One-step molding mattress

A mattress and technology, which is applied in the field of one-time forming multifunctional healthy mattress and its preparation, can solve the problems of harmfulness to the user's body and the environment, harmful substances of formaldehyde, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

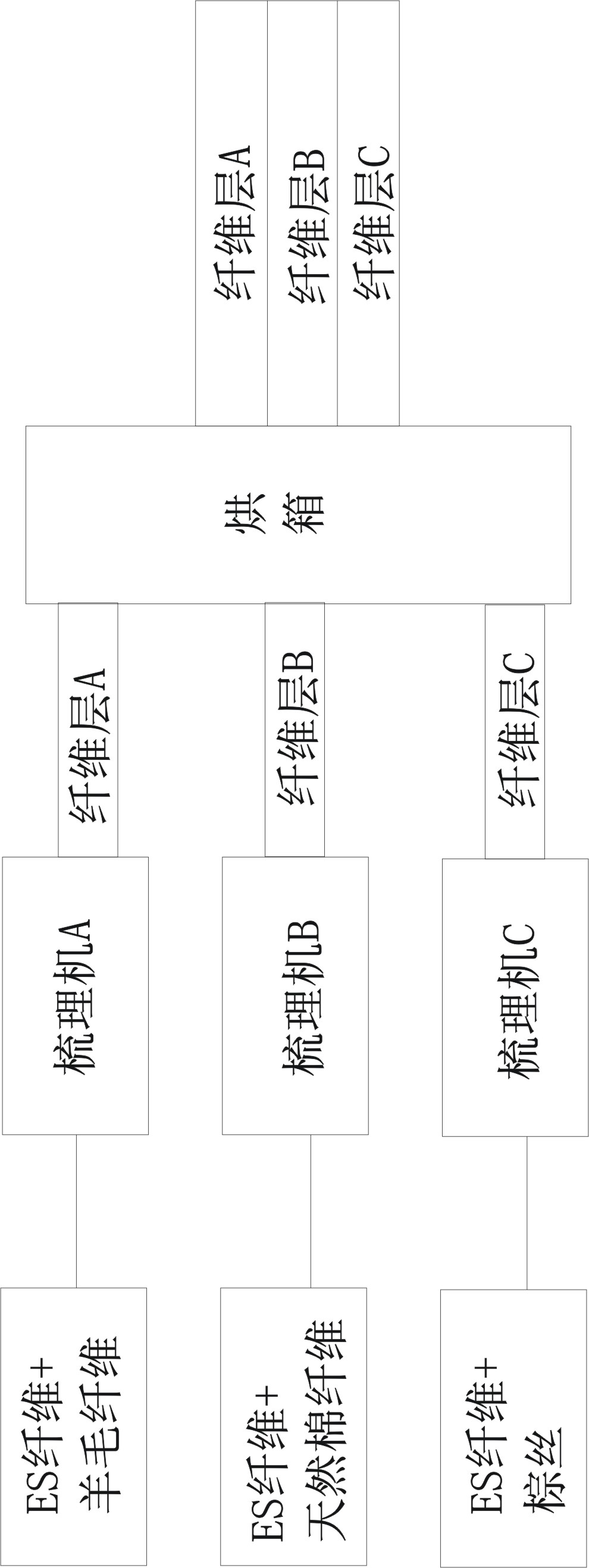

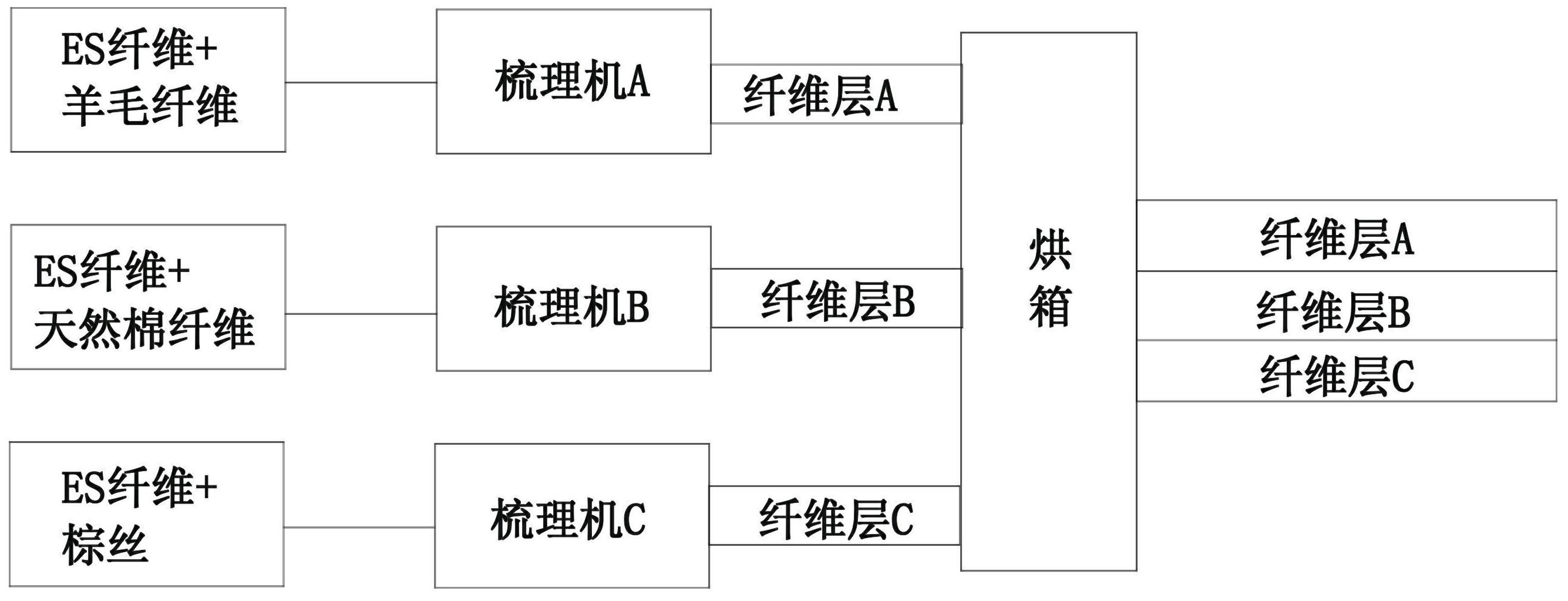

[0012] The process of preparing a one-time forming mattress is as follows, and the process flow chart is as follows: figure 1 Shown.

[0013] Take 20% by weight of ES fiber and 80% of wool fiber and mix them evenly and put them in carding machine A for carding. After carding, fiber layer A is evenly spread on the belt;

[0014] Take 20% ES fiber and 80% natural cotton fiber by weight percentage and mix them evenly and put them into carding machine B for carding. After carding, fiber layer B is evenly spread on the belt;

[0015] Take 20% by weight of ES fiber and 80% of brown silk and mix them evenly and put them into carding machine C for carding. After carding, fiber layer C is evenly spread on the belt;

[0016] The fiber layer A, fiber layer B, and fiber layer C laid on the belt are fed into the same oven and stacked together for heat treatment, and baked at 220°C for 5 minutes. During the heat treatment process, the ES fiber is heated and melted. The molten ES fiber forms a cert...

Embodiment 2

[0018] Take 20% of ES fiber and 80% of natural cotton fiber by weight and mix them evenly and put them into carding machine A for carding. After carding, fiber layer A is evenly spread on the belt;

[0019] Take 20% of the ES fiber and 80% of the brown silk by weight and mix them evenly and put them into the carding machine B for carding. The carded fiber layer B is evenly spread on the belt;

[0020] The fiber layer A and fiber layer B laid on the belt are sent to the same oven and stacked together for heat treatment, and baked at a temperature of 200°C to 220°C for 5 to 6 minutes. During the heat treatment process, the ES fiber is heated and melted , The molten ES fiber forms a certain number of thermal bonding points at the connection between the fiber layer A and the fiber layer B, and the fiber layer A and the fiber layer B are bonded into one with two layers through the bonding effect of the ES fiber The whole of different fiber layers, after finally being pressed (pressure 3...

Embodiment 3

[0022] Take 20% by weight of ES fiber and 80% of wool fiber and mix them evenly and put them in carding machine A for carding. After carding, fiber layer A is evenly spread on the belt;

[0023] Take 20% ES fiber and 80% natural cotton fiber by weight percentage and mix them evenly and put them into carding machine B for carding. After carding, fiber layer B is evenly spread on the belt;

[0024] Take 20% of the ES fiber and 80% of the three-dimensional crimped hollow cotton fiber by weight and mix them evenly and put them into the carding machine C for carding. The carded fiber layer C is evenly spread on the belt;

[0025] Take 20% by weight of ES fiber and 80% of natural hemp fiber and mix them evenly and put them into carding machine D for carding. After carding, the fiber layer D is evenly spread on the belt;

[0026] The fiber layer A, fiber layer B, fiber layer C and fiber layer D laid on the belt are sent to the same oven and stacked together for heat treatment, and baked at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com