SF6 (sulfur hexafluoride) biotoxicity testing device with video monitoring function

A biotoxic and video surveillance technology, applied in measurement devices, televisions, closed-circuit television systems, etc., can solve the problems of large test workload and long test period, and achieve the effect of constant inventory and easy monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

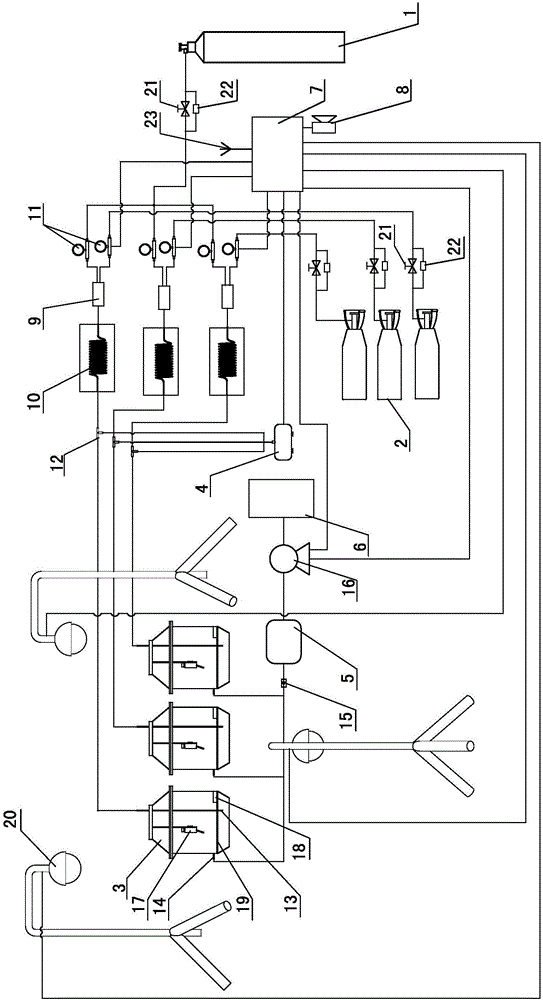

[0016] Below in conjunction with accompanying drawing, the present invention will be further described by embodiment: there are 3 poisoning boxes 3, 4 airflow control modules, 6 gas mixing modules with the same structure and 3 high-definition cameras 20 in the embodiment, each The gas mixing module corresponds to a poison exposure box 3, which is made of plexiglass with good light transmission and has a volume of 2L. Three high-definition cameras 20 surround the poison exposure box 3, and the signal output terminal is connected to the controller 7. The moving image signals of the collected mice are transmitted to the controller 7 at any time; a water feeder 17 and a feeding device 18 are arranged in the poisoning box 3 , and a stainless steel mesh 19 is provided at the bottom of the poisoning box 3 . Each oxygen cylinder 1 and each sulfur hexafluoride cylinder 2 are equipped with an air flow control module on the gas outlet pipeline, and each air flow control module includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com