Efficient sampling device of organic-matter-rich mudstone section

A technology rich in organic matter and sampling device, applied in sampling device, sampling, measuring device and other directions, can solve the problems such as the shaft sleeve and the sample cannot be completely matched, the cylindrical sample is not standard enough, and the accuracy of the experimental data is affected, so as to save grinding Steps, improve stability, improve the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

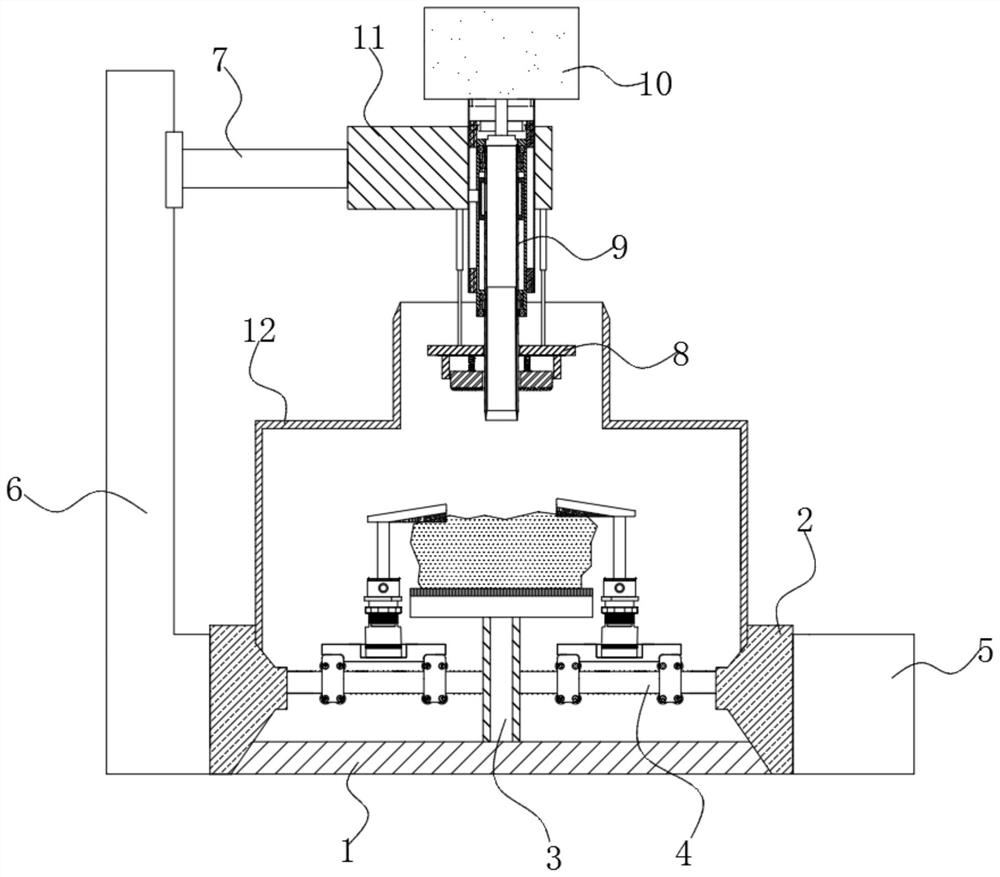

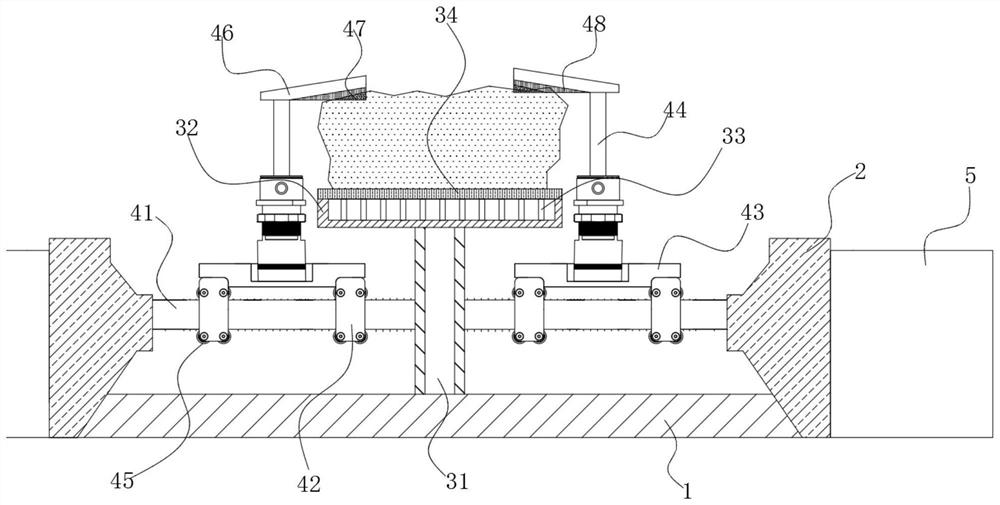

[0032] see Figure 1~4 , in an embodiment of the present invention, a high-efficiency sampling device for organic-rich mudstone section, which includes a base 1, a ring pedestal 2, a sample placement assembly 3, a support arm 6 and a connecting arm 7, wherein the middle part of the base 1 is provided with a The sample placement component 3 is used to place the original rock sample to be sampled. The base 1 is also fixed with a ring pedestal 2, and one side of the ring pedestal 2 is fixed with a support arm 6, which can be moved up and down. The moving connection has the connecting arm 7, specifically, the supporting arm 6 can use the screw nut pair structure to drive the connecting arm 7 slidingly connected with it to slide up and down;

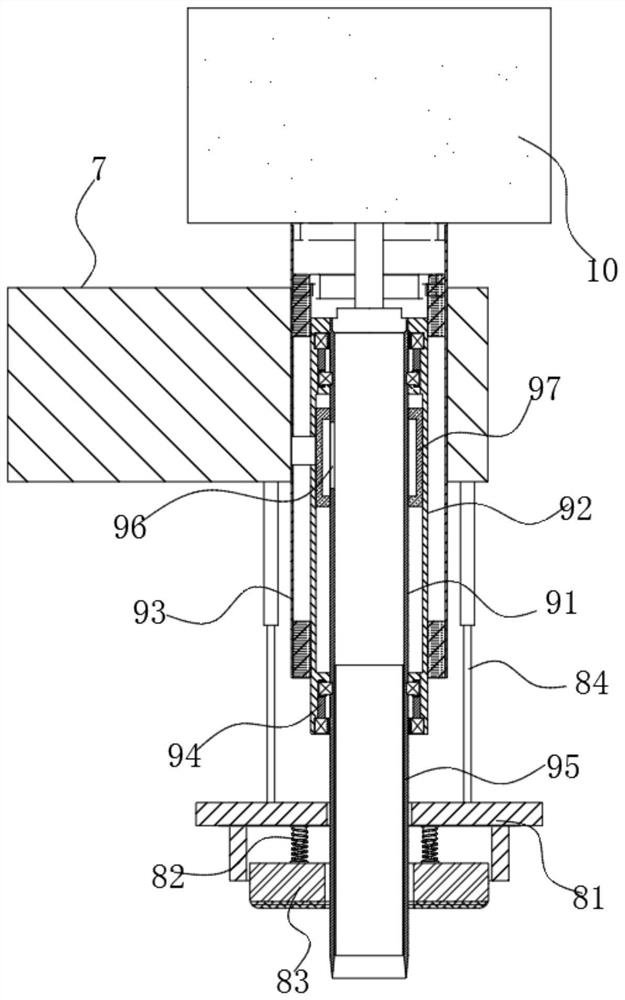

[0033] The other end of the connecting arm 7 adopts a mounting seat 11 to be provided with a sampling assembly 9, the sampling end of the sampling assembly 9 is cylindrical, and by driving the sampling end to rotate, a columnar sample can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com