Offshore six buoy and six buoyancy tank combined type foundation structure and construction method thereof

A combined foundation and basic structure technology, applied in the field of basic structure of marine engineering, can solve problems such as construction, transportation mode and cost constraints, subsidence not in place, skirt plate and other steel structure buckling, etc., to increase anti-slip stability high stability, small water plane area, and the effect of improving lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

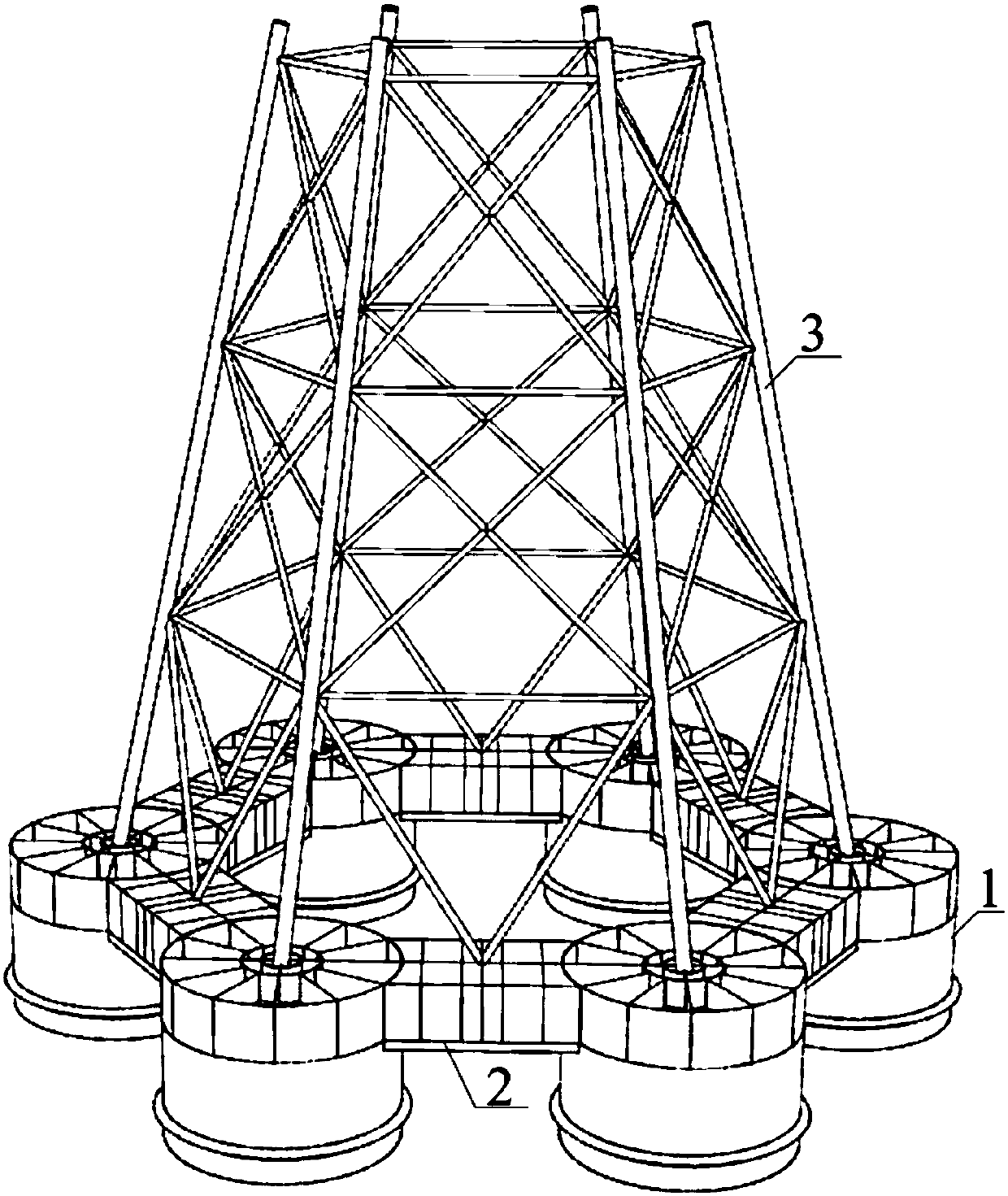

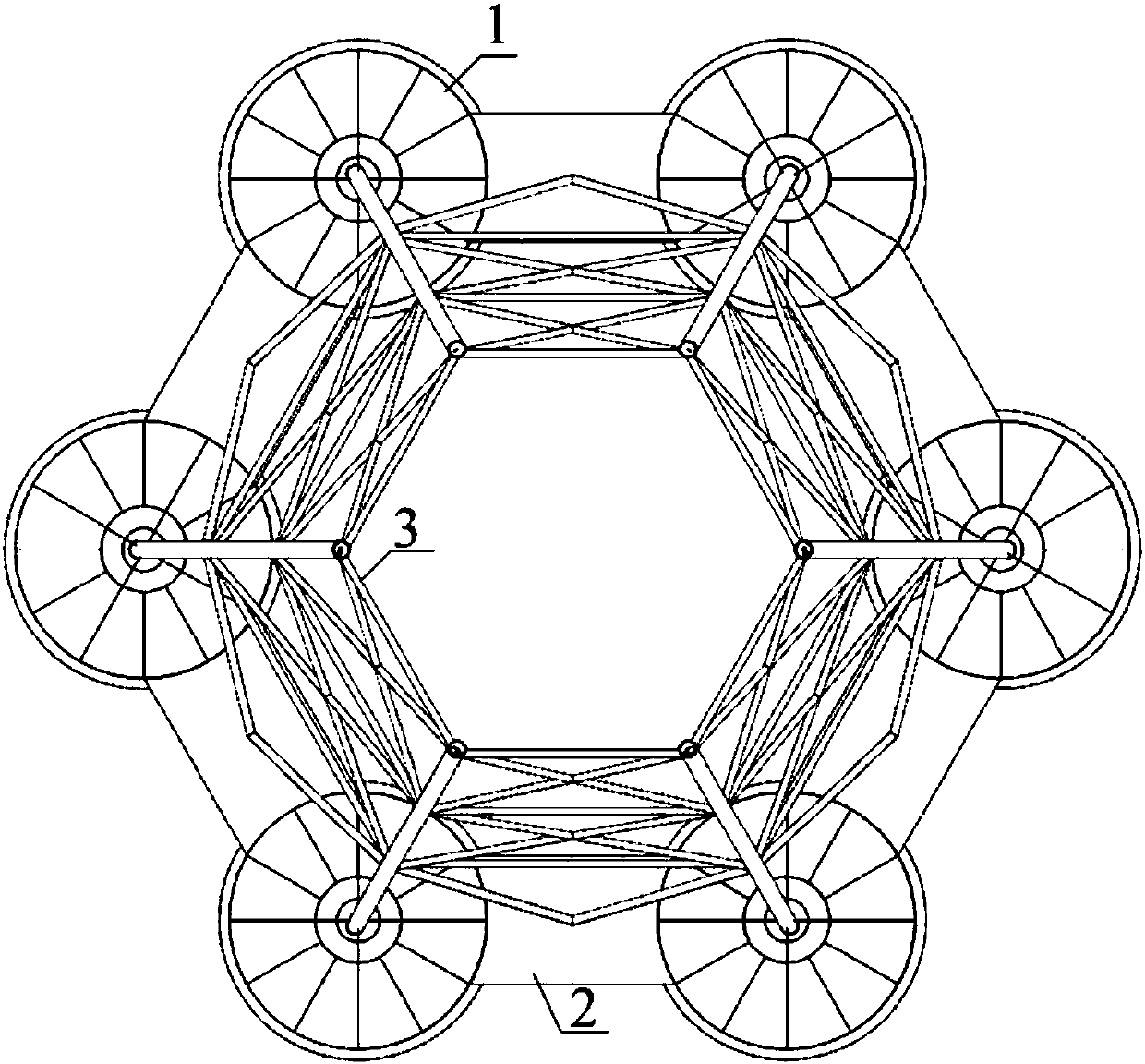

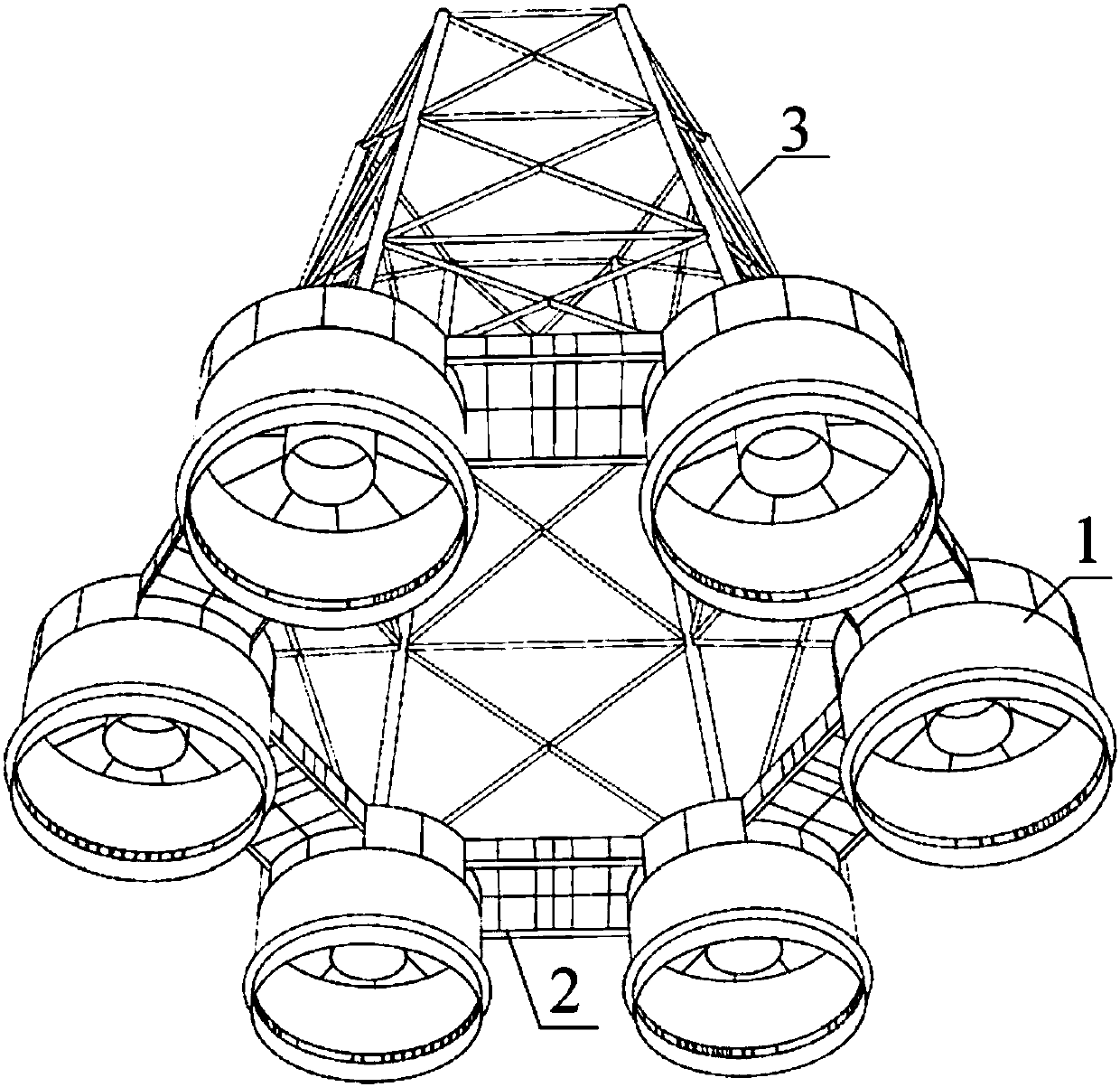

[0036] Such as Figure 1 to Figure 3 As shown, this embodiment discloses a combined foundation structure of six buoys and buoys at sea, which mainly includes six identical buoys 1 , six identical buoys 2 , and a transition section tower 3 .

[0037] The six buoys 1 are connected successively according to their center points on the horizontal plane and can be arranged in a regular hexagon.

[0038] Such as Figure 4 As shown, each pontoon 1 is composed of a pontoon top cover 11 , a cylinder wall 12 , a cylinder skirt 13 , a radial rib 14 , a circumferential rib 15 , an annular inner skirt 16 , and a soil shearing ring 17 . The upper edge of the circular buoy cover 11 is provided with an annular tube wall 12, and the lower edge is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com