Non-closed borehole sealing process and structure

An unsealed and crafted technology, applied in sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve problems such as hidden water inrush in mine pits, unknown drilling actual trajectory, and inability to determine the actual location of drilling, etc. To achieve the effect of avoiding local lack of pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

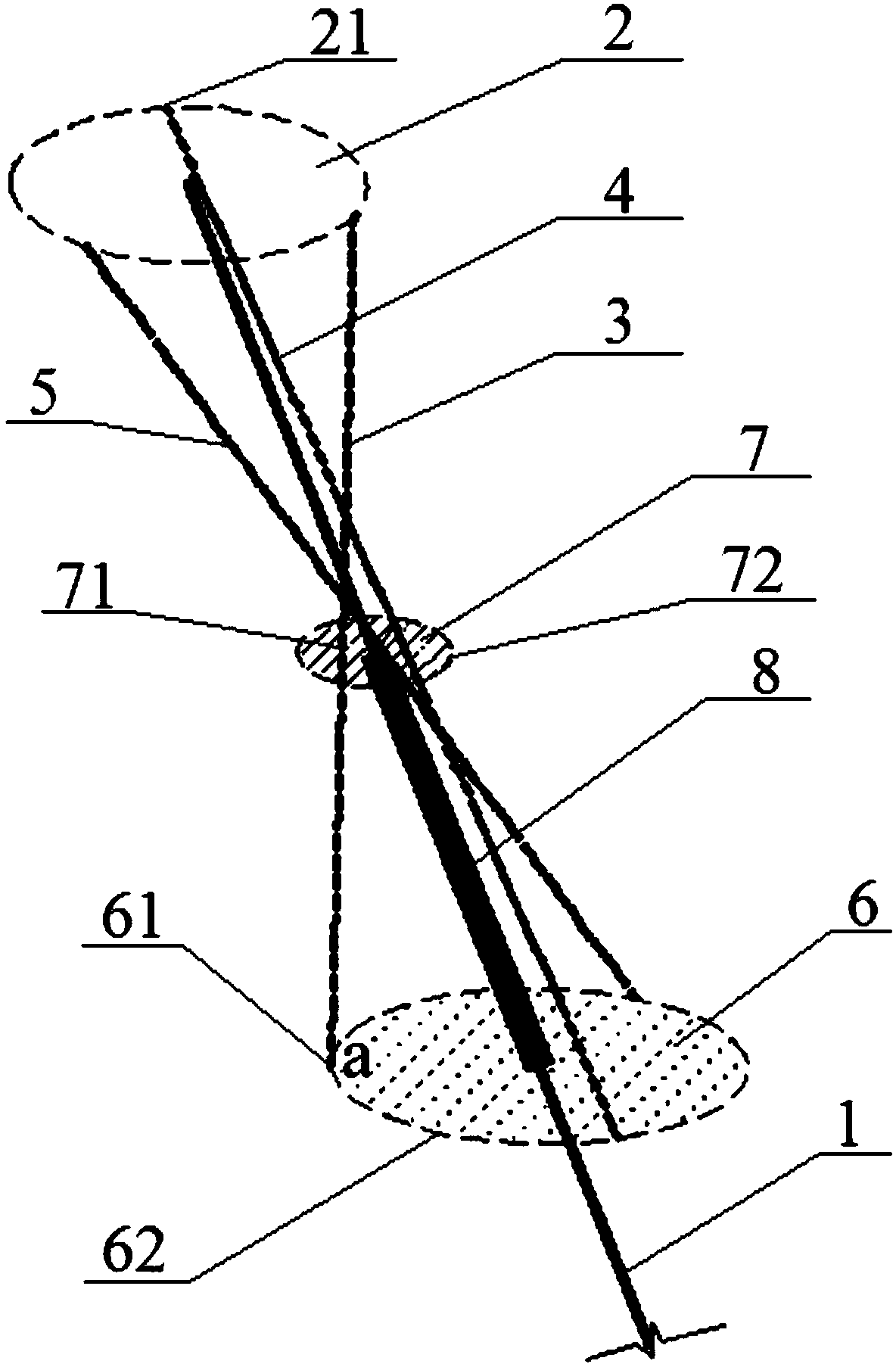

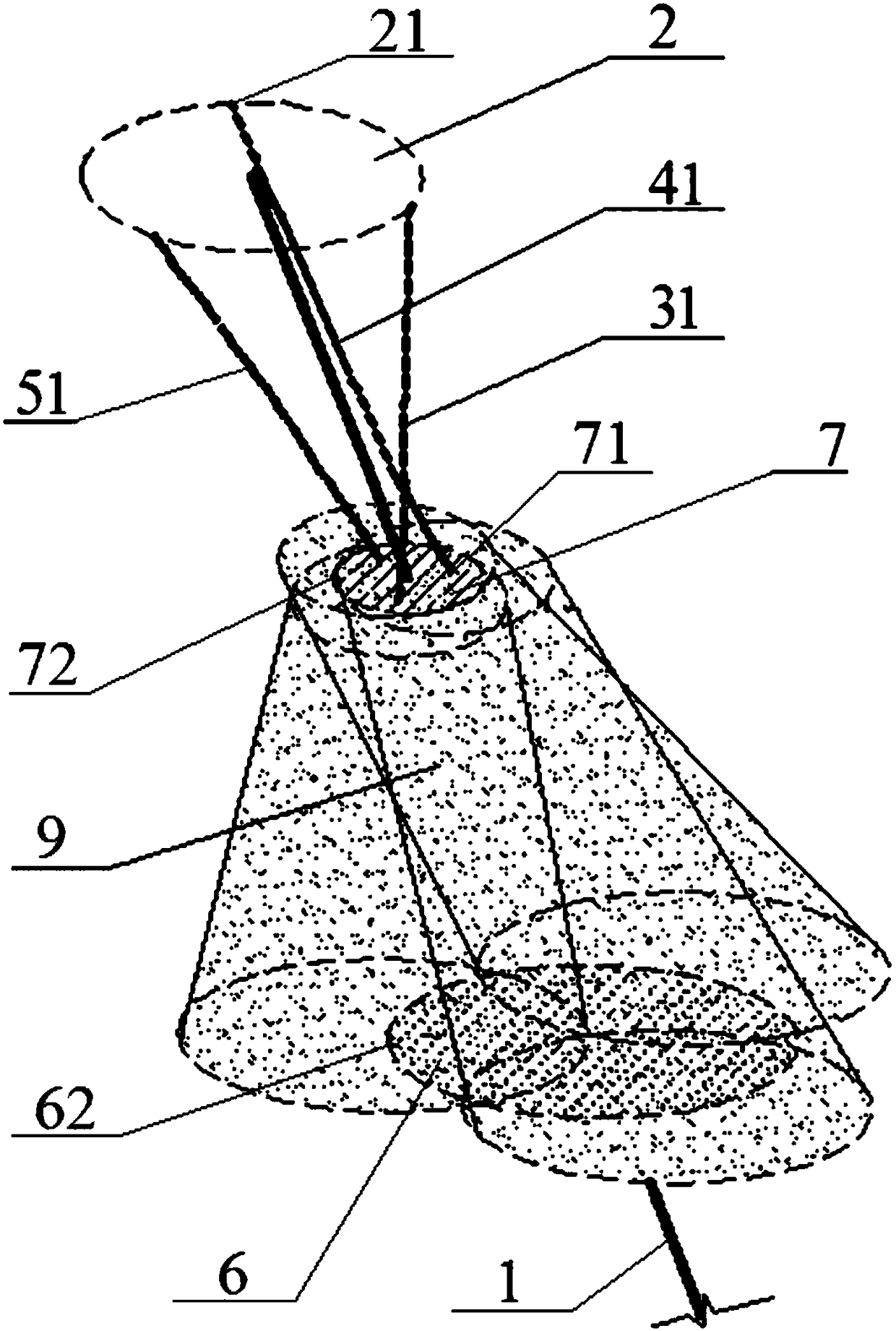

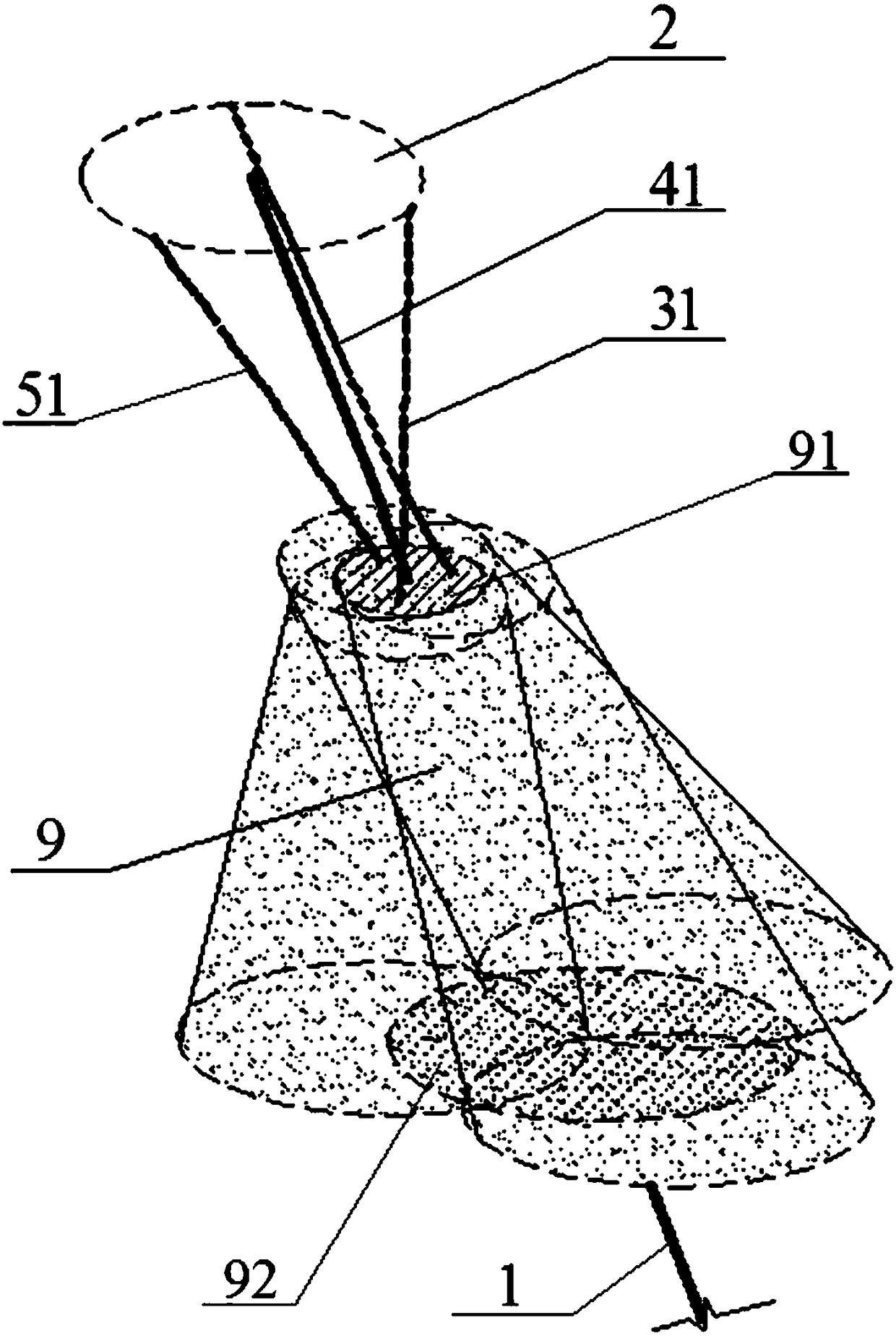

[0040] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0041] In the embodiment of the present invention, the unsealed borehole plugging process is applied to a mining area in a certain area. The mining area in this area is located at the top of a channel alluvial fan, covered with thick Quaternary strata, with a total thickness of 50m to 180m . The Quaternary formation is highly permeable and water-rich, consisting of thick gravel, pebbles, sand and discontinuous cohesive soil layers, and is closely related to the hydraulics of the channel, forming a thick Quaternary strong water body.

[0042] During the geological survey of iron mines in the 1970s in this mining area, there were 18 old boreholes that were not sealed after the final hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com