Composite modified starch emulsion for coating and preparation method of emulsion

A technology of compounding modified starch and starch milk, applied in the direction of coating, can solve the problems of hot stickiness and cold brittleness, poor solvent resistance, high hardness, etc., and achieve the effect of improving heat resistance, good emulsification and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] 3. The preparation process of acid hydrolyzed hydroxypropyl starch is as follows: in deionized water, add a swelling inhibitor relative to the starch mass ratio of 13%, add sodium hydroxide accounting for 1.0% of the starch mass, mix and stir until dissolved, and add the step (1) Adjust the prepared acid-thinned starch into 35% starch milk, stir and alkalinize for 40 minutes, heat up to 42°C, add propylene oxide accounting for 5% of the starch mass, etherify for 14 hours, add 10% hydrochloric acid to adjust the pH to 7.0, after centrifugal dehydration, drying and sieving, the acid hydrolyzed hydroxypropyl starch can be obtained;

[0047] 4. The preparation process of acid-thinned starch used in the preparation process of acid-thinned carboxymethyl starch and acid-thinned hydroxypropyl starch is as follows: add HCl solution with a mass percentage concentration of 0.6% to the starch, and prepare starch with a concentration of 38%. Milk, heated to 50°C, acidolysis for 2 ho...

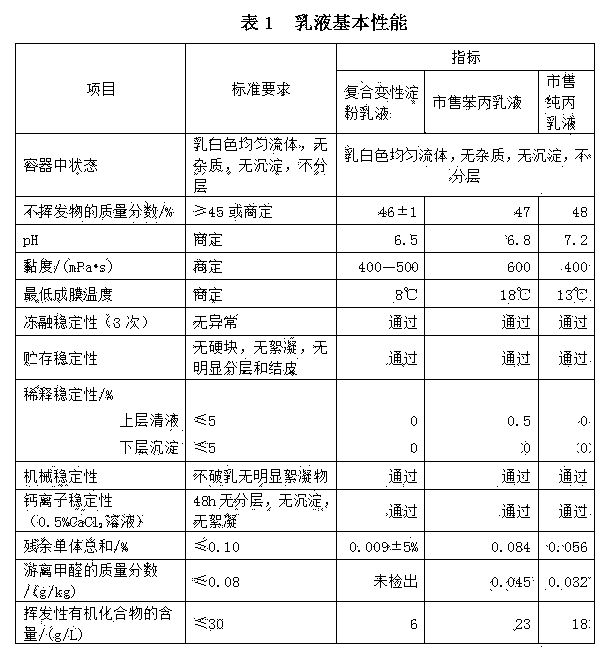

Embodiment 1

[0054] The amount of raw materials is as follows: 60 kg of oxidized starch, 40 kg of acid-decomposed etherified starch, 2 kg of swelling inhibitor, 0.03 kg of crosslinking agent, 35 kg of hard monomer, 65 kg of soft monomer, 1 kg of functional monomer, and 2 kg of emulsifier , 1 kg of initiator, 200 kg of deionized water, and 1.2 kg of NaOH.

[0055] The preparation method of composite modified starch emulsion for coating comprises the steps:

[0056] (1) In the state of stirring, add oxidized starch and acid-hydrolyzed etherified starch in deionized water in parts by mass (acid-lyzed carboxymethyl starch sodium with a degree of substitution of 0.4 and acid-lyzed hydroxypropyl starch with a degree of substitution of 0.1 1:2 ratio) to form a certain concentration of starch milk;

[0057] (2) In step (1), the starch milk obtained in step (1) is added with a proportional expansion inhibitor sodium chloride, and the pH of the starch milk is adjusted to 10.5 with a sodium hydroxid...

Embodiment 2

[0065] The amount of raw materials is as follows: 70 kg of oxidized starch, 30 kg of acid-decomposed etherified starch, 1.5 kg of swelling inhibitor, 0.02 kg of crosslinking agent, 80 kg of hard monomer, 120 kg of soft monomer, 4 kg of emulsifier, and 2.5 kg of initiator , 300 kg of deionized water, and 1.5 kg of NaOH.

[0066] The preparation method of composite modified starch emulsion for coating comprises the steps:

[0067] (1) In the state of stirring, add oxidized starch and acid-hydrolyzed etherified starch in deionized water in parts by mass (acid-lyzed sodium carboxymethyl starch with a degree of substitution of 0.8 and acid-lyzed hydroxypropyl starch with a degree of substitution of 0.08 and 1:4 ratio) to form a certain concentration of starch milk;

[0068] (2) In the starch milk obtained in step (1), add the expansion inhibitor sodium chloride in proportion, and adjust the pH of the starch milk to 11 with a sodium hydroxide solution with a volume concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com