Method and device for ground stress testing reproducing wave velocity

A technology of ground stress and wave velocity, applied in the field of geophysical exploration, can solve problems such as difficult measurement, fitting calculation, constitutive model establishment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the present invention will be further described in conjunction with the accompanying drawings.

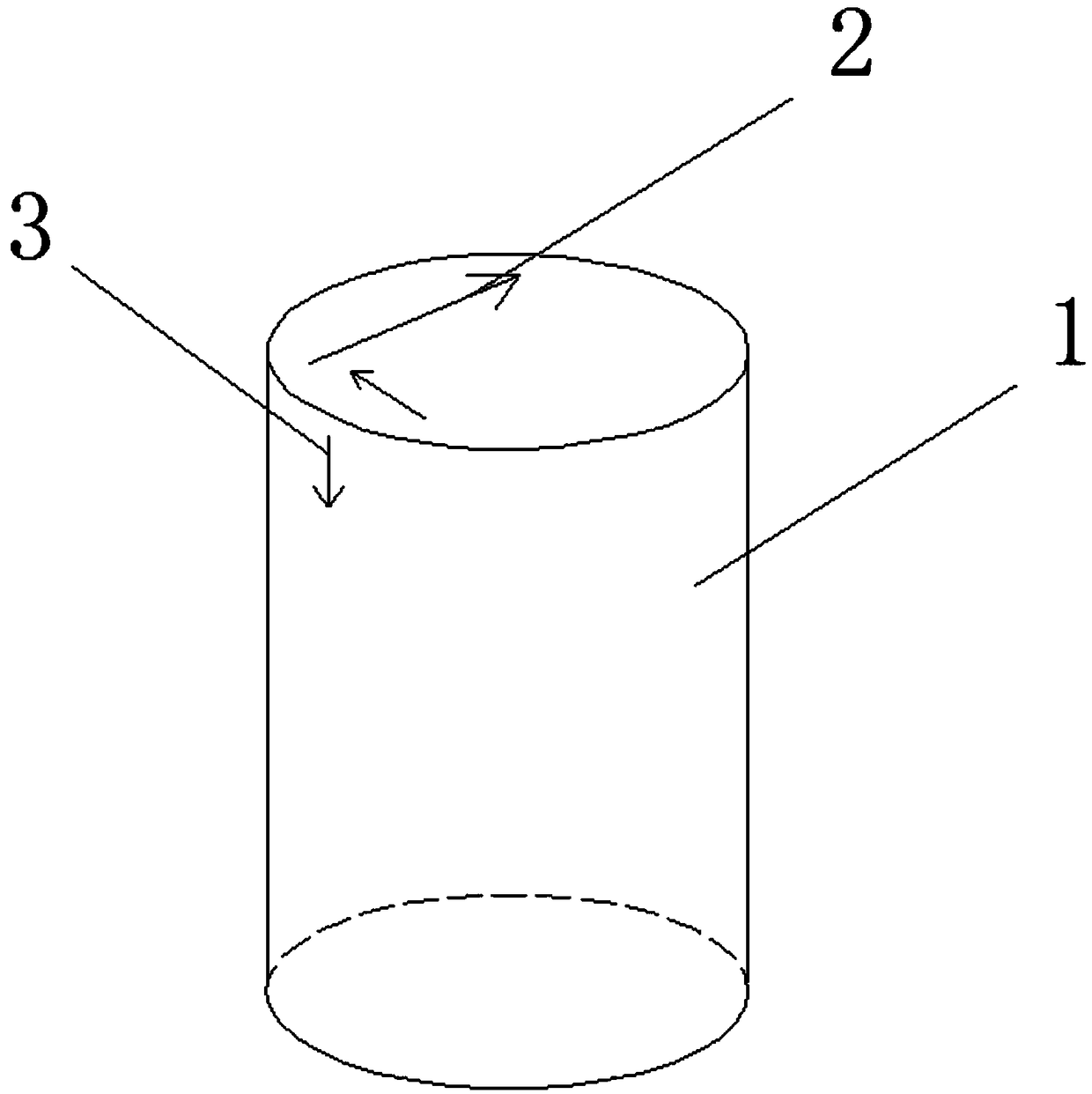

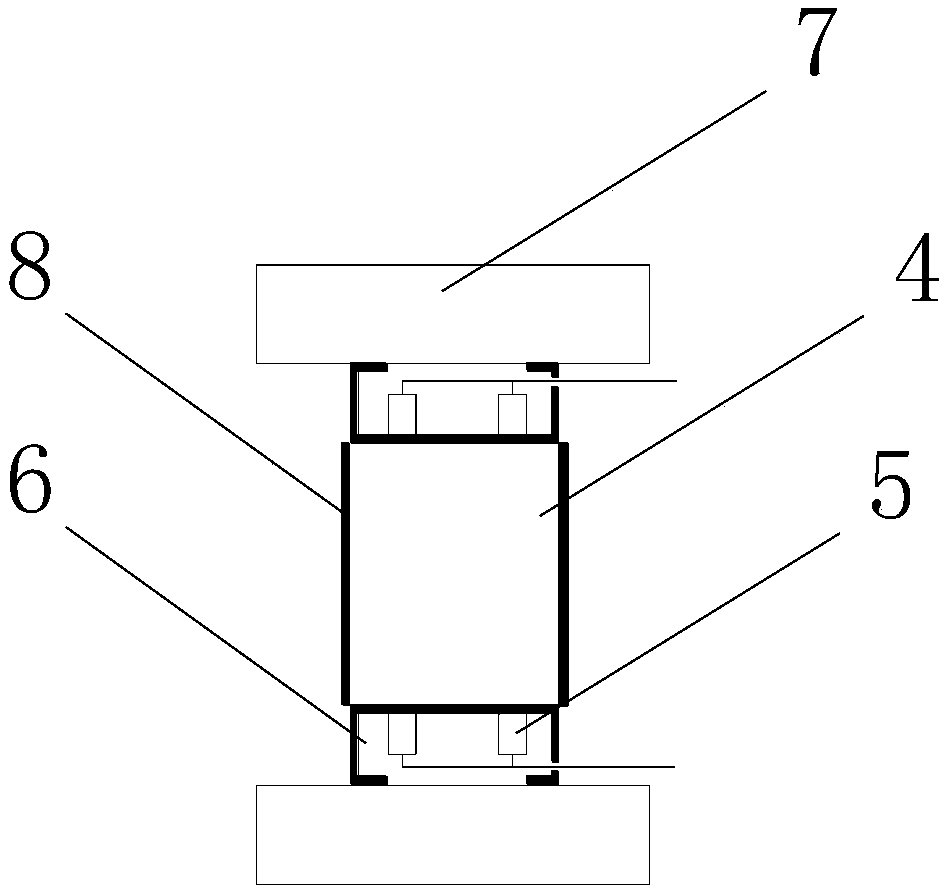

[0019] The present invention tests and calculates the three-dimensional rock wave velocity under the in-situ stress state on the borehole wall, and then takes the oriented rock specimen back from the original rock, and processes the rock specimen in the direction of the maximum sound wave, that is, the direction of the maximum stress. Compression test and sonic test under lateral pressure. The pressure at which the wave velocity of test block 4 is equal to the maximum wave velocity of the borehole is selected as the maximum stress of the original rock in the drill hole, and the direction of the maximum sound wave is the direction of the maximum stress of the original rock. The present invention utilizes the positive correlation between the rock wave velocity and the ground stress, and the favorable condition that the change of the wave speed under the action of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com