Method for removing uranium in gravel-containing protolith loose sand

A sandy, loose technology, applied in the field of contaminated soil remediation, to achieve the effect of large damage, low damage and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]1. Soil collection and preparation: Take 5cm (depth) loose sandy soil samples containing gravel on the surface in different areas in the field, dry and pulverize at 40°C, pass through a sieve with a particle size of 2cm, and then dry at 105-110°C 2-4h, mix evenly, sieve, and ball mill until the particle size of the loose sandy soil containing gravel is 200 mesh (74 μm).

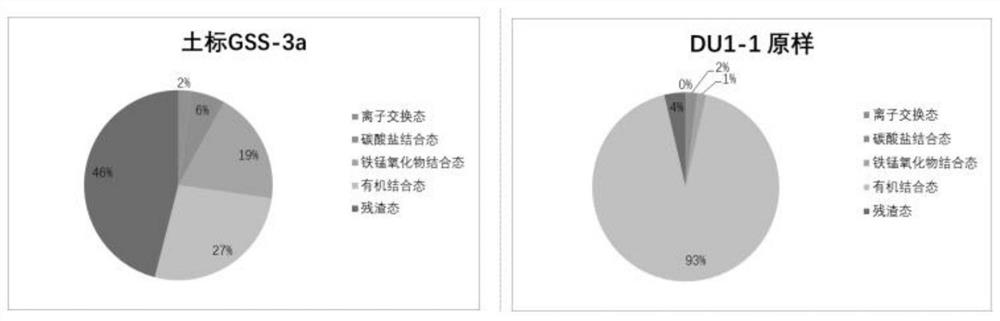

[0036] 2. Extraction of uranium with different binding forms (two parallel samples are set, and the average value is taken):

[0037] 1) Extraction of ion-exchanged uranium: Take 1.5 g of pretreated loose sandy soil containing gravel and put it in a centrifuge tube, and add 30 mL of CH with a concentration of 1 mol / L. 3 COONa solution (extractant), adjust pH to 8, shake at room temperature for 3h, then centrifuge at 9800rpm for 10min with a centrifuge, remove the supernatant, and wash the centrifuge tube twice with 15mL deionized water (pH=7), Pour the washing solution into the original 100mL centrifug...

Embodiment 2

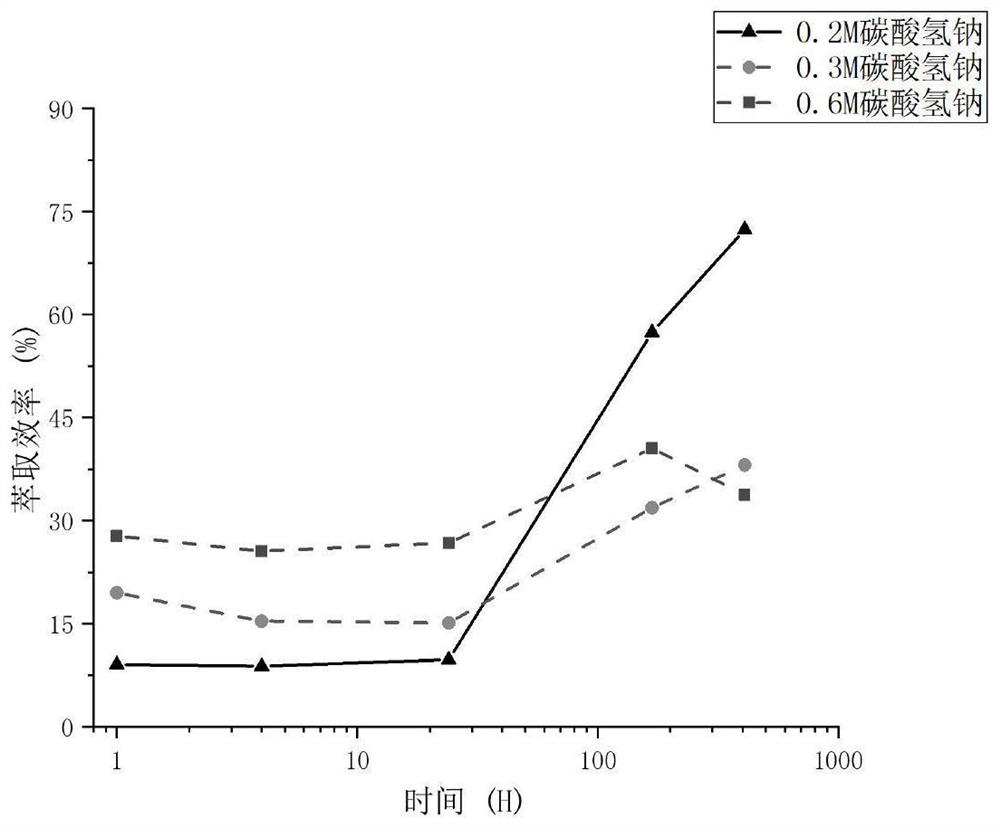

[0048] Using the pretreated sample in Example 1 as the raw material, the leaching test of uranium was carried out. The normal temperature is 25°C.

[0049] The gravel-containing raw rock loose sand, sodium bicarbonate and potassium permanganate were added to a headspace-sealed 50mL flask for the reaction, shaken at 160rpm at room temperature, and the sand and supernatant were separated by centrifugation. The soil was washed twice and combined with the supernatant, filtered with a pinhole syringe equipped with a 0.45 μm filter head, and the filtrate was analyzed by ICP-MS. The residual soil was dried, weighed, and completely dissolved to determine the residual soil uranium concentration.

[0050] The solid-to-liquid ratio described below is the dosage ratio of the leaching solution sodium bicarbonate to the soil sample (loose sandy soil containing original gravel). The soil sample dosage was 3 g.

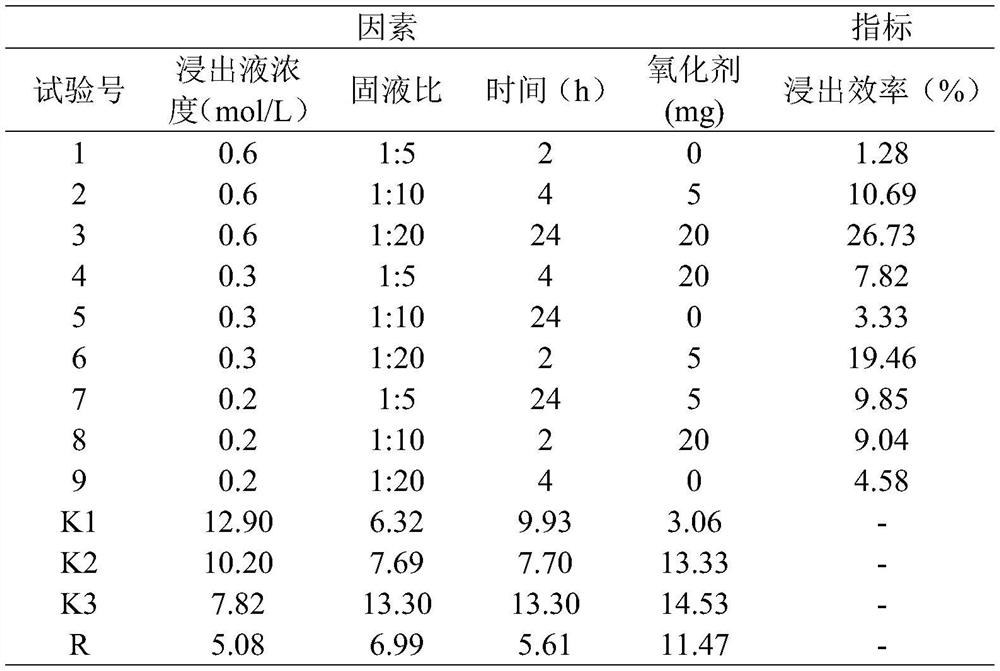

[0051] Four factors and three levels of orthogonal experiments were carried ou...

Embodiment 3

[0060] Same as Example 1, the difference is that the leaching solution sodium bicarbonate is replaced with sodium citrate.

[0061] It was found that the extraction efficiency reached 53.57% after 408 hours. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com