Method for quickly constructing stress-saturated protolith crustal stress test standard part

A test standard, ground stress technology, applied in the preparation of test samples, force/torque/work measuring instruments, force sensors in the holes of the force-bearing structure, etc., can solve the problem that the test accuracy and accuracy cannot be guaranteed, and It can solve the problems of long sampling time, etc., to achieve the effect of promising prospects, avoiding stress dissipation, and reducing test difficulty and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

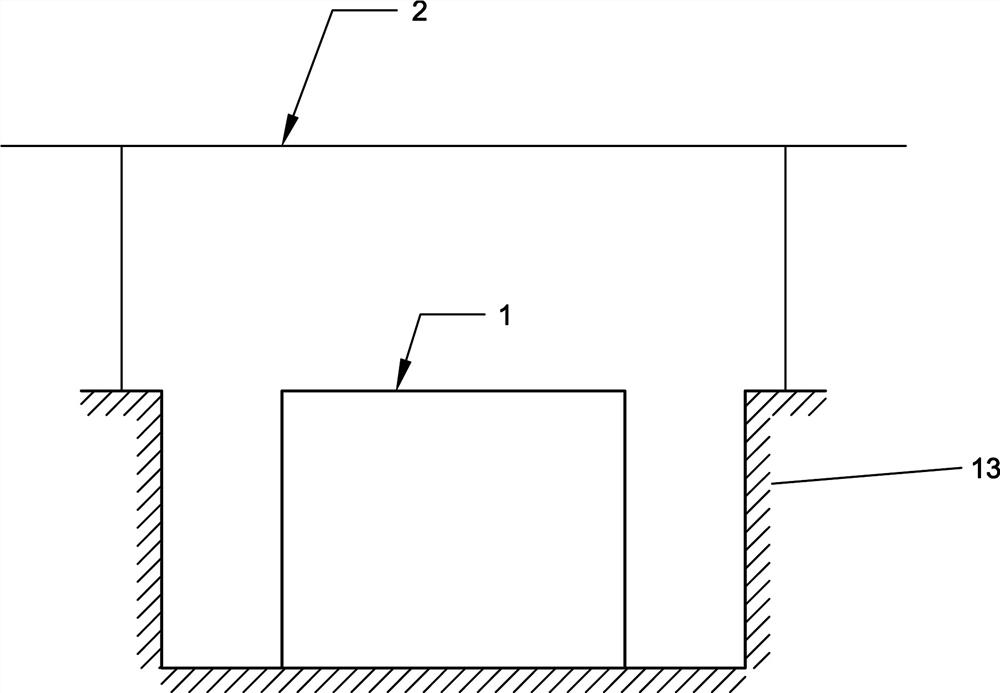

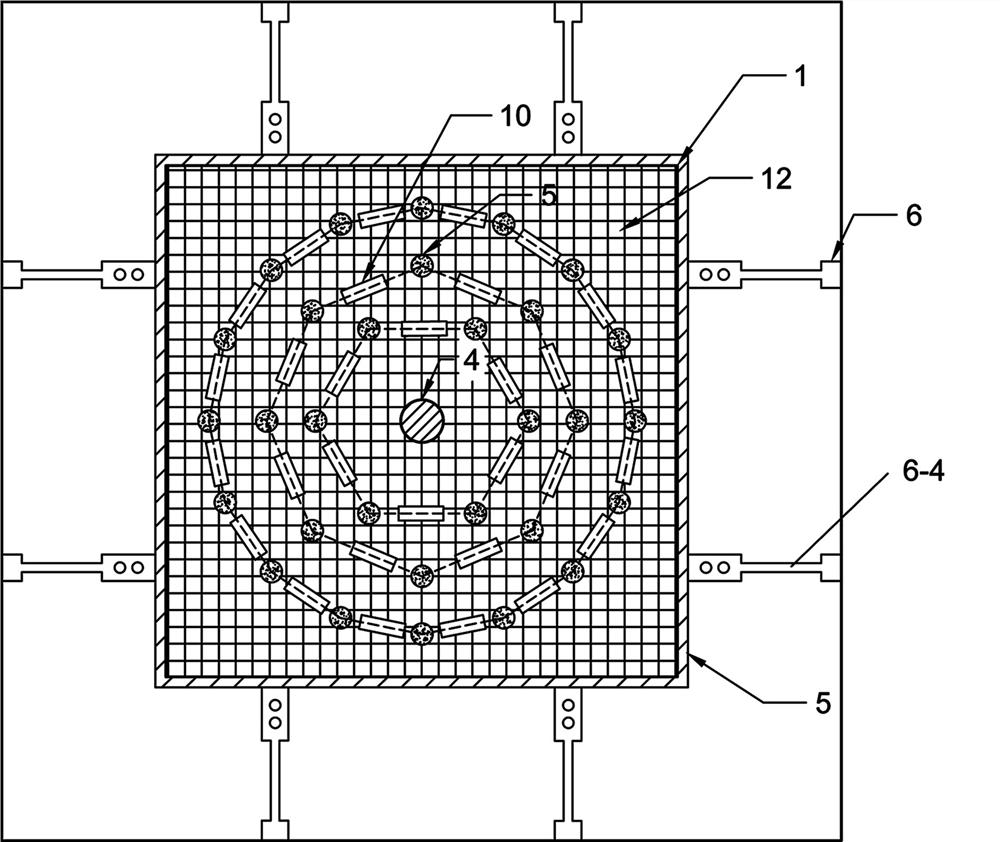

[0041] Such as figure 1 , figure 2 and image 3 As shown, when the ground stress test method needs to be tested in the horizontal direction:

[0042] A method for rapidly constructing stress-saturated in-situ stress test standard parts, the method comprising the following steps:

[0043] Step 1: Select sandstone rock mass 13 in situ on site, and prepare site original rock sample 1;

[0044] The method is as follows: select a sandstone rock mass 13 in situ at the site, dig a working face with a certain depth around the sandstone rock mass 13, and obtain the original rock sample 1 on site;

[0045] After making the original rock sample 1 on site, a canopy 2 is built above the rock sample.

[0046] Step 2: Drill the main stress hole 4 and the monitoring auxiliary hole 5 on the original rock sample 1 at the site. The depth of the stress main hole 4 and the monitoring auxiliary hole 5 are both 3 meters. The layout of the stress main hole 4 and the monitoring auxiliary hole 5 ...

Embodiment 2

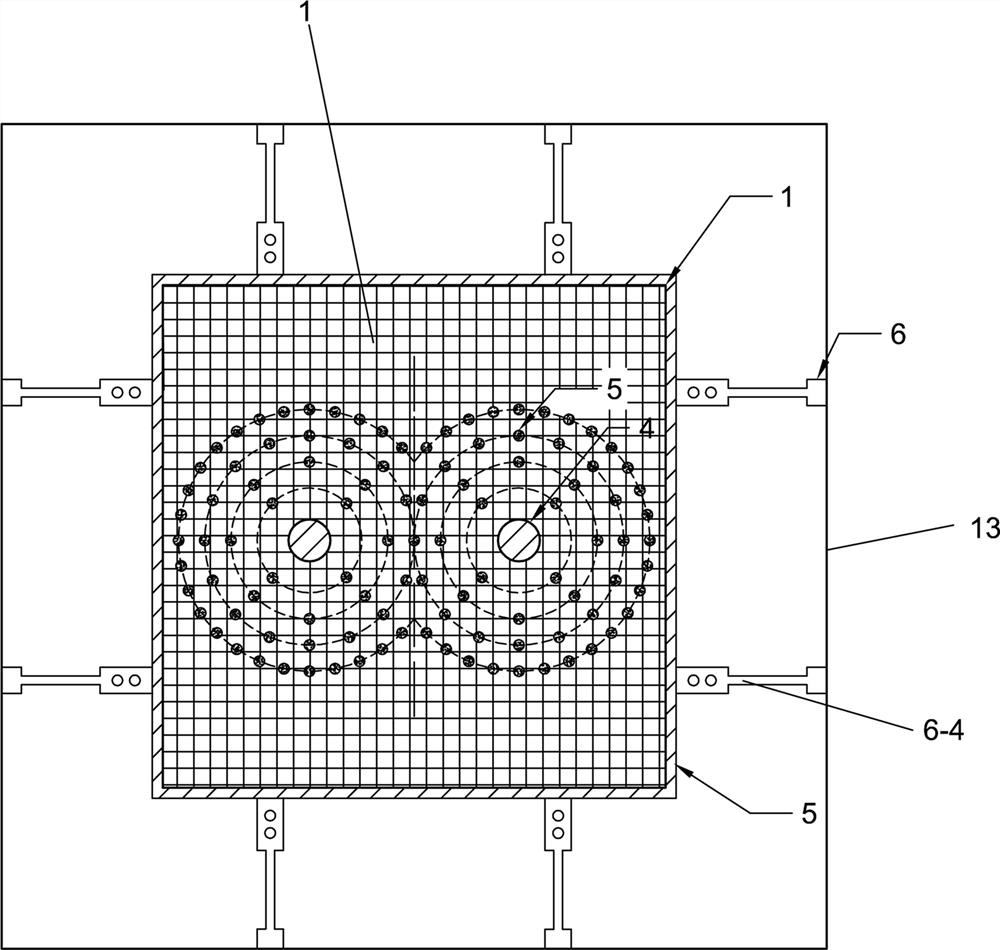

[0062] Such as figure 1 and Figure 4 As shown, when the ground stress test method needs to be tested in the horizontal direction:

[0063] The layout of the stress main hole 4 and the monitoring auxiliary hole 5 in step 2 can also be: the number of the stress main hole 4 is two, which are set at 1 / 3 and 2 / 3 of the central axis of the upper surface of the original rock sample 1 on site , the number of monitoring auxiliary holes 5 is multiple, with each stress main hole 4 as the center, surrounding the stress main hole 4 in a plurality of circles uniformly arranged.

[0064] All the other steps are the same as in Embodiment 1.

Embodiment 3

[0066] Such as figure 1 and Figure 5 As shown, when it is necessary to verify the ground stress test method in the vertical direction,

[0067] In step 2, the layout of stress main hole 4 and monitoring auxiliary hole 5 is as follows: the number of stress main hole 4 is one, which is set in the center of the side surface of the original rock sample 1 on site, and the number of monitoring auxiliary holes 5 is multiple. The hole 4 is the center and is evenly arranged in a plurality of circles around the main stress hole 4 .

[0068] All the other steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com