Device for simulating dynamic friction process of protolith and manufacturing method thereof

A technology of dynamic friction and simulation parts, applied in the field of rock dynamic physical and mechanical measurement, can solve the problems of sample secondary processing loss, experimental research is difficult to achieve, dynamic friction description and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with the accompanying drawings, but it is not used to limit the scope of the present invention.

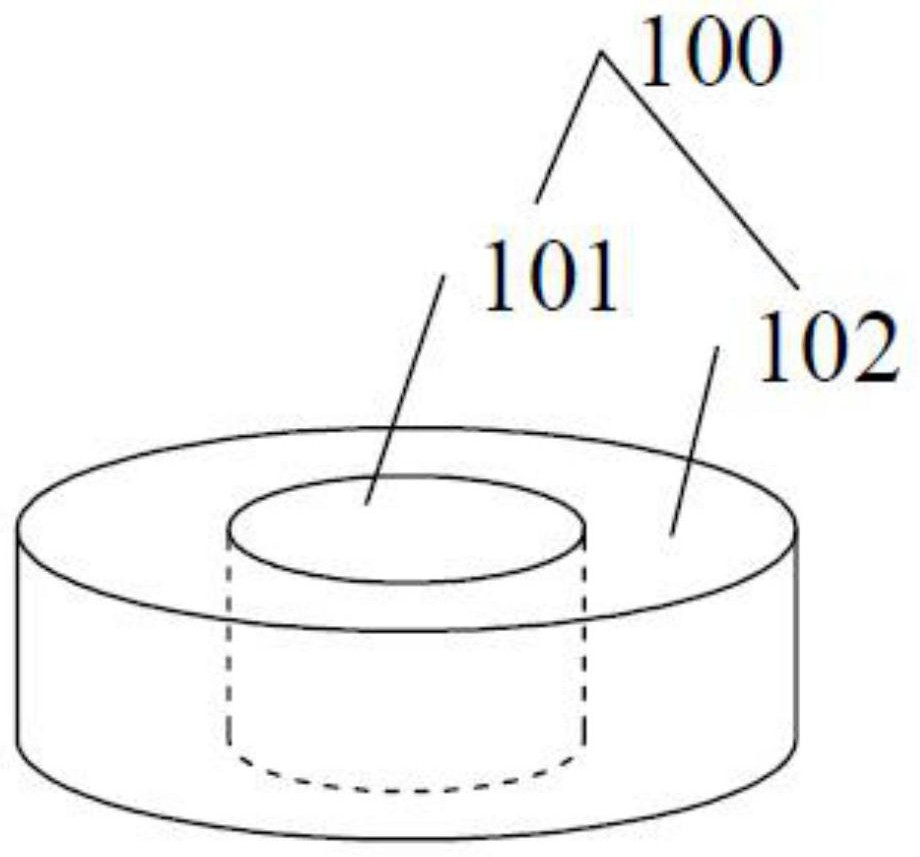

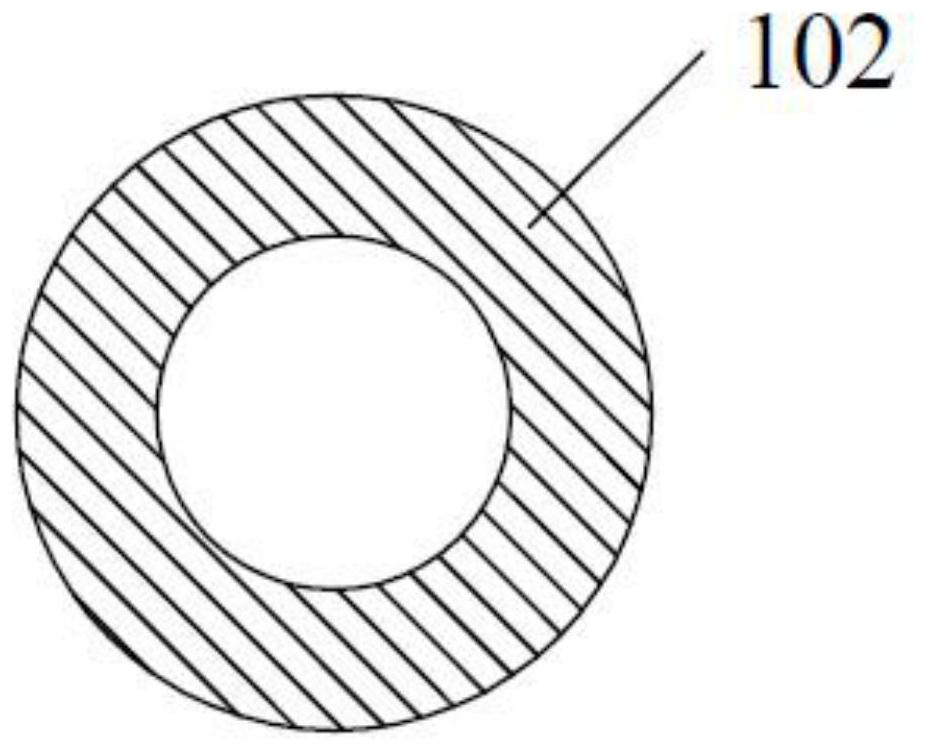

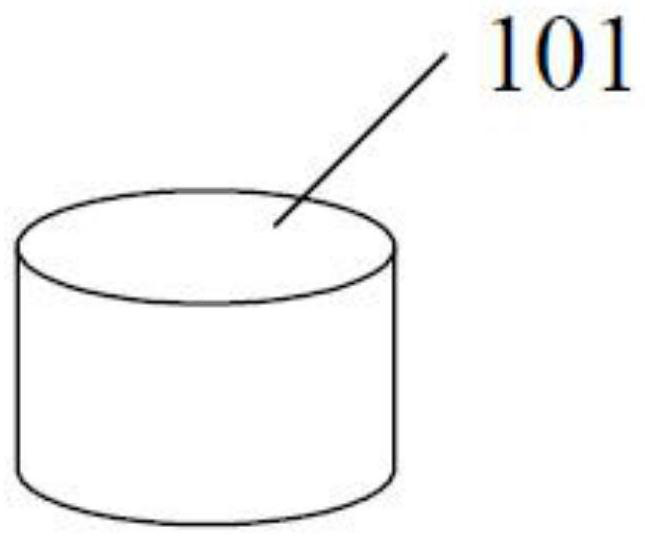

[0028] see Figure 1-4 The device for simulating the dynamic friction process of raw rock provided by the present invention includes a first simulation part 101 for simulating the dynamic friction process of raw rock; a second simulation part 102 for cooperating with the first simulation part 101; The first analog part 101 and the second analog part 102 can be relatively movable and compactly nested, and the nested upper or lower surfaces of the first analog part 101 and the second analog part 102 are flush .

[0029] After simulating the dynamic friction process of the original rock, the first simulation part and the second simulation part are separated from each other, and the first simulation part and the second simulation part can be reset and nested together by manual reset, And the upper surface and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com