Beneficiation method for high-sulfur magnetic iron ore of low-grade copper

A technology of magnetite ore and mineral processing methods, applied in chemical instruments and methods, flotation, wet separation, etc., can solve problems such as the lack of perfect copper recovery methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

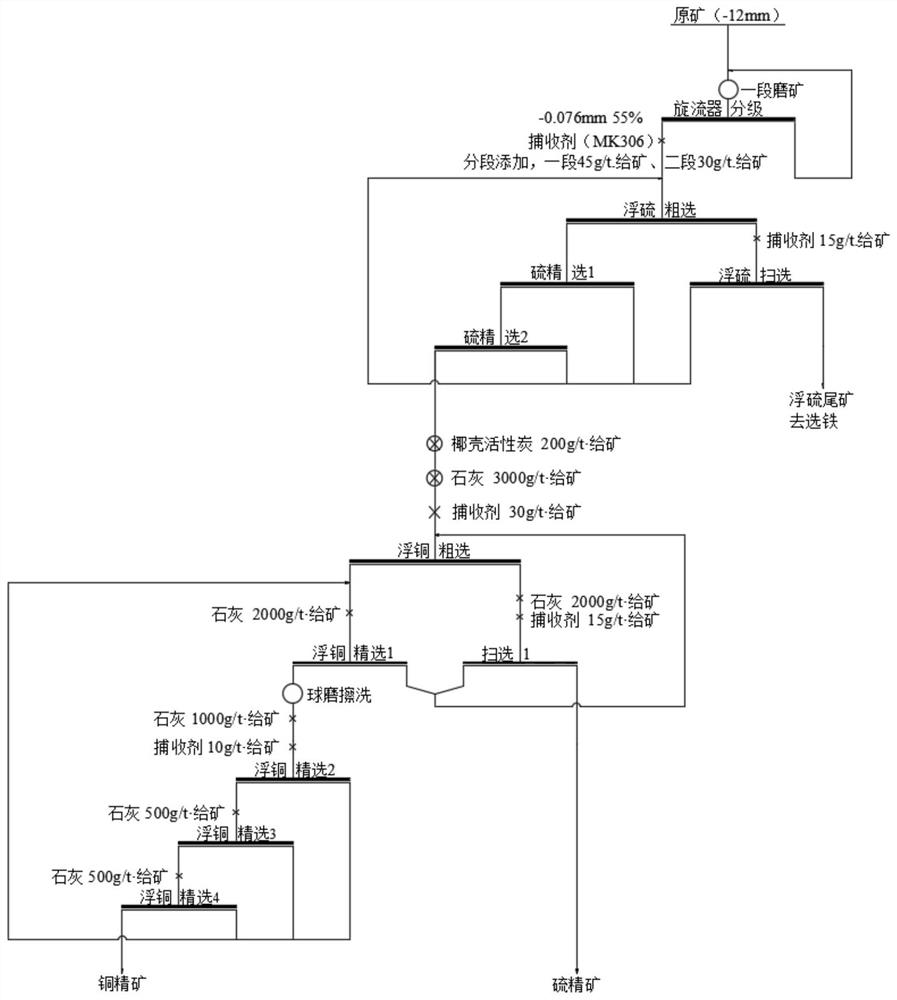

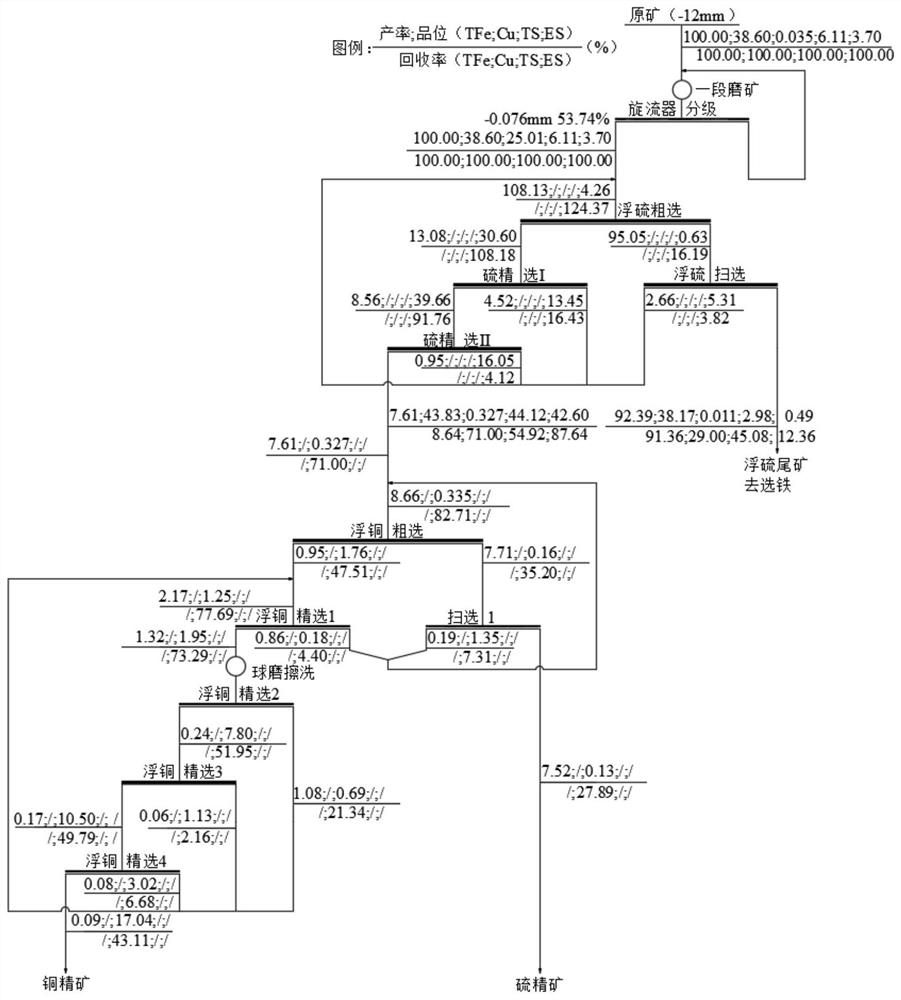

Method used

Image

Examples

Embodiment

[0043] At present, for raw ore with extremely low copper content, it is extremely difficult to comprehensively utilize copper, and it is difficult to generate economic value if the cost is too high. Therefore, the existing beneficiation method is difficult to recycle the copper of the high-sulfur magnetite ore with extremely low copper grade, and the copper grade, enrichment ratio and recovery rate of the final copper concentrate cannot meet the requirements. That is, the cost of actual production is relatively high, and insufficient economic value can be produced. To solve this problem, the present invention provides a beneficiation method capable of obtaining qualified copper concentrate with high economic value. This method is mainly aimed at high-sulfur magnetite ore with a copper grade of 0.02% to 0.05%, and is especially suitable for iron grades of 30%-40%, high-sulfur magnetite ore with a sulfur grade of 3.0%-6.0% and a copper grade of 0.02%-0.05%. The beneficiation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com