Copper powder used for ultrathin vapor chamber and manufacturing method thereof

A manufacturing method and technology for a soaking plate are applied in the field of copper powder for an ultra-thin soaking plate and its production, which can solve the problems of insufficient capillary porosity, decreased capillary force, insufficient power of the soaking plate, etc., and achieve no powder filling. The effect of defects, uniform and dense powder filling, excellent flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

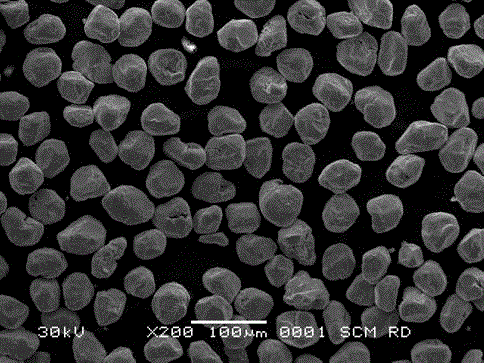

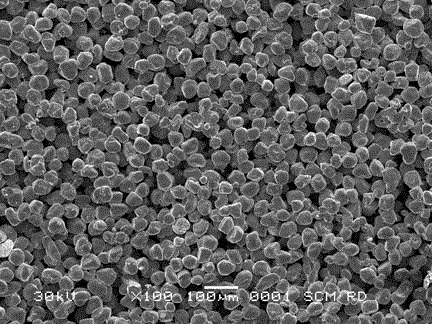

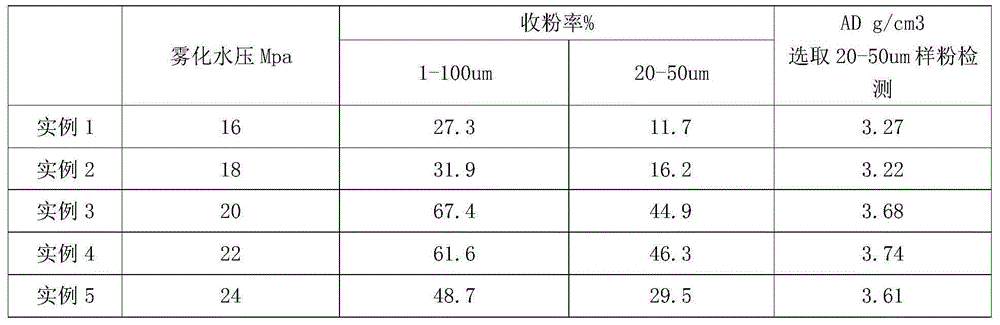

[0019] The present invention will be described in further detail below in conjunction with the examples and experimental test results.

[0020] The detection method of the present invention is: use the copper powder to prepare a sample and sinter to form a capillary structure, and then detect the connected porosity and water absorption flux of the capillary structure.

[0021] Capillary connected porosity is referred to as capillary connectivity, which refers to the ratio of the volume of pores in the capillary structure that can communicate with the outside world to the total volume of the capillary structure. The sample preparation method and calculation method are:

[0022] Put the copper powder into the cuboid graphite box mold, the size of the graphite box mold powder filling space is A*B*C, put the mold filled with the powder sample into the sintering furnace for sintering, the sintering temperature is 980±2 degrees for 30 minutes, and sintering After the completion, a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com