Foundation ditch composite concrete nail supporting structure and method

A composite soil nailing and supporting structure technology, applied in foundation structure engineering, excavation, sheet pile wall, etc. Pressure performance, improve the effect of safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

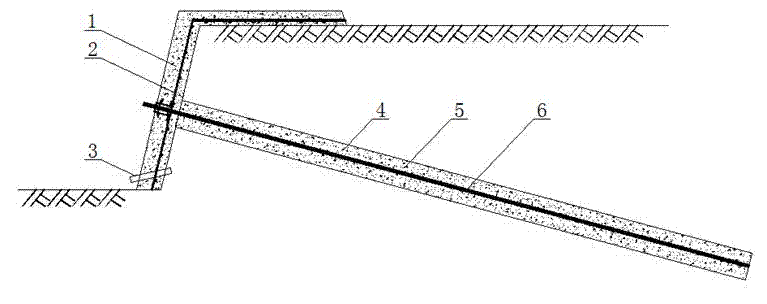

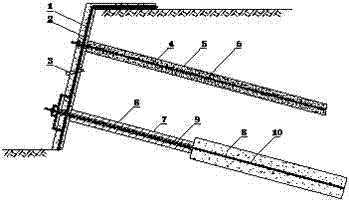

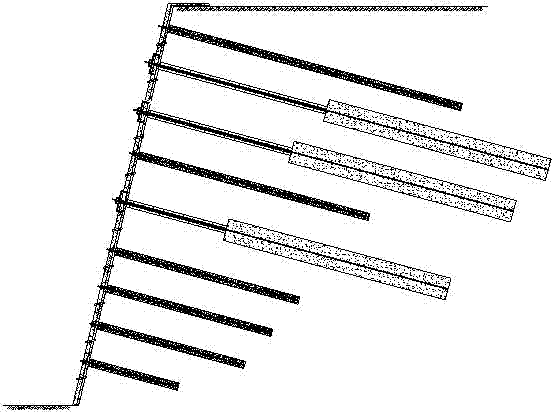

[0070] A kind of foundation pit composite soil nail supporting structure that the present invention proposes has the soil nail 6 that is fixed in the foundation pit wall soil nail borehole 4, the anchor rod 10 that is fixed in the foundation pit wall anchor rod borehole 7, in the foundation pit The surface of the wall is laid with reinforced mesh 2 sprayed concrete and constitutes the retaining surface layer; the soil nails are arranged at intervals in one layer, and the anchor rods are arranged at intervals in the other layer; between the soil nail heads and the reinforced mesh 2 The bearing structure under nailing is installed, and the bearing structure under nailing includes two parallel channel steels 11 arranged on the reinforcement mesh 2, a backing plate 13 placed in the middle of the two parallel channel steels, and the two parallel channel steels 11. The lower flange connecting steel bar 14 and the upper flange connecting steel bar 22 are connected as a whole, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com