FRP (fiber reinforced plastic)-steel composite tube concrete column

A technology of concrete columns and composite pipes, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of unsatisfactory structural seismic performance, low axial stiffness of FRP pipes, and large lateral deflection, so as to shorten the construction period and save demolition costs. Die process, effect of good axial drawability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

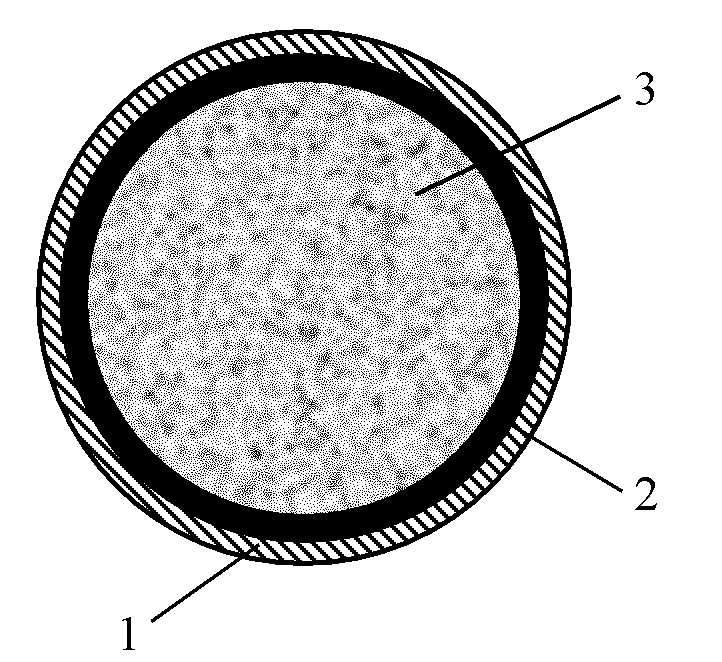

[0022] like figure 1 As shown, the cross-section of the FRP-steel composite pipe concrete column provided by the present invention is a circular structure, mainly composed of a circular FRP-steel composite pipe (circular FRP pipe 1 and circular steel pipe 2) and concrete 3 poured therein . (1) The steel pipe is welded by steel plates, and the two ends of the steel pipe are turned flat on a lathe to ensure the flatness and verticality of the two ends of the steel pipe. The geometric centers coincide and ensure the quality of the weld. (2) The FRP pipe is made by winding process: first, use coarse sandpaper or a grinding machine to derust the outer surface of the steel pipe; secondly, use acetone to clean the polished surface; finally, use the steel pipe as a winding mold and use continuous fiber yarn warp The FRP pipe is made by winding process (at this time, the FRP-steel composite pipe is also made at the same time), the fiber used is glass fiber, carbon fiber, basalt fiber...

Embodiment 2

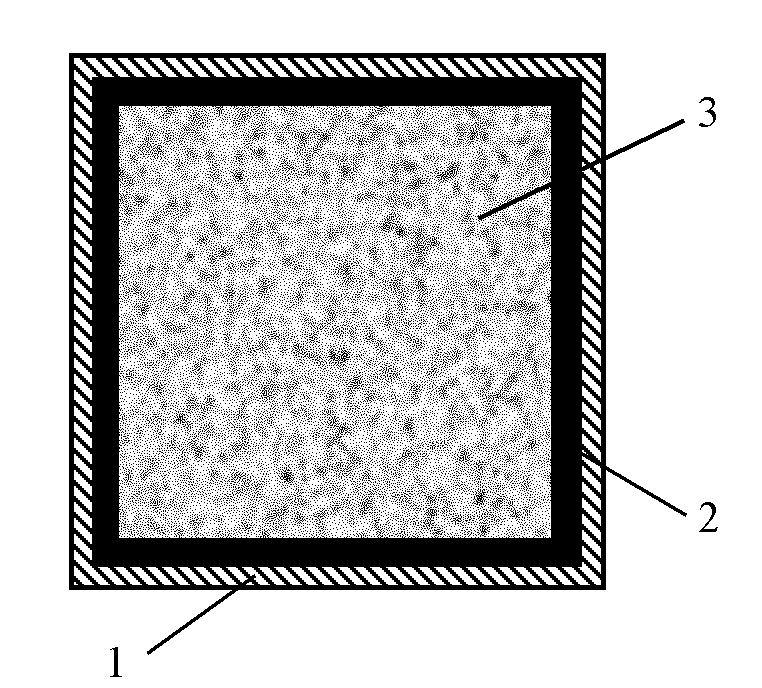

[0024] like figure 2 As shown, the cross-section of this FRP-steel composite pipe concrete column of the present invention is a square structure, mainly composed of square FRP-steel composite pipes (square FRP pipe 1 and square steel pipe 2) and concrete 3 poured therein. The method is the same as in Example 1.

Embodiment 3

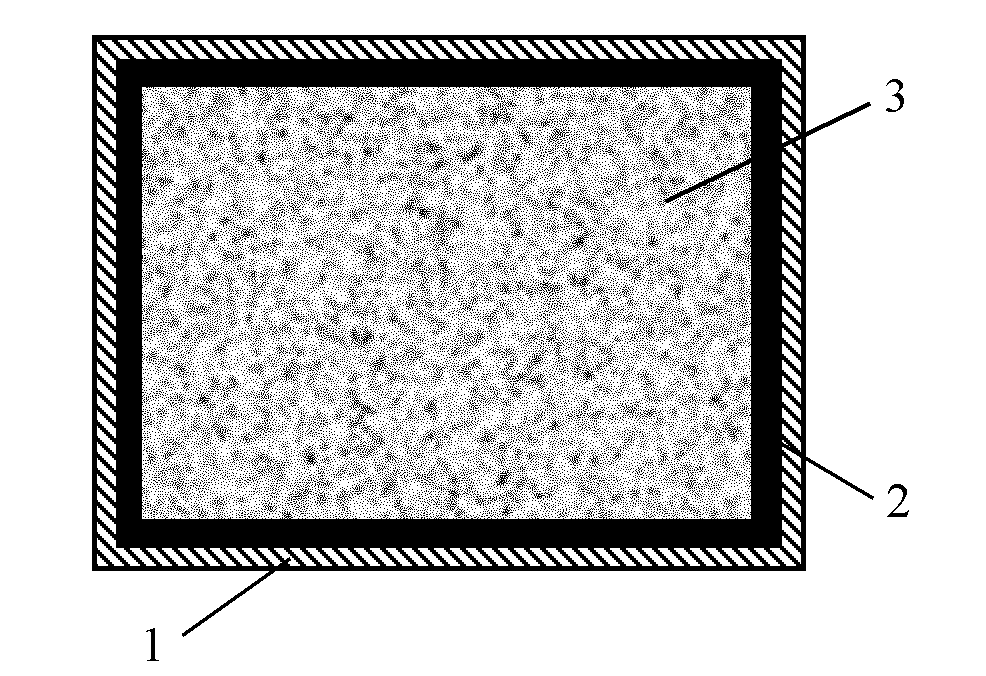

[0026] like image 3 As shown, the cross-section of this FRP-steel composite pipe concrete column of the present invention is a rectangular structure, mainly composed of a rectangular FRP-steel composite pipe (rectangular FRP pipe 1 and rectangular steel pipe 2) and concrete 3 poured into it. The method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com