A combined multi-tube jacket foundation structure and its construction method

A basic structure and jacket technology, which is applied to the multi-tube composite basic structure and its construction field, can solve the problems of large diameter of the cylindrical foundation, and achieve the effects of good integrity, easy recovery and strong bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

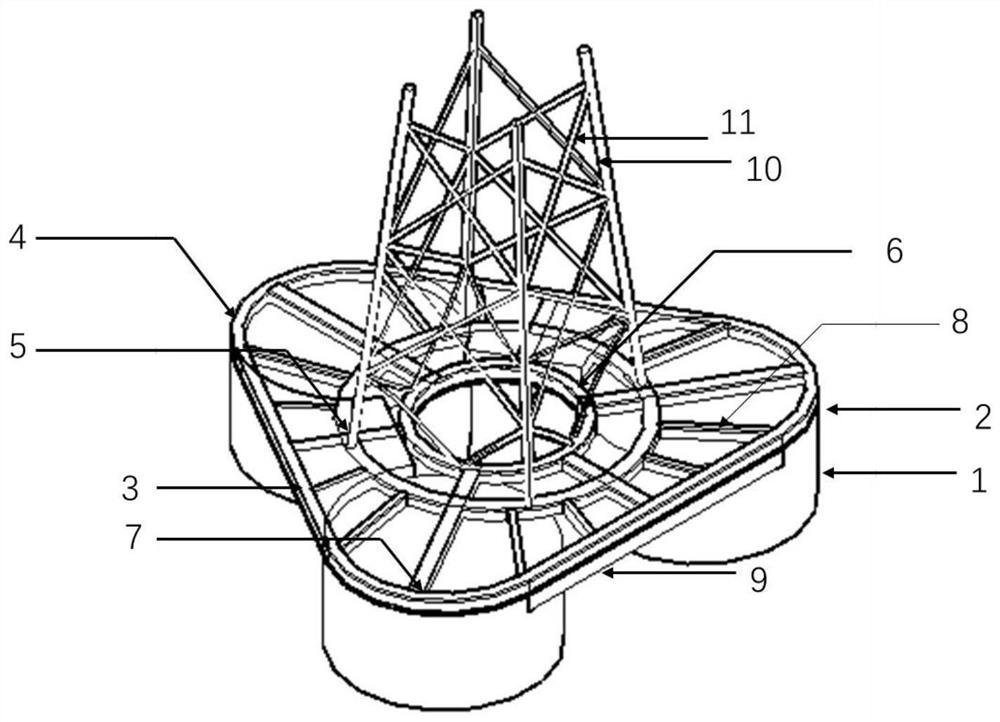

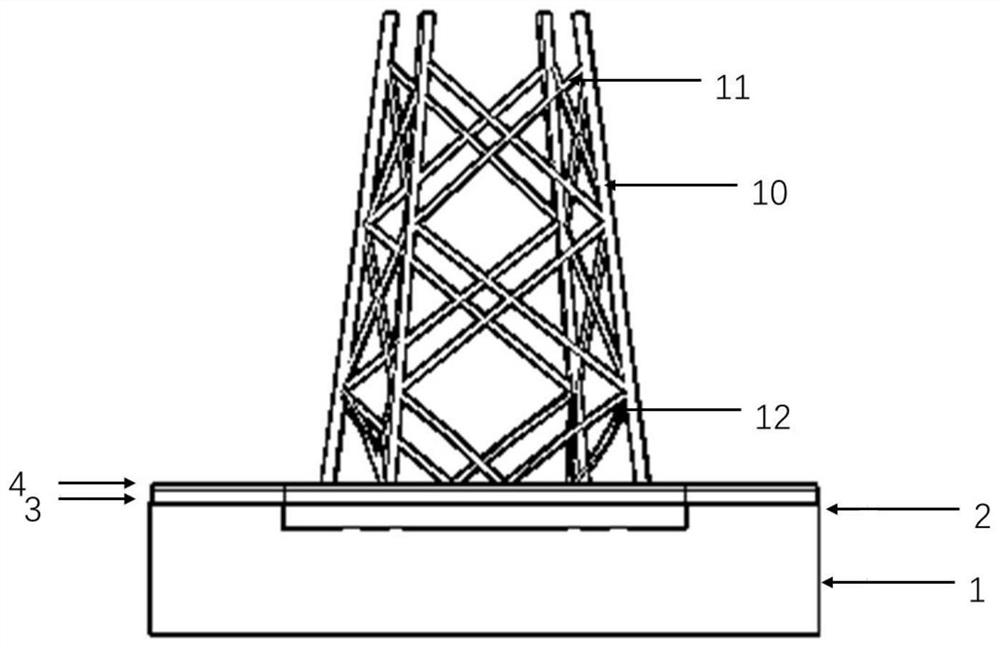

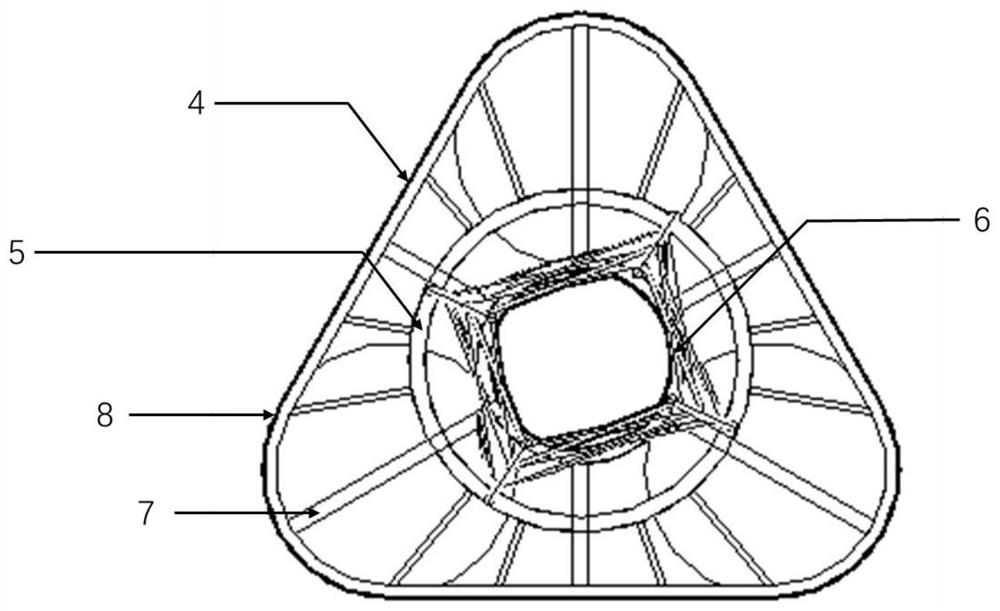

[0035] Such as Figure 1 to Figure 3 As shown, this embodiment discloses a combined multi-tube jacket foundation structure, including a plurality of identical steel tubes 1, a steel roof 2, a concrete slab 3, an outer ring beam 4, a middle ring beam 5, an inner ring beam 6, Concrete main beam 7, concrete secondary beam 8, steel groove 9, column 10, support rod 11, oblique rod 12.

[0036] A plurality of identical steel cylinders 1 are arranged on the horizontal plane to form a regular polygon according to the line connecting their center points, and are welded together with the steel top plate 2 at the upper part. The number of steel cylinders 1 is generally 3-8; the steel cylinder 1 is a steel cylindrical structure with a radius of 10-15m a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com