Underfill Mining Method with Only Serrated Ore Pillars

A mining method and backfill technology, which are used in underground mining, backfill, surface mining, etc., can solve the problems of difficult recovery, efficient recovery and low recovery rate of the original rock horizontal ore pillar in the later stage, and improve the one-time high-efficiency recovery rate. , the effect of increasing economic benefits and reducing the amount of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

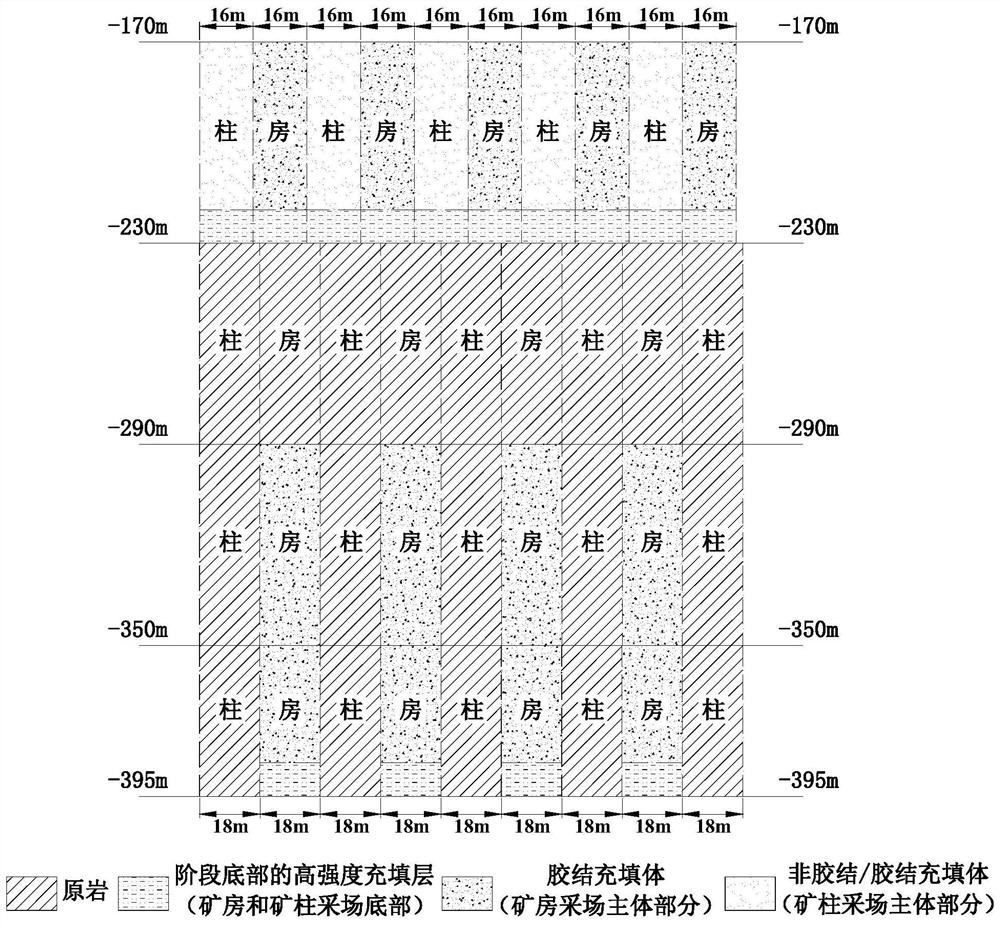

[0062] A large-scale underground iron mine produces about 3 million tons of iron ore per year. The iron grade of the ore is mostly 27-38%, and the highest total iron content is 44.5%. The main ore body is thick, with a thickness of about 40-160m, and the ore body is inclined to steeply, with a dip angle of about 60-80°. The ore rocks and roof and floor of the main ore body are mainly gneiss and amphibolite, with few cracks in the rock mass. The quality of the rock mass is classified as medium, the rock mass is relatively complete, the engineering geological conditions are moderate, and the hydrogeological conditions are moderate.

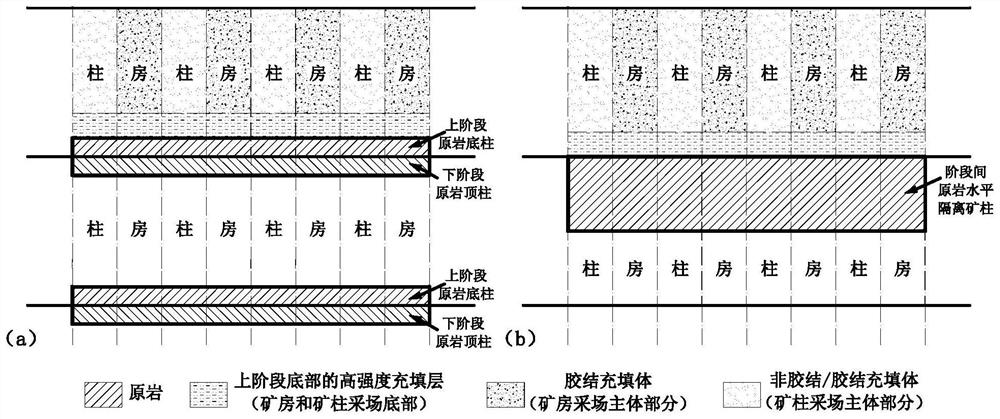

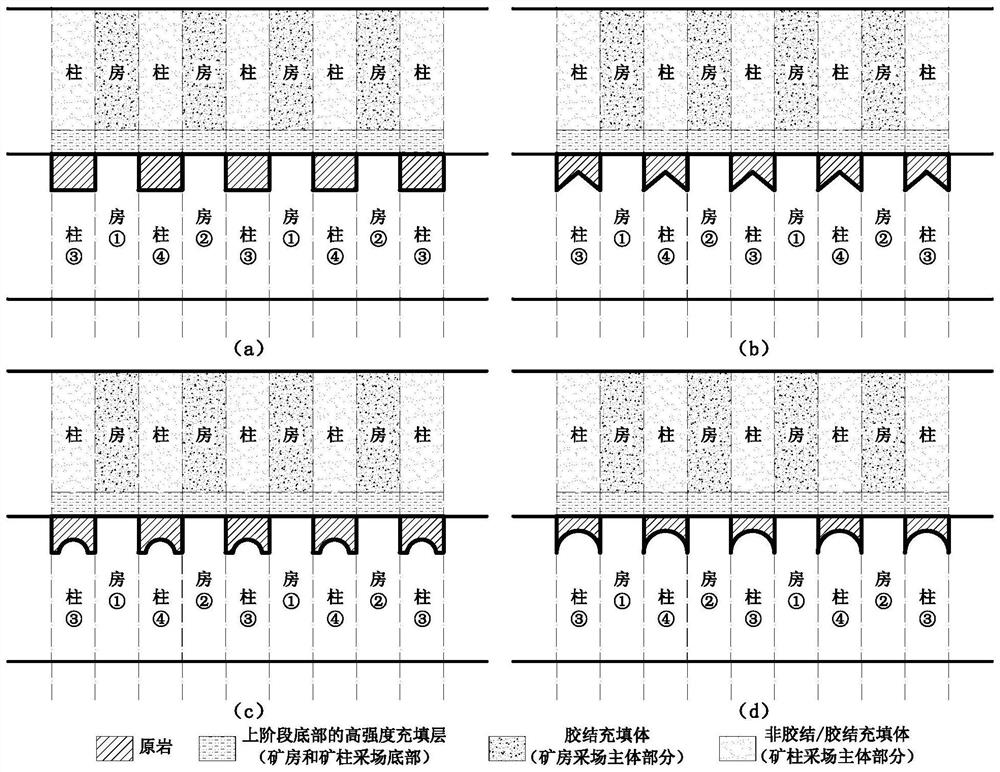

[0063] The design of the main ore body of the mine adopts the large-diameter deep hole stage empty stop and then filling mining method, and the stope is arranged perpendicular to the ore body trend. The height is the stage height, which is 45-60m.

[0064] The main ore body of the mine is currently mainly designed with four mining middle sections (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com