Sandstone similar material and preparation method thereof

A technology of similar materials and sandstone, applied in the field of preparation of rock-like material specimens, to achieve the effects of wide practicability, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Present embodiment provides a kind of sandstone similar material formula:

[0028] The aggregate is quartz sand (50 mesh) and silica fume (350 mesh), the cement material is cement, and the additives are water reducer and distilled water. Wherein in parts by weight, cement: quartz sand: silica fume: distilled water: water reducing agent=20:16:2.2:5.6:0.2.

[0029] The present embodiment provides the preparation method of this similar material, and the operation steps are as follows:

[0030] a. Weigh cement, quartz sand and silica fume, mix and stir evenly to obtain mixed powder a;

[0031] b. Weigh distilled water and water reducer and mix well to obtain mixed solution b;

[0032] c. Add the mixed powder material a into the mixed liquid material b, and use a high-strength mixer to fully stir evenly;

[0033] d. Pour the mixed materials into the pre-made mold, pay attention to control the pouring speed, at 30-40m 3 Slow and uniform pouring at a speed of / h;

[0034]...

Embodiment 2

[0038] A sandstone-like material in this embodiment includes coarse aggregate quartz sand, fine aggregate silica powder, cement cement, additive polycarboxylate water reducer, and distilled water, wherein the components are calculated in parts by weight, cement: quartz sand : silicon powder: distilled water: water reducer = 16:18:3.2:5.2:0.25.

[0039] Its preparation method is similar to that of Example 1 and will not be repeated here.

Embodiment 3

[0041] A sandstone-like material in this embodiment includes coarse aggregate quartz sand, fine aggregate silica powder, cement cement, additive polycarboxylate water reducer, and distilled water, wherein the components are calculated in parts by weight, cement: quartz sand : silicon powder: distilled water: water reducer = 20:14:1.8:5:0.15.

[0042] Its preparation method is similar to that of Example 1 and will not be repeated here.

[0043] The development of similar materials must first select suitable similar materials, suitable preparation methods and maintenance methods, and then calculate the similarity ratio according to the similarity theory and the physical and mechanical properties of the original rock in actual engineering, so as to determine the physical and mechanical parameters of similar materials, and finally prepare the Similar materials for research purposes.

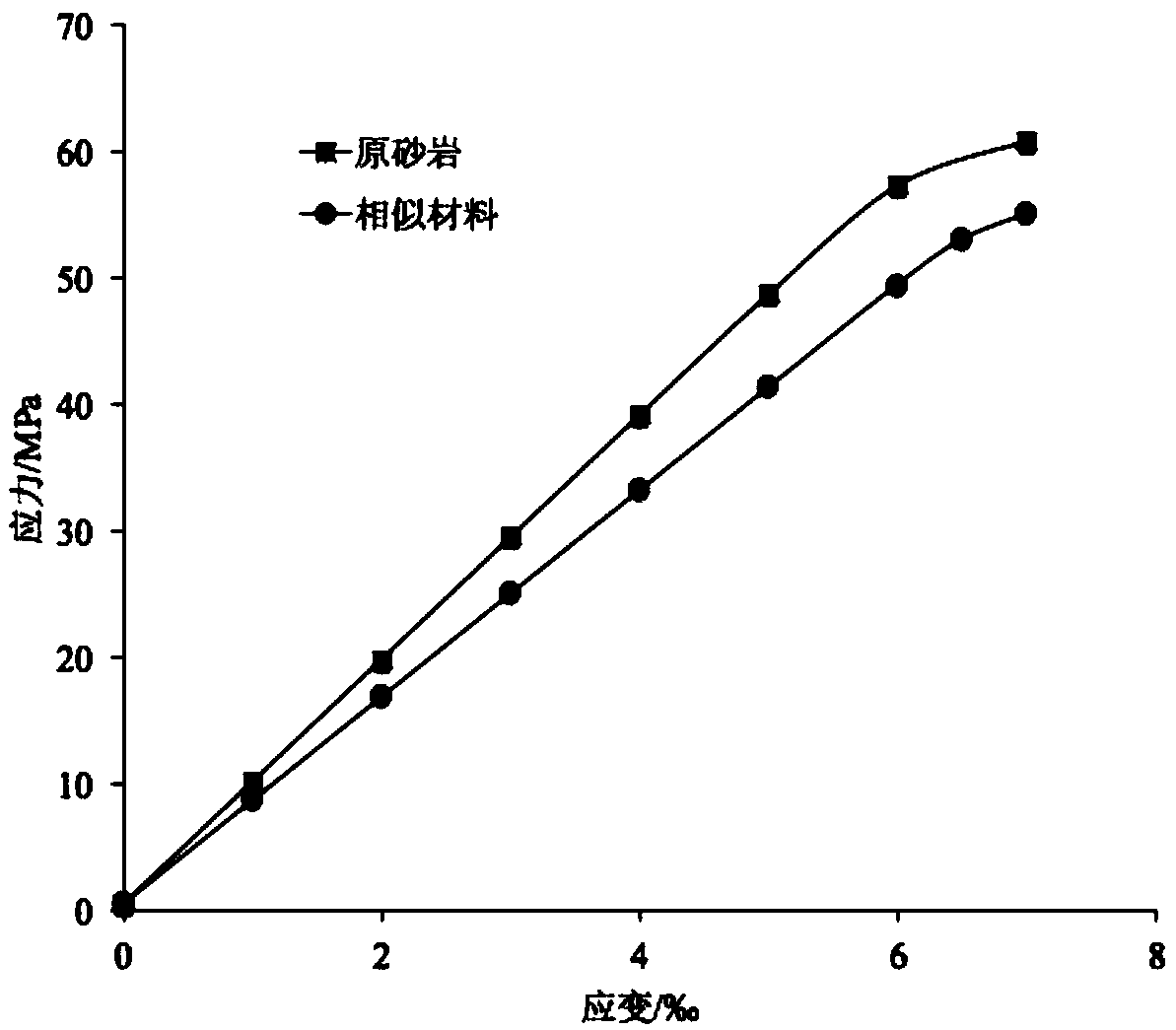

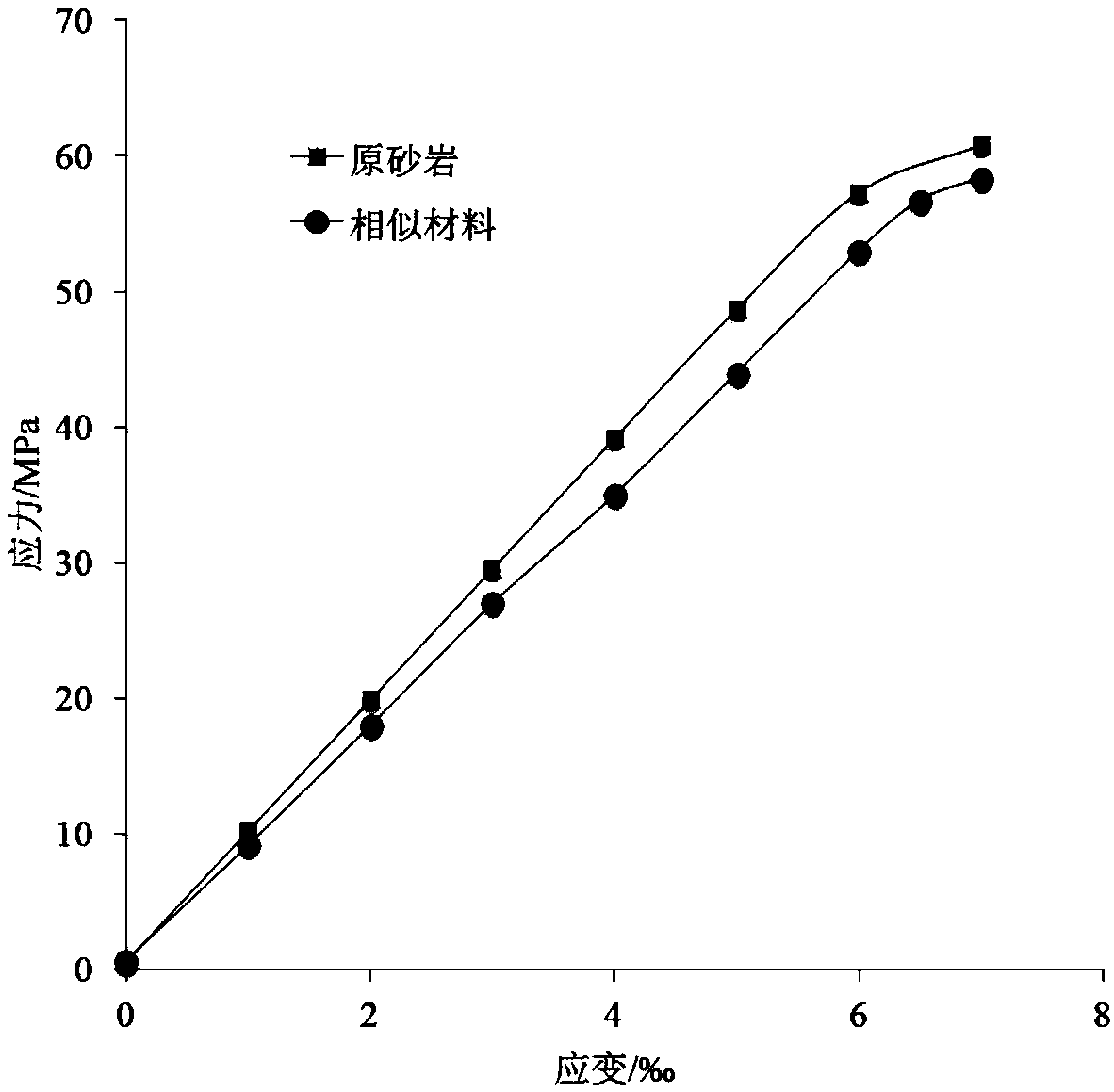

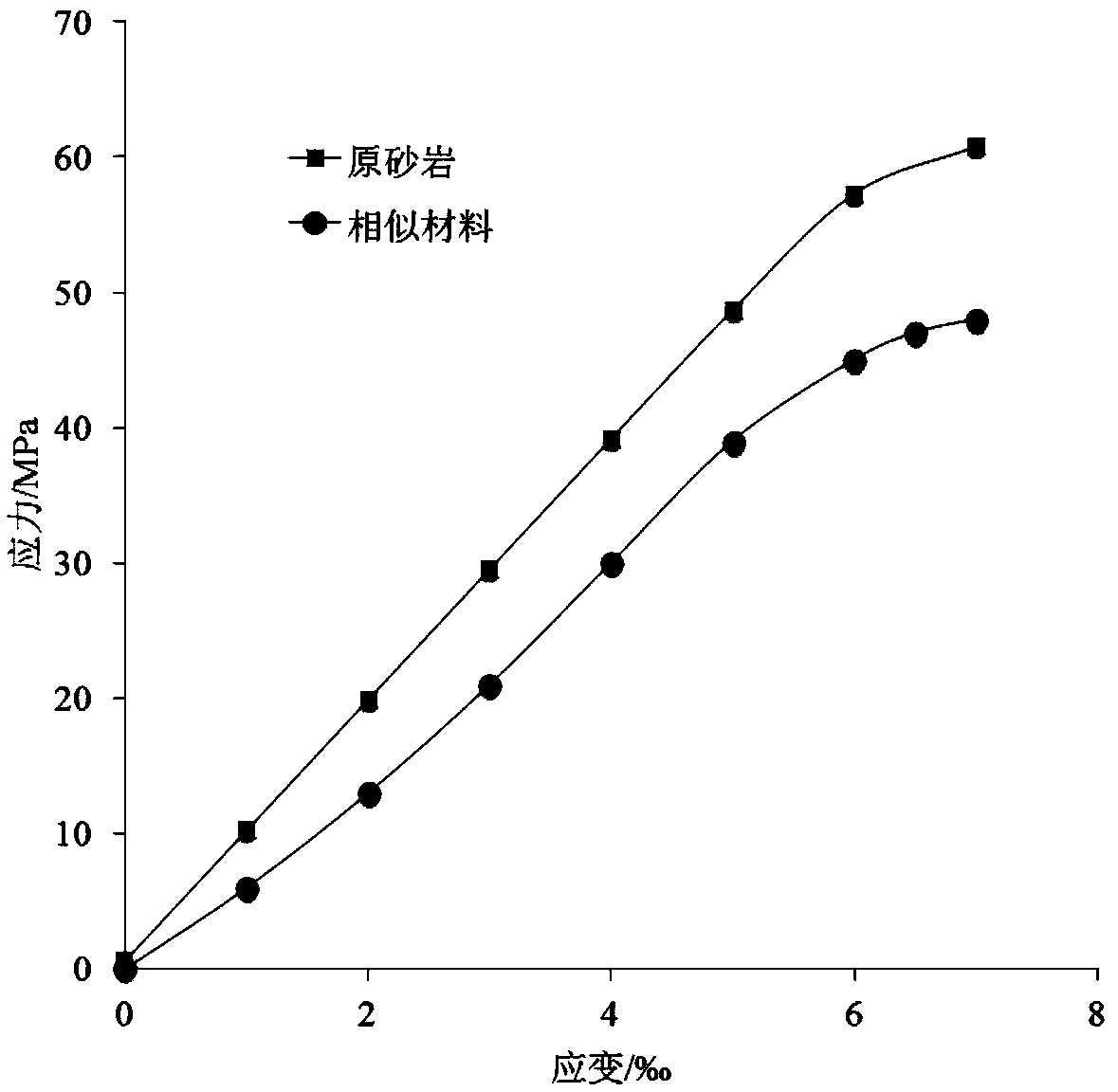

[0044] Table 1 has listed the sandstone similar material that the embodiment of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com