer 2, a glass fiber layer 3, a non-woven layer 4 and an inner Decorative layer 5.

[0030] Its production method is:

[0031] (1) Wrap a layer of non-woven fabric on the outside of the PVC board to make the bottom layer 1.

[0032] (2) Making the middle material layer 2: add the middle material layer raw materials to the middle material layer mold, and solidify into the middle material layer 2; lay the middle material layer 2 on the top of the bottom material layer 1, and use a roller to squeeze; the middle material The composition and mass percentage of each component are: sawdust: 10%, perlite: 10%, fly ash: 12%, magnesium oxide: 25%, magnesium chloride solution: 25%, crushed scrap: 13% , Modifier: 2%; w...

Embodiment 2

[0039] Such as figure 1 Shown is a schematic structural diagram of the present invention, the present invention is an ecological fireproof interior trim panel, characterized in that: from bottom to top respectively comprises a bottom material layer 1, a middle material layer 2, a glass fiber layer 3, a non-woven layer 4 and an inner Decorative layer 5.

[0040] Its production method is:

[0041] (1) Wrap a layer of non-woven fabric on the outside of the PVC board to make the bottom layer 1.

[0042] (2) Making the middle material layer 2: add the middle material layer raw materials to the middle material layer mold, and solidify into the middle material layer 2; lay the middle material layer 2 on the top of the bottom material layer 1, and use a roller to squeeze; the middle material The composition of layer raw materials and the mass percentage of each component are: sawdust: 15%, perlite: 5%, fly ash: 12%, magnesium oxide: 30%, magnesium chloride solution: 25%, crushed scr...

Embodiment 3

[0049] Such as figure 1 Shown is a schematic structural view of the present invention, the present invention is an ecological fireproof interior panel, characterized in that: from bottom to top respectively comprises bottom material layer 1, middle material layer 2, glass fiber layer 3, non-woven layer 4 and inner Decorative layer 5.

[0050] Its production method is:

[0051](1) Wrap a layer of non-woven fabric on the outside of the PVC board to make the bottom layer 1.

[0052] (2) Making the middle material layer 2: Add the middle material layer raw materials to the middle material layer mold, and solidify into the middle material layer 2; lay the middle material layer 2 on the top of the bottom material layer 1, and use a roller to squeeze; the middle material The composition and mass percentage of each component are: sawdust: 15%, perlite: 10%, fly ash: 12%, magnesium oxide: 22%, magnesium chloride solution: 26%, crushed scrap: 13% , Modifier: 2%; Wherein the compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com