Method for manufacturing transparent rock model structure face test piece

A rock model and model structure technology, which is applied in the preparation of test samples, soil material testing, and testing the strength of materials using a stable shear force. It can solve the problems of poor transparency and poor repeatability, and achieve good transparency, High confidence, avoid large discrete effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

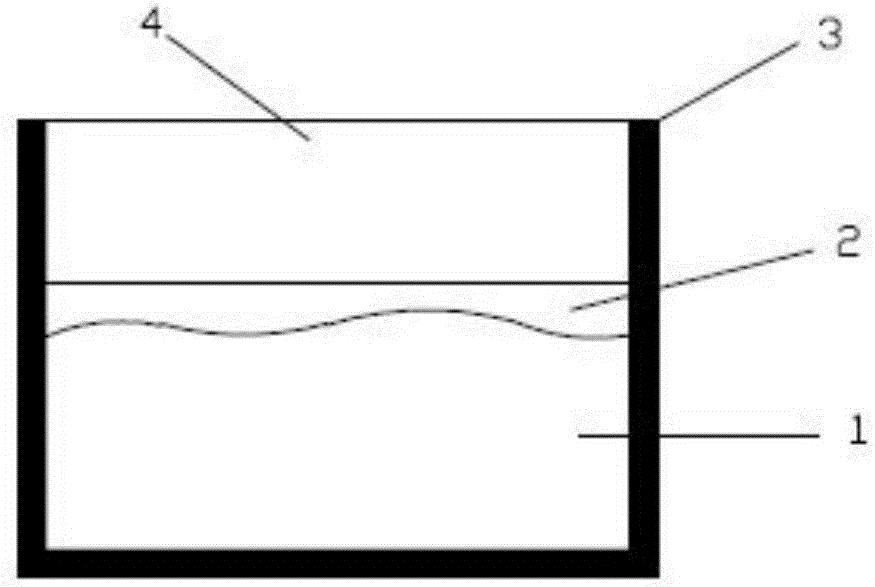

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

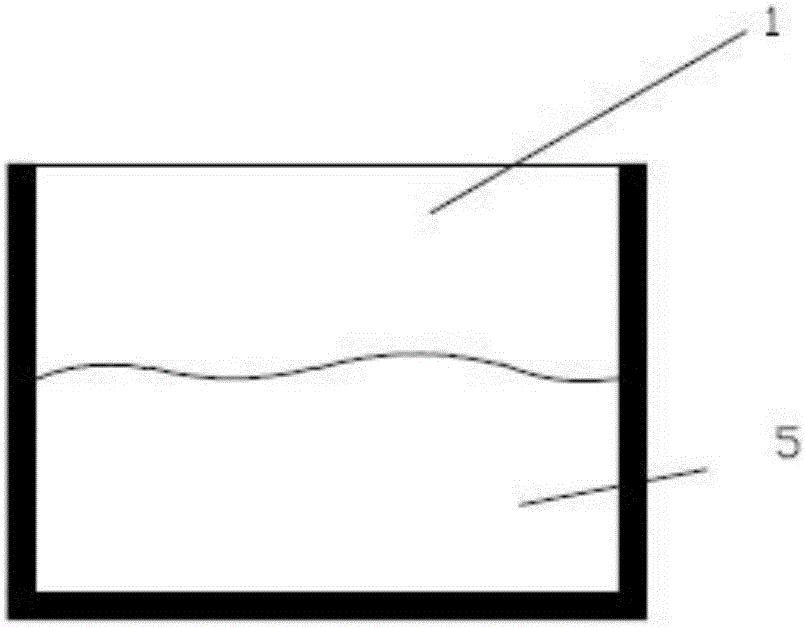

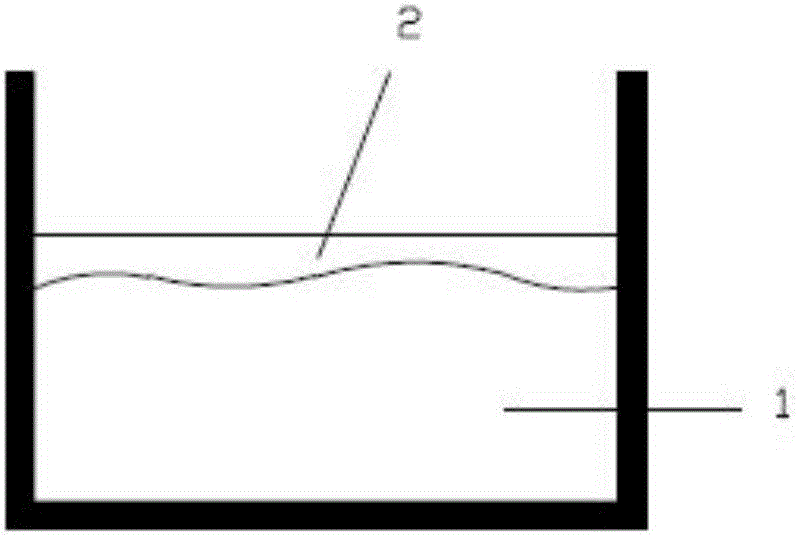

[0029] refer to Figure 1 ~ Figure 3 , a method for making a transparent rock model structure test piece, the method includes the following steps:

[0030] 1) Prepare the structural surface of the original rock: use a coring machine or a stone cutter and a stone mill to process the rock specimen, use different test methods to conduct damage tests on the rock specimen, generate a structural surface in the specimen, and test the structural surface The surface is cleaned to remove debris and cuttings; the different test methods described are the Brazilian split method, the direct shear method and the uniaxial tension method;

[0031] 2) Prepare the stainless steel mold: Customize the mold according to the size of the structural surface of the model, and the left and right opposite sides of the mold can be adjusted and disassembled. Adjust the level of the stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com