Floating LNG (liquefied natural gas) liquefying factory ship bottom-supported foundation structure and construction method thereof

A basic structure and bottom-sealing technology, which is applied in basic structure engineering, construction, etc., can solve problems such as damage, unsafe floating LNG liquefaction plant ships sitting directly on the bottom, broken keel structures, etc., to avoid stress concentration and improve skid resistance The effect of shifting stability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

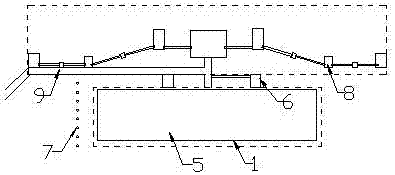

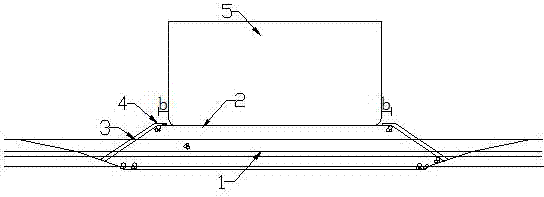

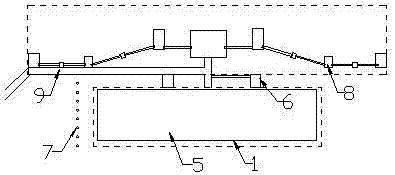

[0027] Such as Figure 1-2 As shown, the present invention provides a foundation structure for a floating LNG liquefaction plant, including a riprap foundation bed 1, a rubber steel backing plate 2, a bottom protection block 3 and a top fence plate 4, and the foundation for a floating LNG liquefaction plant The structure is a riprap foundation structure; the riprap foundation bed 1 adopts block stones that are easy to be compacted and well-graded, and should be located on the bearing layer with better foundation bearing capacity; the rubber steel backing plate 2 is located on the riprap foundation On the upper part of the bed 1, the floating LNG liquefaction plant ship 5 is directly located on the upper part of the rubber steel backing plate 2. The overall plane size of the floating LNG liquefaction plant ship 5 is 250m*60m, and the molded depth is 30m. The total plane size of the bottom foundation is 256m*66m, and the top elevation of the bottom foundation should be determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com