Method for preparing nanometer graphene materials in large scale mode through hydraulic shearing

A nano-graphene and hydraulic shearing technology, applied in the field of nano-materials, can solve problems such as uniformity and inability to prepare sizes, and achieve the effects of not being easy to agglomerate, realizing large-scale continuous production, and uniform sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

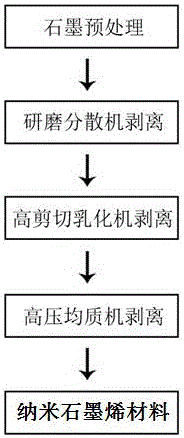

Image

Examples

Embodiment 1

[0030] Take 5g of potassium ferrate, dissolve it in 1L of deionized water, then weigh 50g of graphite powder, and preliminarily mix it with the potassium ferrate solution under magnetic stirring to obtain a graphite mixed solution;

[0031] will step The graphite mixture in the mixture is injected into the grinding and dispersing machine for the first mechanical peeling, the rotating speed is 500rpm, and the grinding time is 2h; the graphene suspension with larger particle size is obtained;

[0032] will step The graphene suspension prepared by the first mechanical exfoliation in the process is directly sent into the high-shear emulsifier through a pipeline, and mechanically exfoliated and dispersed for 0.5h under a shear force of 2000ips to obtain graphite with a smaller size and more uniform dispersion. olefin dispersion;

[0033] will step After the second mechanical stripping and mixing, the graphene dispersion is directly sent to the high-pressure homogenize...

Embodiment 2

[0037] Weigh 10g potassium ferrate, dissolve it in 1L deionized water, then weigh 50g graphite powder, and preliminarily mix it with potassium ferrate solution under magnetic stirring to obtain graphite mixed solution;

[0038] will step The graphite mixture in the mixture is injected into the grinding and dispersing machine for the first mechanical peeling, the rotating speed is 500rpm, and the grinding time is 2h; the graphene suspension with larger particle size is obtained;

[0039] will step The graphene suspension prepared by the first mechanical exfoliation in the process is directly sent into the high-shear emulsifier through a pipeline, and mechanically exfoliated and dispersed for 0.5h under a shear force of 2000ips to obtain graphite with a smaller size and more uniform dispersion. olefin dispersion;

[0040] will step After the second mechanical stripping and mixing, the graphene dispersion is directly sent to the high-pressure homogenizer through the ...

Embodiment 3

[0044] Weigh 10g potassium ferrate, dissolve it in 1L deionized water, then weigh 50g graphite powder, and preliminarily mix it with potassium ferrate solution under magnetic stirring to obtain graphite mixed solution;

[0045] will step The graphite mixed solution in the mixture is injected into the grinding and dispersing machine for the first mechanical peeling, the rotating speed is 1000rpm, and the grinding time is 2h; the graphene suspension with larger particle size is obtained;

[0046] will step The graphene suspension prepared by the first mechanical exfoliation in the process is directly sent into the high-shear emulsifier through a pipeline, and mechanically exfoliated and dispersed for 0.5h under a shear force of 2000ips to obtain graphite with a smaller size and more uniform dispersion. olefin dispersion;

[0047] will step After the second mechanical stripping and mixing, the graphene dispersion is directly sent to the high-pressure homogenizer thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com