Installation device and method of U-shaped beam in shield type TBM

A technology of installation device and installation method, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., and can solve the problem that U-shaped beams cannot be tightly attached to the cave wall, joints are not firmly connected, and the curvature of U-shaped beam installers and excavation holes Problems such as wall mismatch can be solved to achieve the effect of improving tunneling efficiency, improving installation efficiency, and ensuring installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

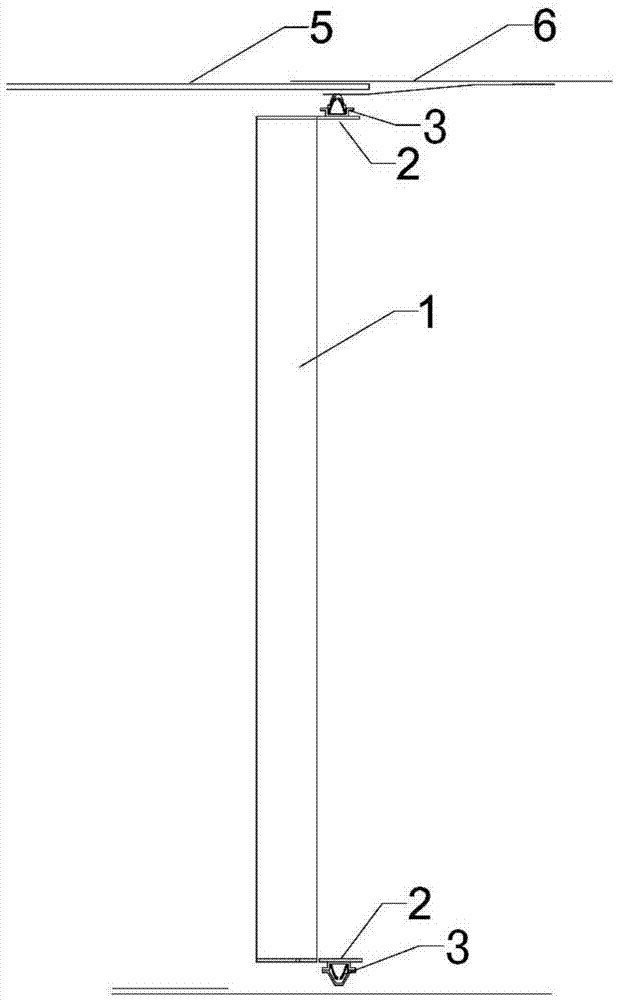

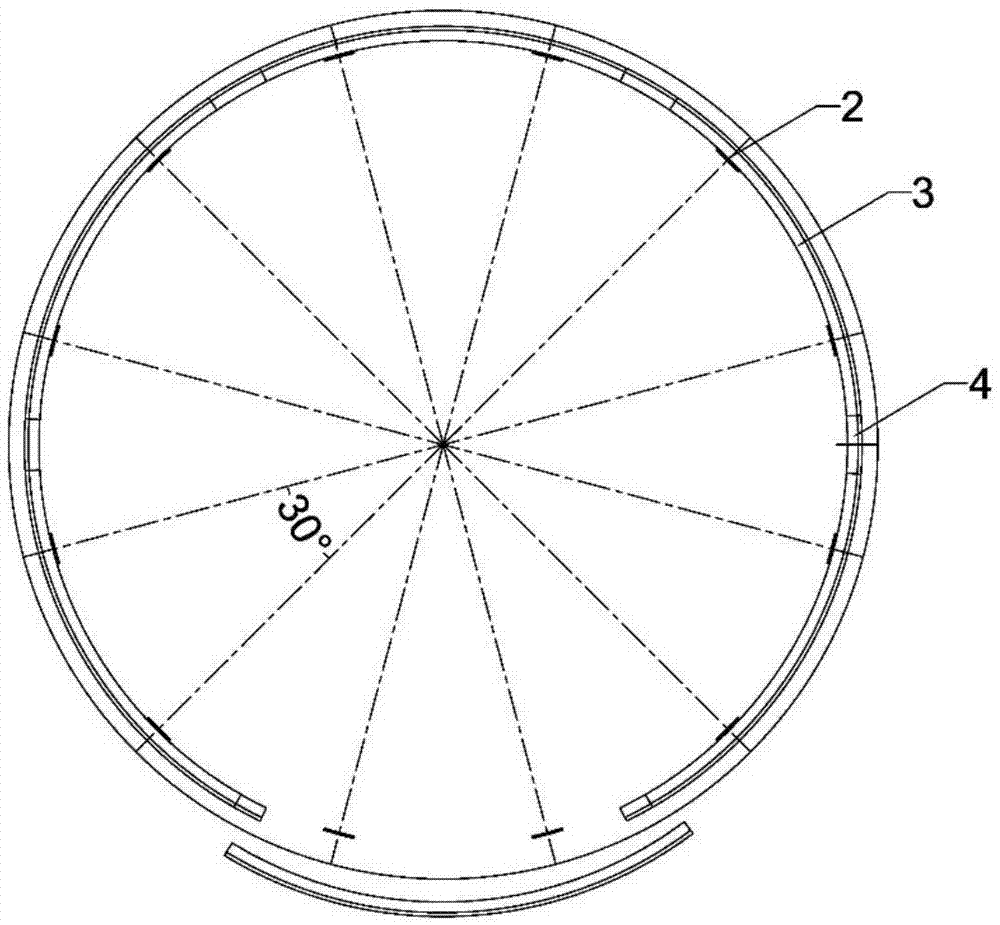

[0027] see Figure 1 to Figure 2 , a U-shaped beam installation device in a shield-type TBM, including a U-shaped beam installer 1 arranged in a tunnel, and a protective shield 5 is provided between the U-shaped beam installer 1 and the surrounding rock excavation wall 6 at the top of the tunnel , the U-shaped beam installer 1 is cylindrical, and twelve arc-shaped steel plates 2 are welded and fixed on the outer edge of the U-shaped beam installer 1, and the two ends of each arc-shaped steel plate 2 are connected with the center of curvature The included angles are all 30°, the curved steel plate 2 forms a cylinder whose radius of curvature is equal to the outer diameter of the U-shaped beam installer 1, and the outer side of the curved steel plate 2 is provided with six U-shaped beams 3, and the adjacent U-shaped beams 3 The profile beams 3 are connected by joints 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com