Large-size experimental model preparation device and method based on geotechnical materials

A technology for preparing devices and experimental models, applied in teaching models, educational appliances, instruments, etc., can solve problems such as low similarity of batch models, large errors, and damage to stress states.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

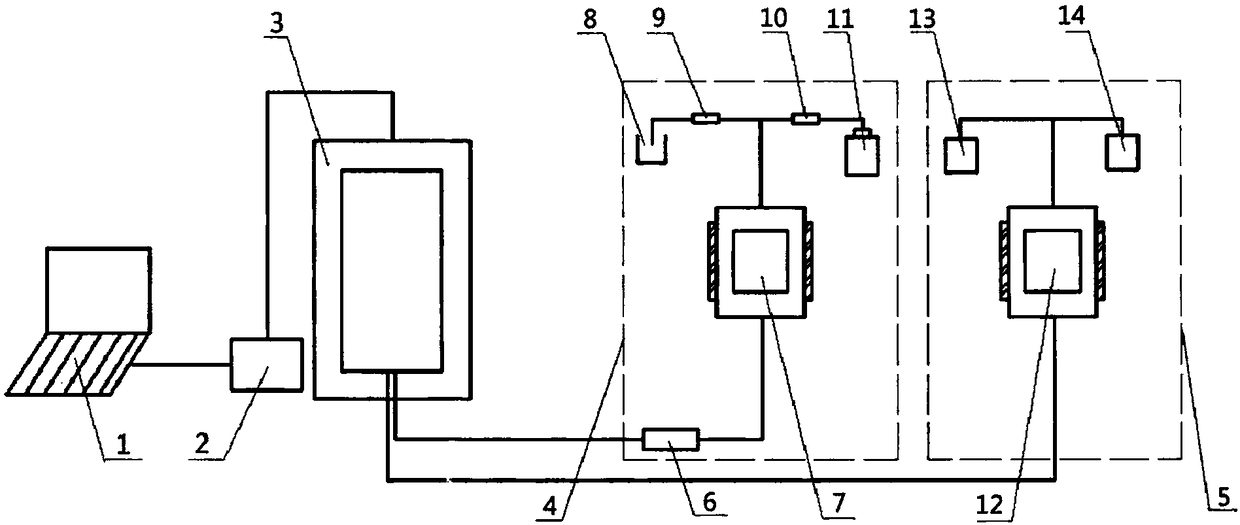

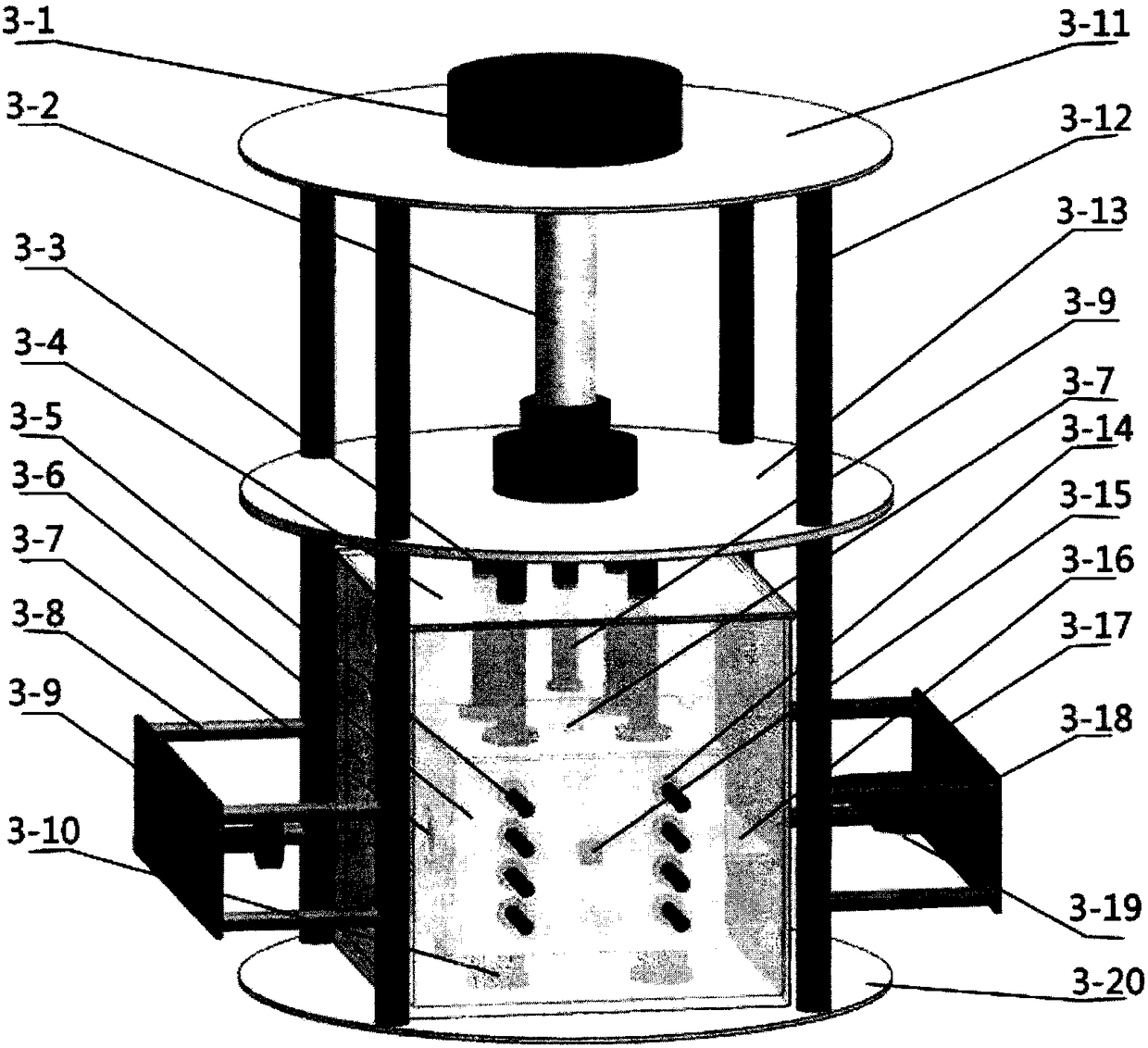

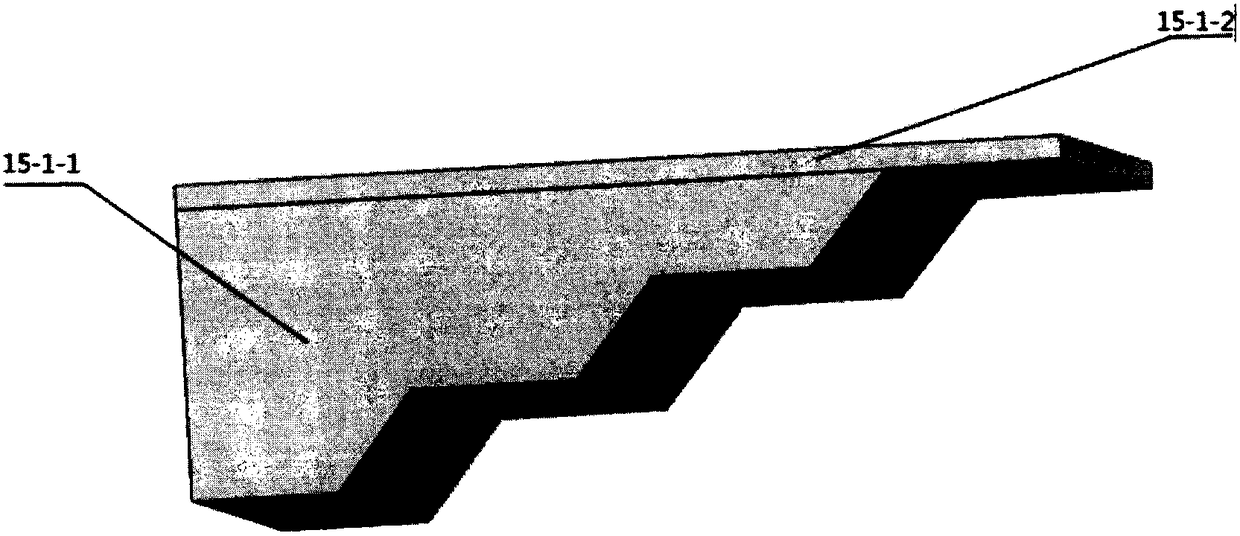

[0028]The embodiment of the present application provides a large-scale experimental model preparation device and method based on geotechnical materials, so as to solve the problem that the model size of the device in the prior art is small, cannot include bedding and other sedimentary structures, and the similarity between different batches of models is low , large errors, and technical problems that cannot be formed at one time; the controllable simulation state of the enlarged simulation device has been achieved, the entire production process can be formed at one time, and follow-up experiments can be carried out without subsequent processing, which greatly improves the efficiency of indoor model experiments. The temperature and pressure of the process are all controlled by computer without manual participation, reducing errors, ensuring the similarity of each batch of models, and providing high-similarity experimental materials for subsequent indoor model experiments in geote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com