A method for treating phosphate rock tailings using a single positive flotation process

A phosphate ore tailings and positive flotation technology, applied in flotation, solid separation, etc., to achieve the effects of pollution mitigation, high quality concentrate products, and reasonable method design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

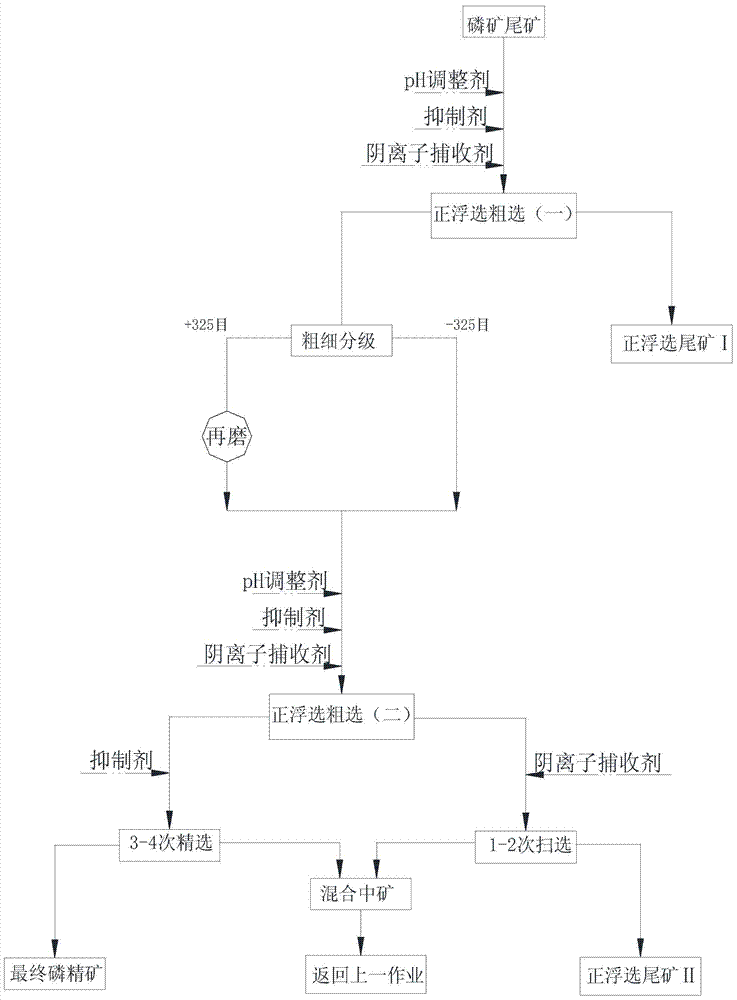

[0016] Embodiment 1, with reference to accompanying drawing, a kind of method that adopts single positive flotation process to process phosphate rock tailings, its steps are as follows:

[0017] (1) Feed the phosphate ore tailings directly into the roughing flotation machine for a roughing, add appropriate amount of pH regulator, inhibitor and anion collector during the roughing, and choose NaCO as the pH regulator 3 , NaOH or lime, water glass and sodium lignosulfonate as the inhibitor, and fatty acid anion collector as the collector;

[0018] (2) The foam product of the roughing operation is classified according to the particle size of 325 mesh; the product of +325 mesh is sent to the grinding operation, and it is ground to the grinding fineness required by the flotation operation;

[0019] (3) The product ground through the ore grinding operation and the -325 purpose product are combined together and given to the secondary roughing operation;

[0020] (4) The foam product ...

Embodiment 2

[0021] Embodiment 2, in the step (1) of a kind of method that adopts single positive flotation process to process collophosite tailings described in embodiment 1, main component contains P by weight percentage in the described phosphate rock tailings 2 o 5 4.0~12.0%, MgO 2.0~18.0%, SiO 2 8.0-30.0%, and a small amount of other impurities.

Embodiment 3

[0022] Embodiment 3, in the step (2) of a method for processing collophosite tailings by a single positive flotation process described in embodiment 1 or 2, the +325 mesh product is given to the grinding operation, and ground to -325 mesh Accounted for 85 to 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com