Protolith structural plane sample manufacturing device and manufacturing method

A technology for manufacturing devices and structural surfaces, which is applied in the field of sample manufacturing devices for structural surfaces of original rocks, to achieve the effect of facilitating the normal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

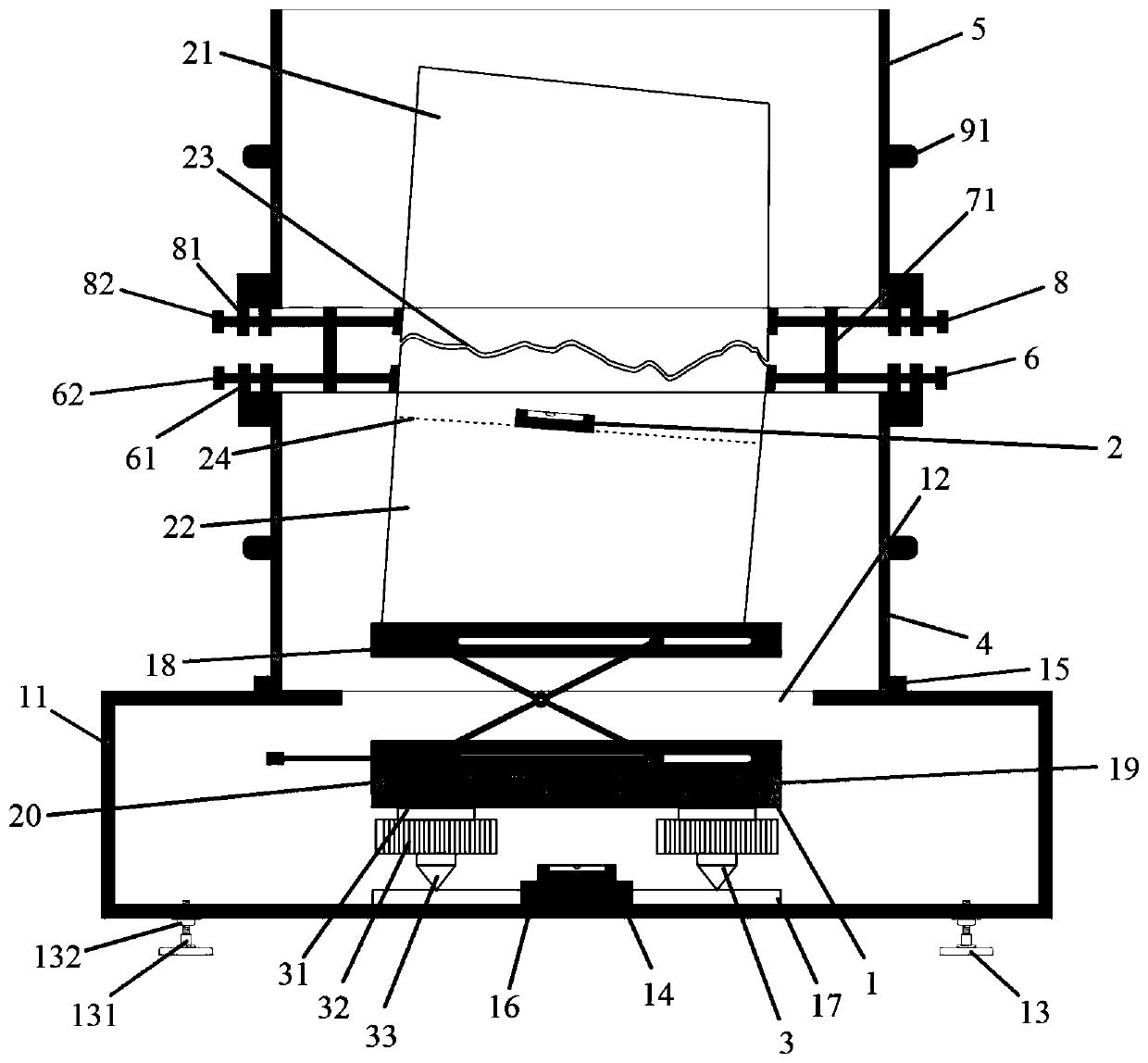

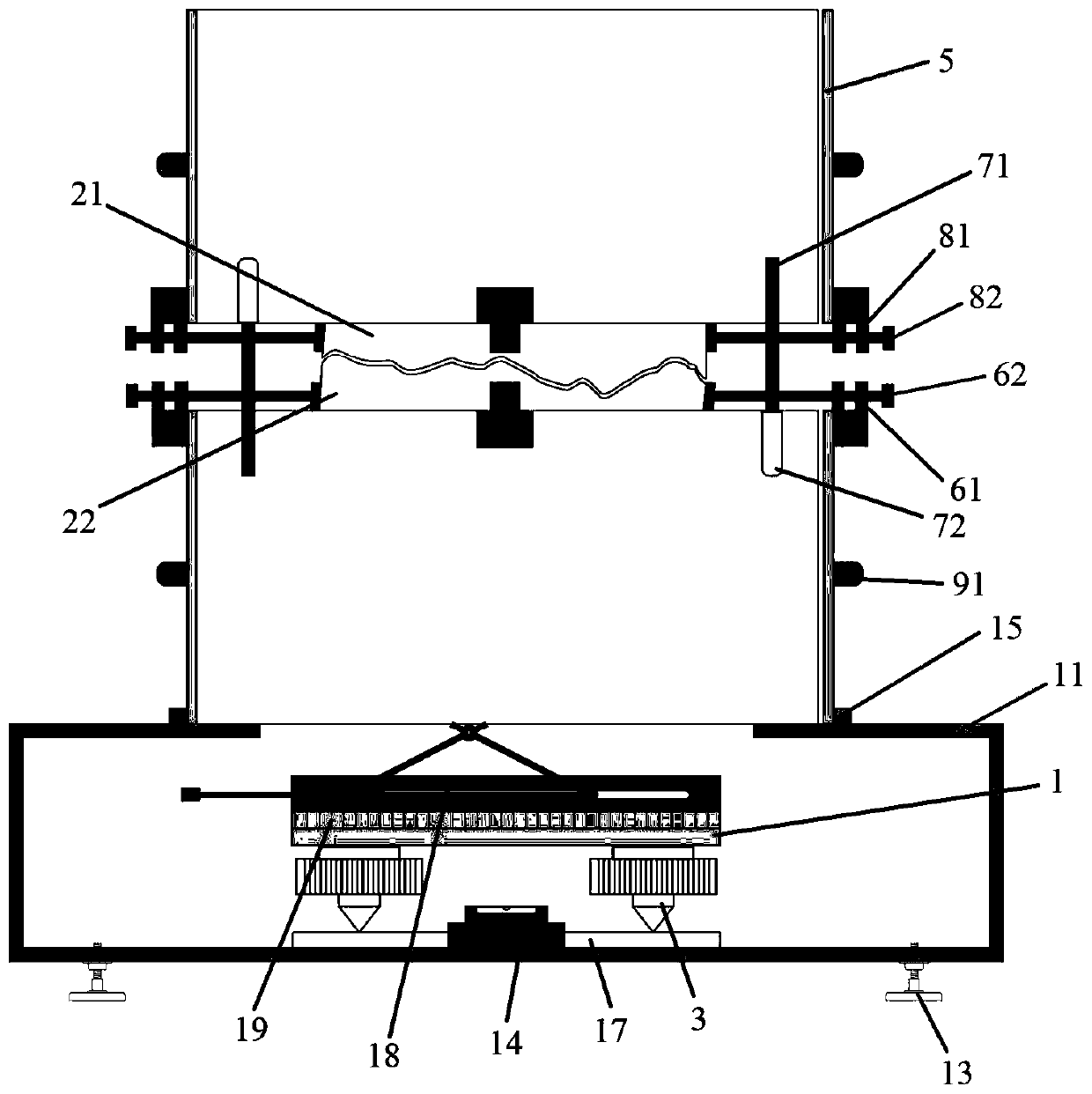

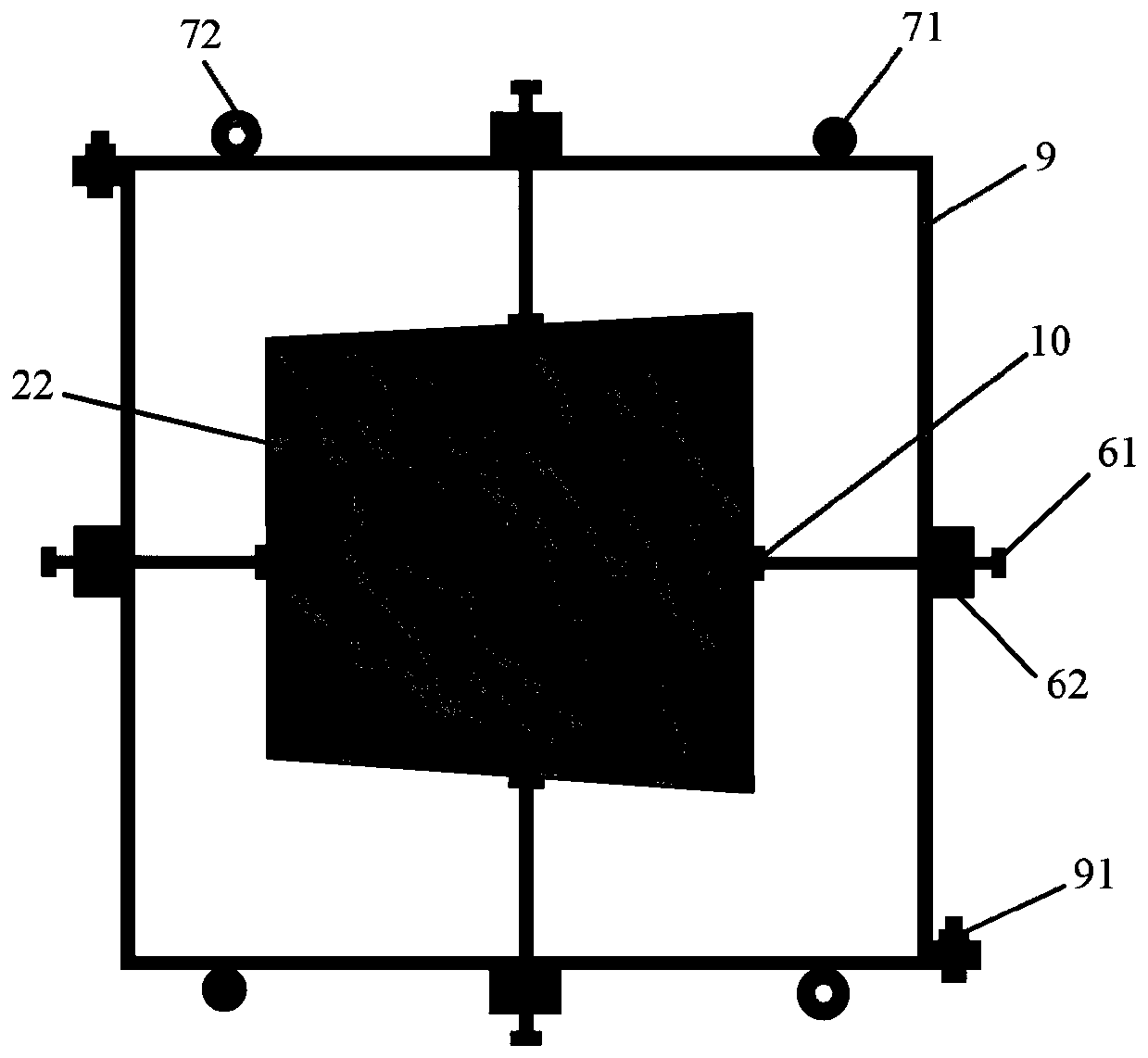

[0035] See Figure 1 to Figure 4 , the embodiment of the present invention provides a kind of proto-rock structural surface sample production device, comprises bearing table 1, first level gauge 2, a plurality of first height adjustment parts 3, lower plate mold 4, upper plate mold 5, lower fixing member 6. A plurality of supporting components 7 and an upper fixing member 8 .

[0036]The bearing platform 1 is used to carry the lower wall 22 of the structural surface, the first level 2 is used to be installed on the side wall of the lower wall 22 of the structural surface, and is parallel to the fitting plane of the structural surface 23 of the original rock. The first height adjusting member 3 is fixedly installed at the bottom of the carrying platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com