Polyester fiber coconut fiber plate and preparation method thereof

A polyester fiber, coconut palm board technology, applied in textiles, papermaking, non-woven fabrics and other directions, can solve the problems of human sleep hazards, uneven thickness, physical disadvantages, etc., to improve the natural taste of environmental protection, reduce labor costs, production simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

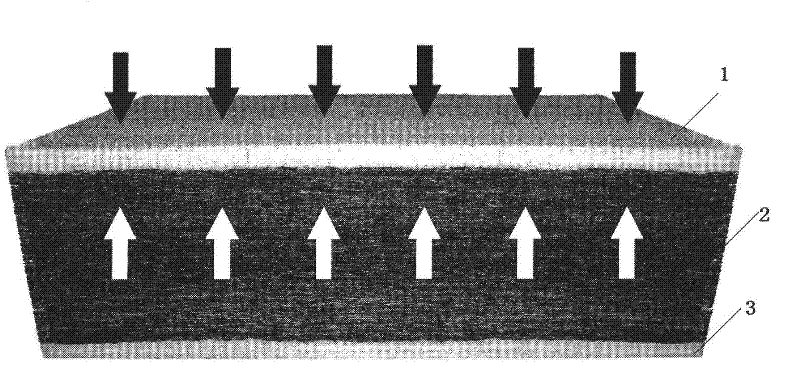

[0034] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

[0035] The present embodiment provides a kind of preparation method of polyester fiber coconut palm board, and implementation process is realized by 11 road process equipments, and concrete steps are as follows:

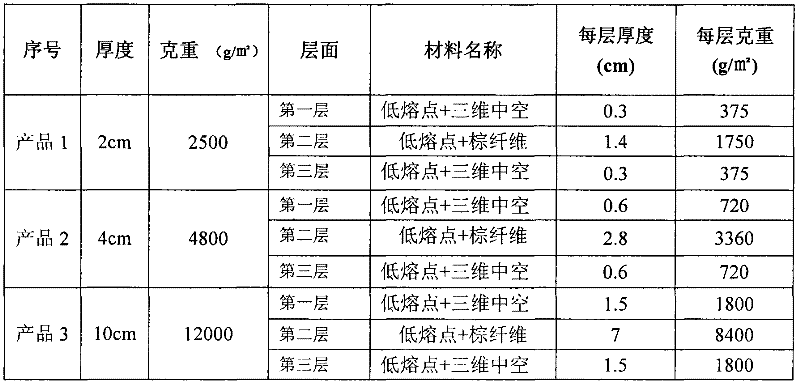

[0036] First, the batching bin: according to the multi-layer material formula, the upper and lower sides have low melting point bi-component skin-core fibers and three-dimensional curled round hollow fibers, and the batching is carried out according to the thickness and hardness of the material. These can be configured according to existing common sense, as shown in the following table, which is part of the configured content.

[0037] Second, feeding machine: evenly spread the prepared raw materials on the batching machine, and auto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com