Integral easting method of cast steel supporting roller

A technology of integral casting and steel support, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of long production cycle, high cost, increased cost, etc., to improve productivity, ensure surface quality, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

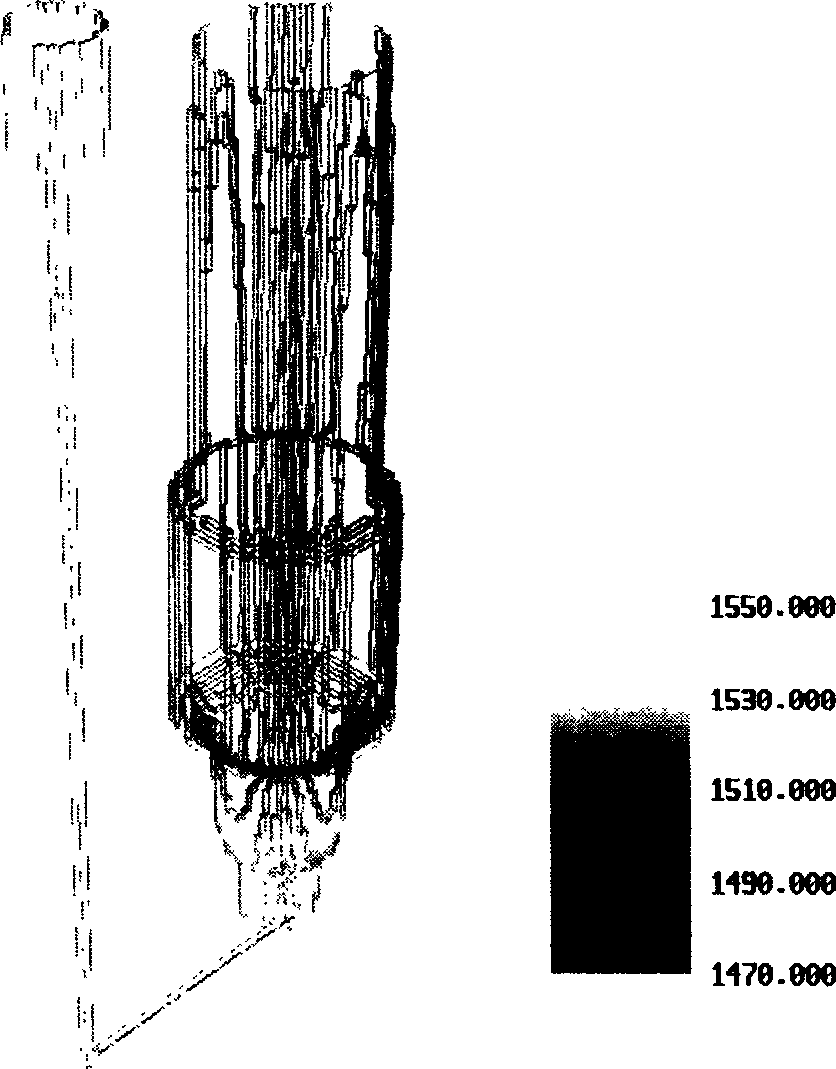

[0041] The material of this embodiment is 40Cr4, and the liquidus temperature of this material is 1470°C. The pouring temperature is 1550°C, the weight of the molten metal is 50 tons, and the pouring speed is 10 tons per minute. Its casting process is as follows:

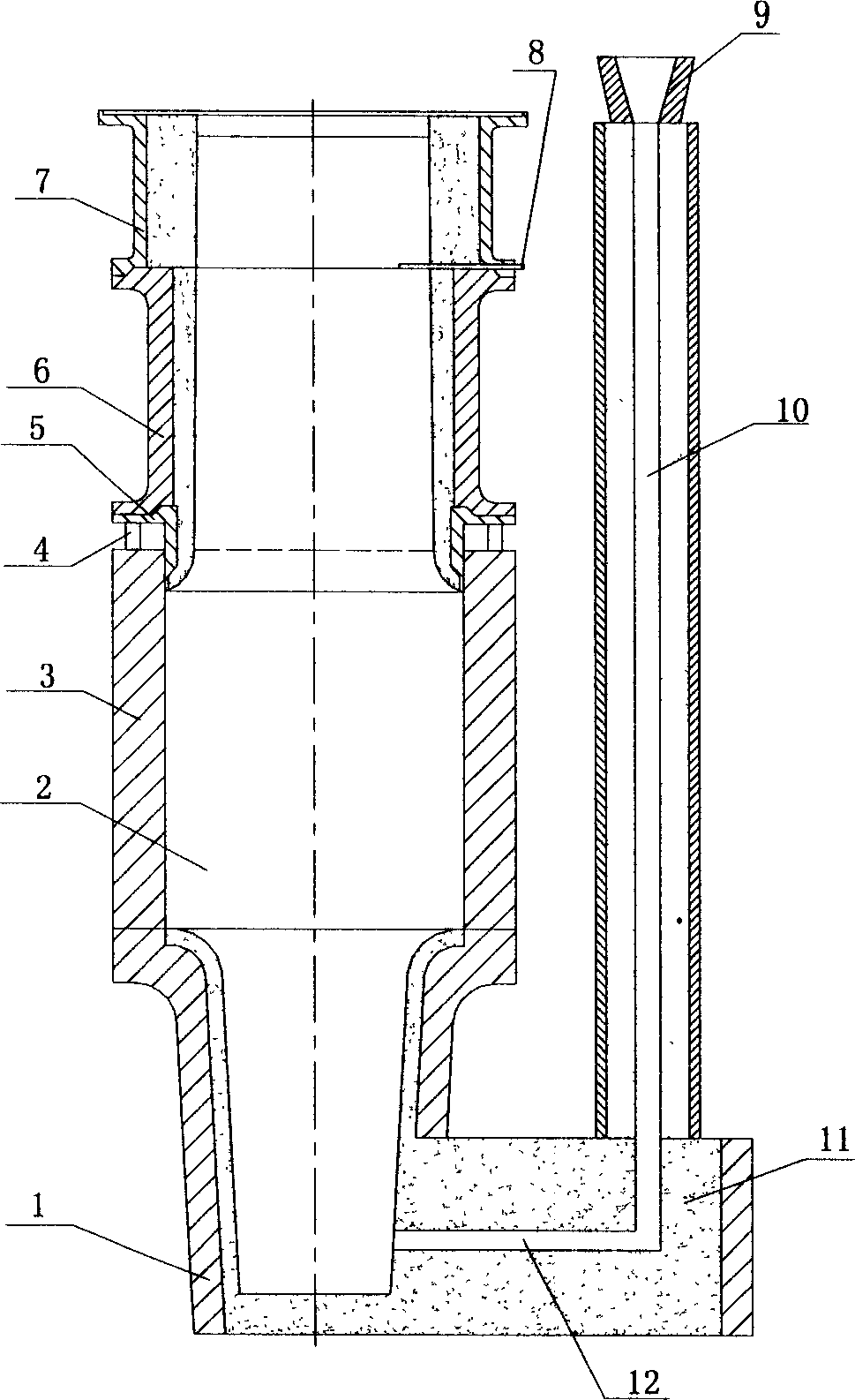

[0042] 1) Design the sprue cup and pouring system according to the principle of smooth filling, and use tangential ingate rotary pouring.

[0043] 2) The sprue and runner are formed with chromite sand. The diameter of the sprue inlet is 130mm, the outlet diameter is 75mm, and the diameter of the runner is 75mm.

[0044] 3) Both the roll body and the lower roll neck iron mold are covered with chromite sand, and the thickness of the sand layer is 10-30mm. The thickness of the iron mold at different parts is 120-500mm; the taper of the upper roll neck is 2%.

[0045] 4) The thermal insulation riser should be surrounded by thermal insulation board 16, its root diameter is 1050mm, the upper part of the riser is retrac...

Embodiment 2

[0051] The material is 40Cr4, the pouring temperature is 1520°C, the weight of the molten metal is 48 tons, and the pouring speed is 9 tons per minute. Its casting process is as follows:

[0052] 1) The sprue cup and gating system are designed according to the principle of smooth filling, and the tangential ingate rotary pouring technology is still used.

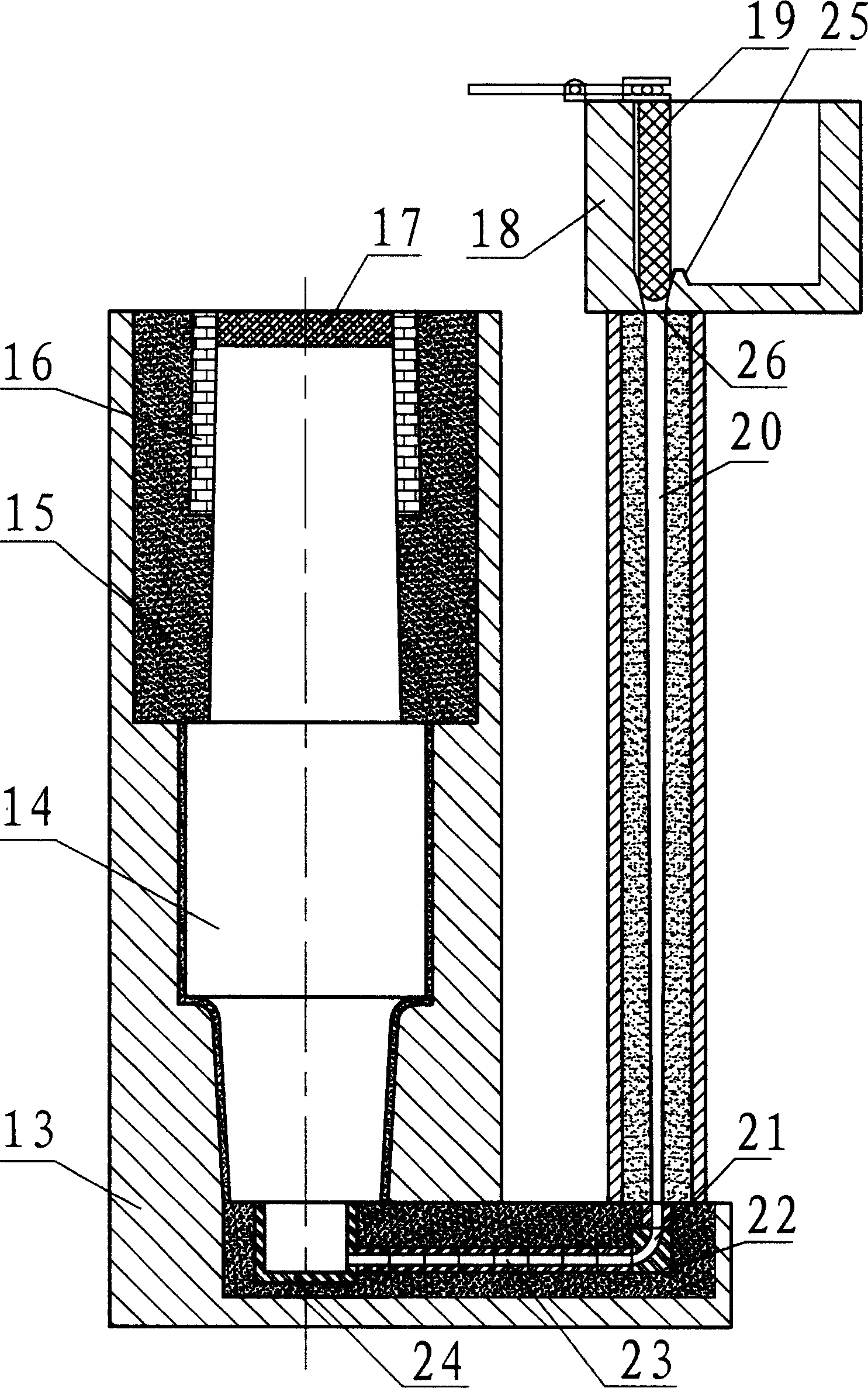

[0053] 2) Both the sprue and the runner are formed with shaped refractory bricks, and the base cavity is also formed with shaped barrel bricks 24, which form a tangential ingate with the runner. The diameter of the shaped barrel brick 24 is 350mm, and The height is 350mm. The diameter of the sprue inlet is 120mm, the outlet diameter is 70mm, and the diameter of the runner is 70mm.

[0054] 3) Both the roll body and the lower roll neck iron mold are covered with chromite sand, and the thickness of the sand layer is 15-30mm. The thickness of the iron mold at different parts is 120-500mm; the taper of the upper roll neck is ...

Embodiment 3

[0061] The material is 40Cr4, the pouring temperature is 1540°C, the weight of the molten metal is 47 tons, and the pouring speed is 8 tons per minute. Its casting process is as follows:

[0062] 1) The sprue cup is designed according to the principle of smooth filling, and the tangential inner gate rotary pouring technology is still used.

[0063] 2) Both the sprue and the runner are formed with shaped refractory bricks, and the base cavity is also formed with shaped barrel bricks 24, which form a tangential ingate with the runner. The diameter of the shaped barrel brick 24 is 350mm, and The height is 350mm. The diameter of the sprue inlet is 120mm, the outlet diameter is 65mm, and the diameter of the runner is 65mm.

[0064] 3) Both the roll body and the lower roll neck iron mold are covered with chromite sand, and the thickness of the sand layer is 15-30mm. The thickness of iron molds in different parts is 120-500mm.

[0065] 4) The thermal insulation riser should be su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com