Non chain pillar gob-side entry retaining method with filling wall self-erasure

A wall filling and self-elimination technology, which is applied in the direction of filling, earthwork drilling, gas discharge, etc., can solve the problems of limiting the pressure relief range of the protective layer of the close-distance coal seam group, hindering the development of continuous pressure relief mining technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

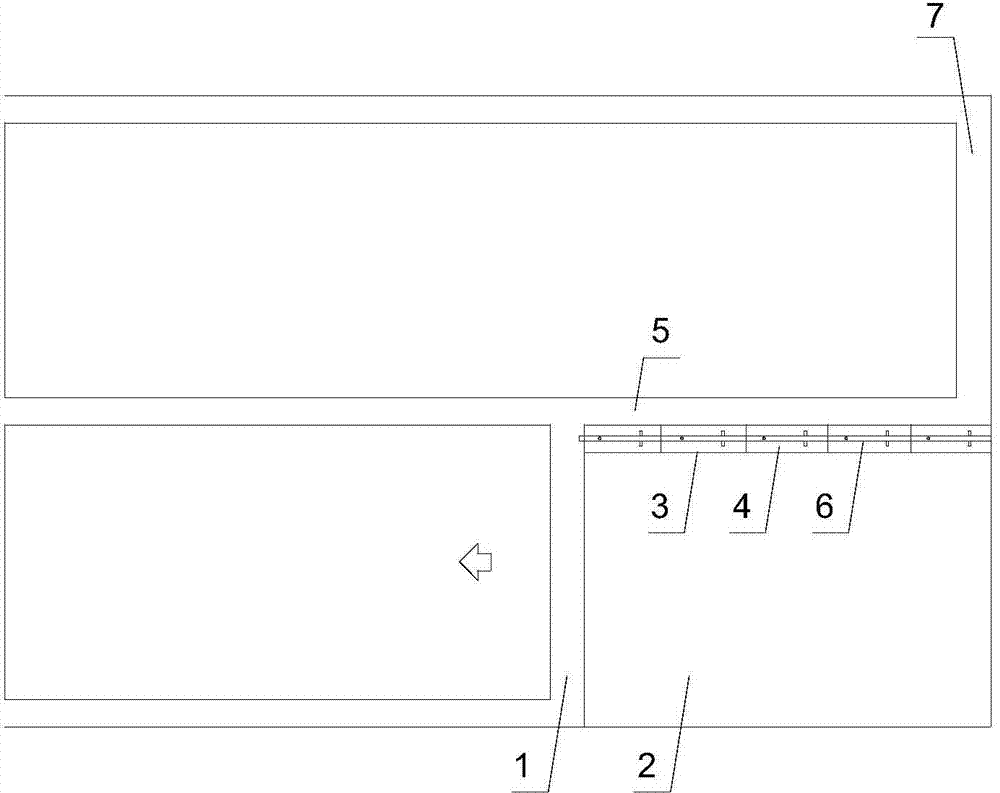

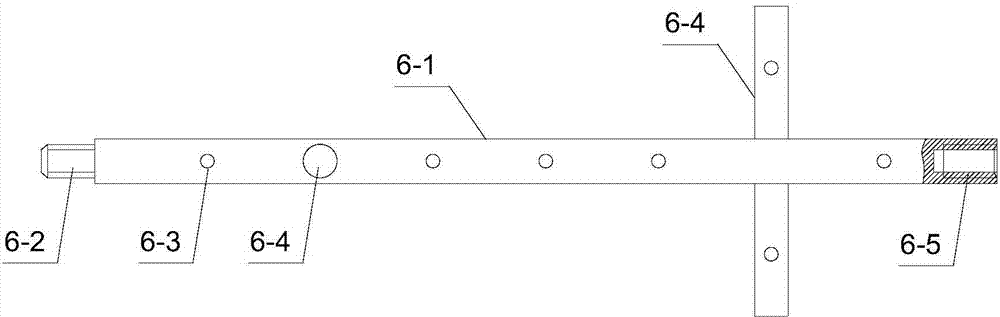

[0024] Such as figure 1 As shown, the roadside wall self-elimination method for retaining roadway without coal pillars along the goaf according to the present invention, when mining the coal mining face 1 in the upper section, pumps along the edge of the goaf 2 into the flexible mold bag 3 Send high-water materials to construct the filling wall 4 beside the roadway, and preset the ventilation pipe 6 in the filling wall 4. When mining the coal mining face 7 in the lower section, the flexible mold bag behind the coal mining face 7 3. Cutting. After the mining is completed, inject carbon dioxide into the vent pipe 6 to impel the filling wall to undergo carbonization reaction and break up and decompose, so as to realize the self-elimination of the roadside wall. The specific implementation steps are as follows:

[0025] a. In the process of mining the coal mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com