Water-based drilling fluid suitable for high well temperature and low formation pressure coefficient

A technology of formation pressure coefficient and water-based drilling fluid, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of low-density drilling fluid sticking and cutting difficult to maintain, insufficient plugging ability, easy to collapse, etc. Achieve long-term stability, low unit cost, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] As a preferred embodiment of the present invention, it discloses a water-based drilling fluid suitable for high well temperature and low formation pressure coefficient, which consists of clear water, viscosifier, fluid loss reducer, plugging agent, stabilizer, pH Conditioner and weighting agent are prepared according to the ratio of parts by weight, clear water: viscosifier: fluid loss reducer: plugging agent: stabilizer: pH regulator: weighting agent = 100:10~15:15~25:9 ~15:1~2:0.5~1:35~60.

[0026] The tackifier is OCMA bentonite.

[0027] The fluid loss reducer is composed of 8-10 parts by weight of sulfonated phenolic resin SMP, 3-5 parts by weight of high temperature and salt-resistant fluid loss reducer RSTF, and 2-3 parts by weight of modified natural resin compound JNJS -220 blended.

[0028] The plugging agent is prepared by mixing 1-2 parts by weight of shale inhibitor SOLTEX, 2-3 parts by weight of modified resin bitumen YH-150, and 1-2 parts by weight of p...

Embodiment approach

[0036] As a best embodiment of the present invention, its preparation method is as follows: take clear water, viscosifier, fluid loss reducer, plugging agent, lubricant, pH regulator and weighting agent.

[0037] The specific ratio is: 400ml water, 48g OCMA soil, 60g SMP, 18g RSTF, 12g JNJS-220, 8g SOLTEX, 24g YH-150, 4g TYRF-1, 4g AB201, 3.2g caustic soda Weighted to 1.2g / cm 3 . After being fully stirred and mixed at 11000r / min, it was aged in a roller furnace at 130°C for 16 hours.

[0038] The measurement of basic performance parameters at 55°C is shown in Table 1:

[0039]

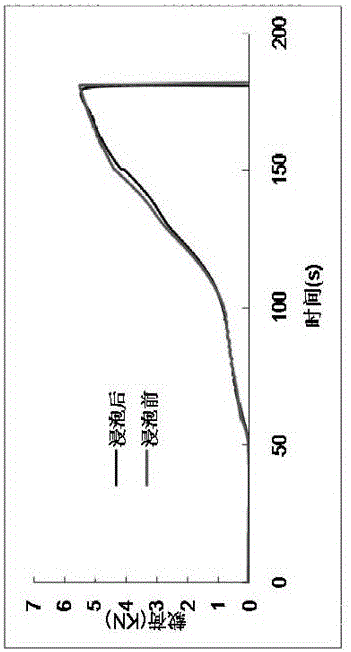

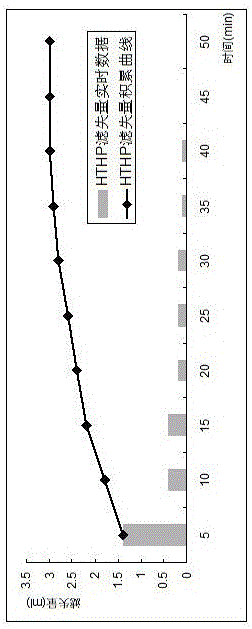

[0040] refer to figure 1 , The high-temperature and high-pressure filtration loss decreased significantly after 5 minutes and gradually decreased to zero after 40 minutes, achieving a good immediate plugging effect. Take out the formed filter cake, replace the drilling fluid with clean water and put it into the prepared high-performance drilling fluid high-temperature and high-pressure filter ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com