Head car body structure of high-floor tramcar

A tram and car body structure technology, applied in the field of rail vehicles, can solve the problems of increasing noise transmission path, reducing ride comfort, and small space in the car, so as to reduce noise transmission path, improve ride comfort, The effect of reducing the amount of material used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

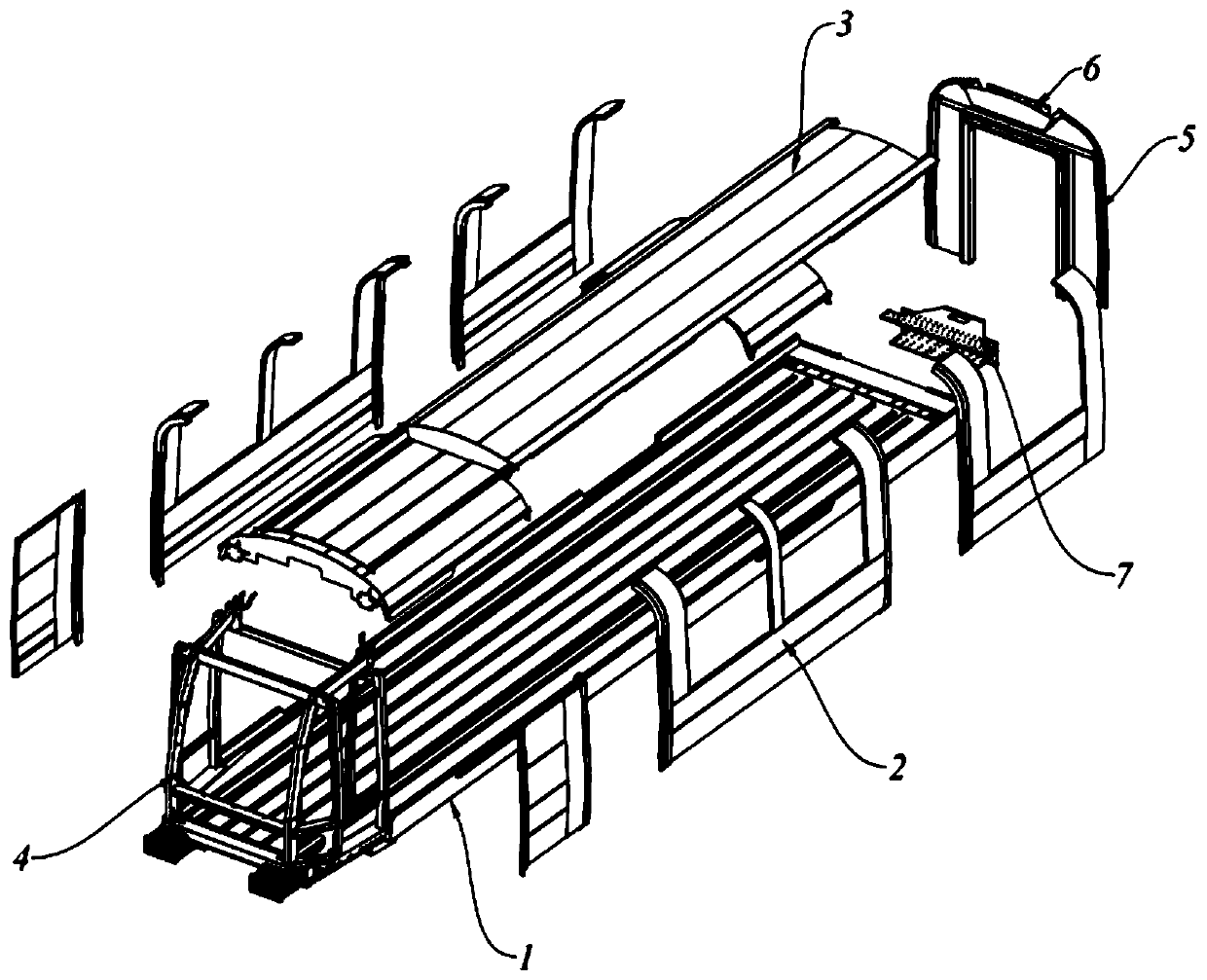

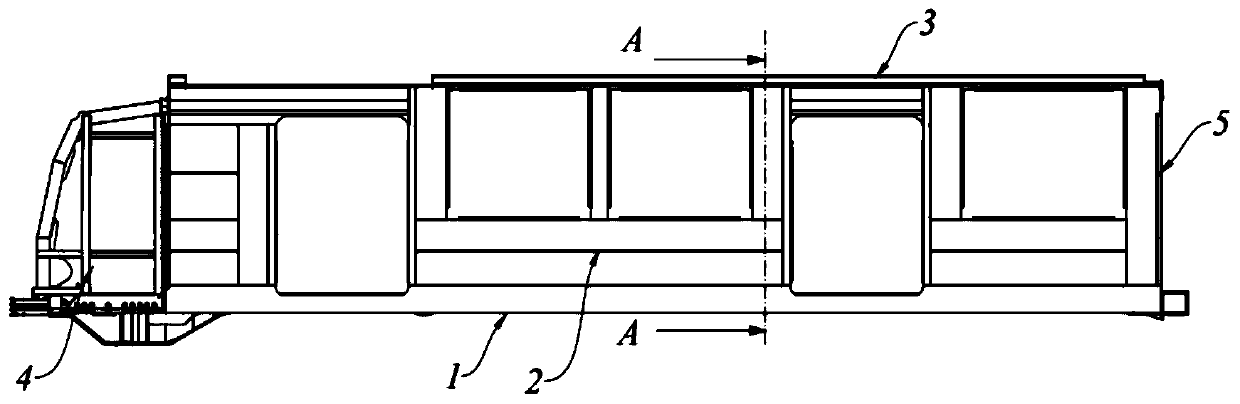

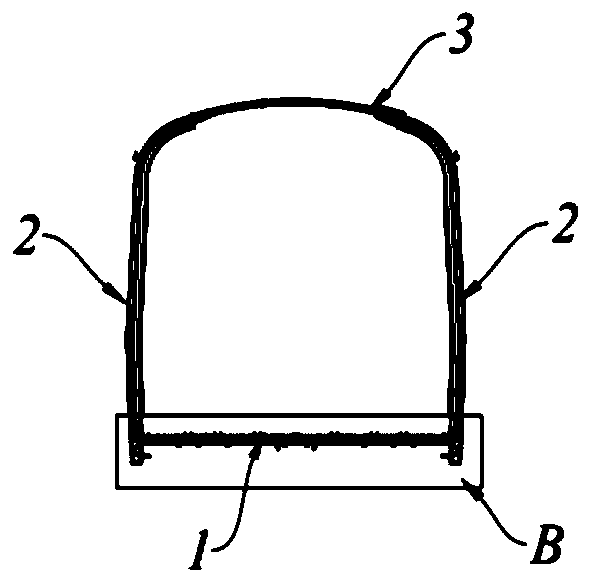

[0038] Please refer to figure 1 and figure 2 , the present invention includes:

[0039] A head car body structure of a high-floor tram, comprising: an underframe 1, a side wall 2, a roof 3, a cab 4, an end wall 5, an upper hinged seat 6 and a lower hinged seat 7, the underframe 1. The side wall 2, the roof 3 and the end wall 5 are connected by welding, the cab 4 is connected with the underframe 1 and the roof 3 by bolts, the upper hinge seat 6 is connected with the end wall 5 by rivets, and the The lower hinged seat 7 is connected with the chassis 1 through rivets;

[0040] Wherein, the bodies of the underframe 1, the side wall 2, the roof 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com