Method for reducing zinc content of flotation silver concentrates

A silver concentrate and flotation technology, which is applied in the direction of improving process efficiency, can solve the problems of complicated process, many equipments, and decreased zinc recovery rate, and achieve the effects of broad market prospects, good economic benefits, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

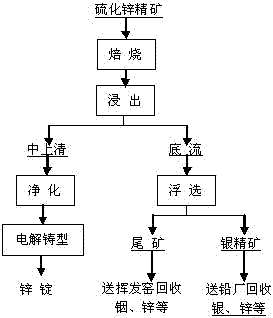

Image

Examples

Embodiment 1

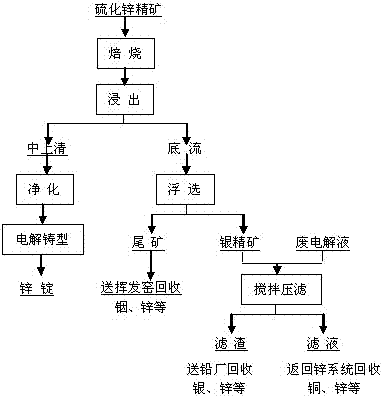

[0015] like figure 2 Shown, a kind of method that reduces flotation silver concentrate containing zinc comprises the following steps:

[0016] The first step: Load 1t of flotation silver concentrate in the concentrate tank, and then pump the waste electrolyte into the concentrate tank through the acid-resistant pump and acid-resistant pipe, where the waste electrolyte contains H 2 SO 4 The concentration is 150g / l, and the amount of waste electrolyte added is 20t.

[0017] Step 2: Start the mixer to make the waste electrolyte and the flotation silver concentrate react while stirring, and the reaction time is 10~30min;

[0018] Step 3: After the stirring reaction is sufficient, press-filter the reacted pulp, send the filter residue to the lead system to recover silver and zinc, and return the filtrate to the zinc system to recover zinc and copper.

Embodiment 2

[0020] A method for reducing the zinc content of flotation silver concentrate, comprising the following steps:

[0021] The first step: Load 1t of flotation silver concentrate in the concentrate tank, and then pump the waste electrolyte into the concentrate tank through the acid-resistant pump and acid-resistant pipe, where the waste electrolyte contains H 2 SO 4 The concentration is 200g / l, and the amount of waste electrolyte added is 15t.

[0022] Step 2: Start the mixer to make the waste electrolyte and the flotation silver concentrate react while stirring, and the reaction time is 10~30min;

[0023] Step 3: After the stirring reaction is sufficient, press-filter the reacted pulp, send the filter residue to the lead system to recover silver and zinc, and return the filtrate to the zinc system to recover zinc and copper.

[0024] Through this process, valuable metals such as zinc and copper in the form of basic salts in the silver concentrate will be leached into the solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com