A Coordinated Control Method of Pressure Relief Support in Deep High Stress Roadway Based on Drilling Pressure Relief

A drilling pressure relief and coordinated control technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems affecting popularization and application, control of unfavorable roadway surrounding rock creep, disturbance of roadway surrounding rock primary support structure, etc. , to achieve the effect of reducing cost, reducing repair rate and labor intensity of workers, and reducing large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

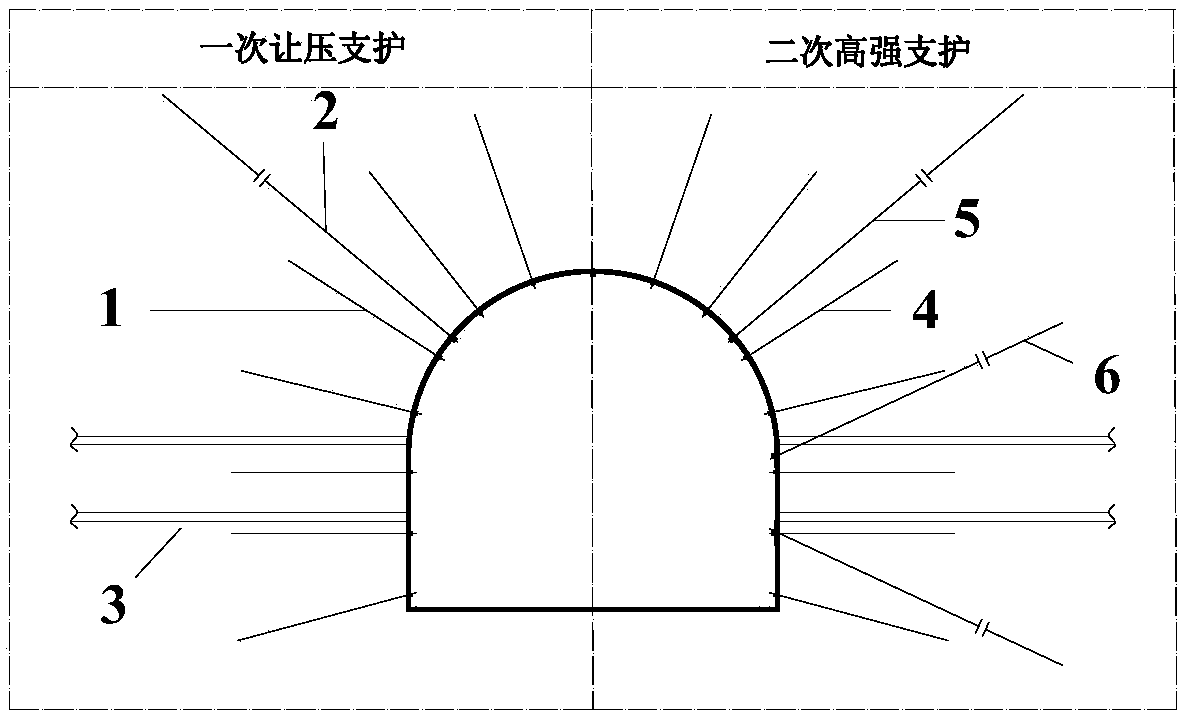

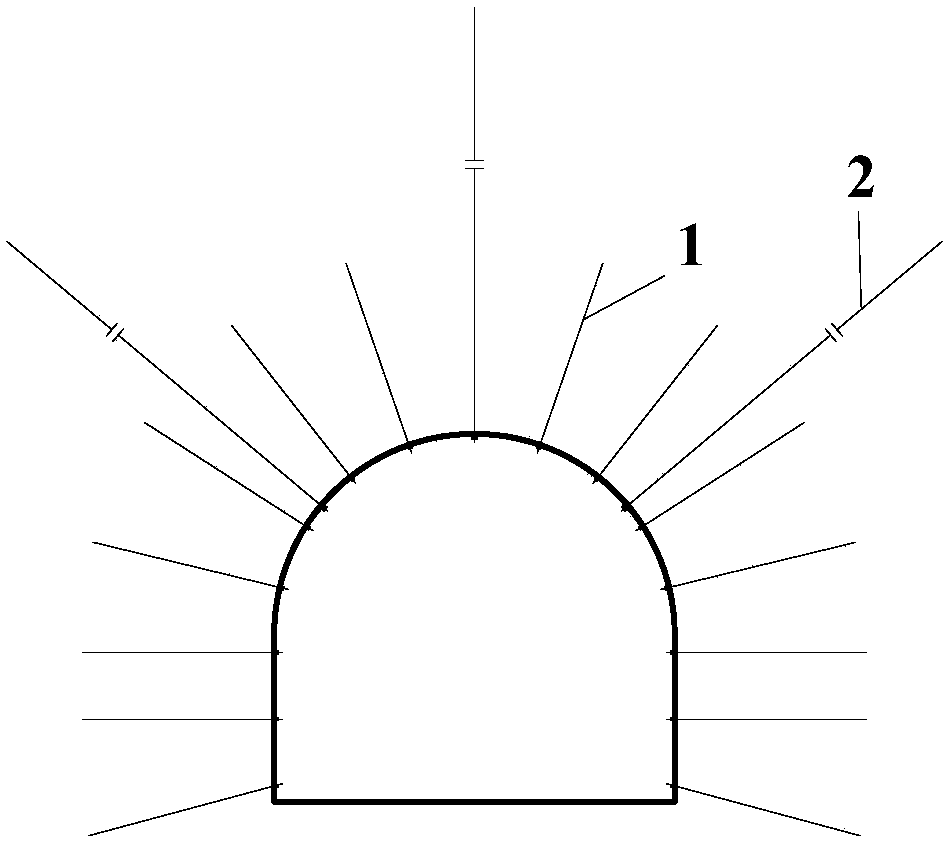

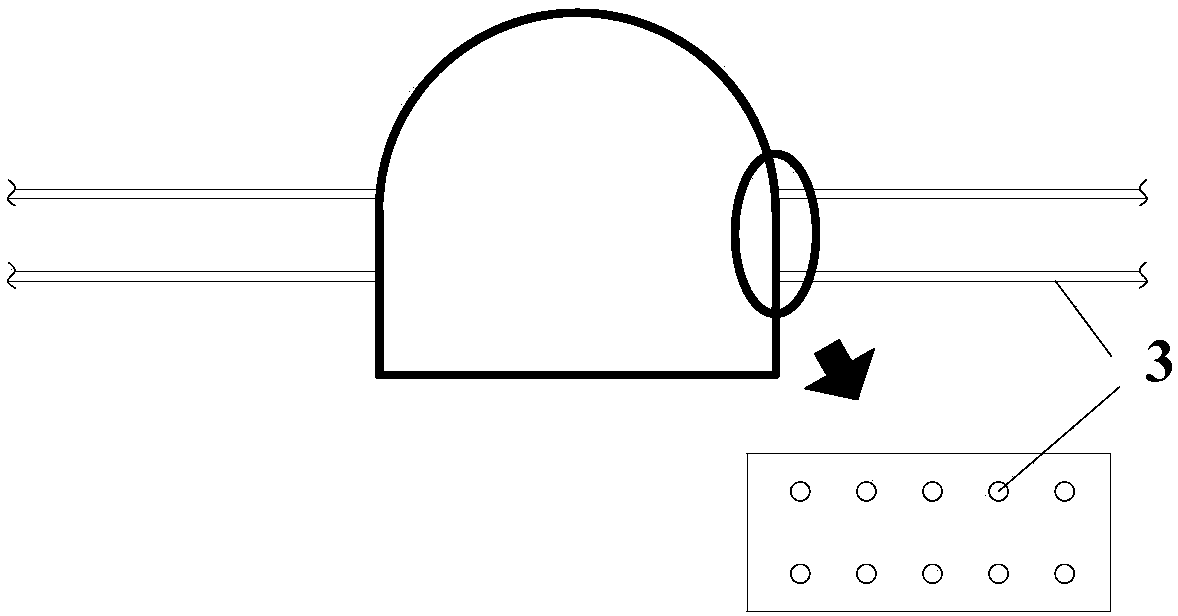

[0036] Refer to the following figure 1 , figure 2 , image 3 , Figure 4 , Figure 5To further illustrate the specific implementation of the present invention, a coordinated control method for deep high-stress roadway pressure relief and support based on drilling pressure relief, the method is divided into primary pressure relief support, drilling pressure relief and two There are three steps of sub-high-strength anchor-grouting support, the key point of which is to grasp the timing of drilling pressure relief and the timing of secondary anchor-grouting support. The concrete implementation steps of this method are as follows:

[0037] a. The test roadway is excavated by smooth blasting method. After the roadway is excavated, the floating gangue is quickly cleaned, and the working face is followed by a support. The high-strength yield anchor 1 and the high-strength yield anchor cable 2 are used to complete the deep high-stress roadway. initial support.

[0038] The imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com