Novel environment-friendly dyeing method for jeans apparel

A dyeing method and technology for garments, applied in dyeing methods, textiles and papermaking, dry cleaning fiber products, etc., can solve the problems of high dyeing cost of denim garments, poor dyeing color fastness, environmental pollution, etc., and achieve good practical value and reduce Energy and material consumption, process energy saving and environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

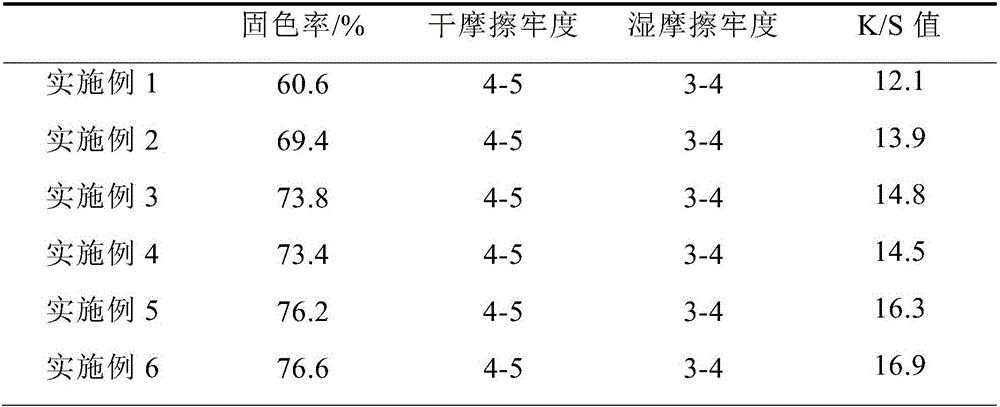

Examples

Embodiment 1

[0031] 1) Pretreatment: desizing:

[0032] Desizing formula (per liter): Premix M100 amylase 3.0g, non-ionic penetrant Goon106 0.5g, citric acid 0.6mL, softener H-413 0.5g.

[0033] Process conditions: pH value 6.0, liquor ratio 1:20, temperature 40-90°C, time 30 minutes; add citric acid to the desizing solution, adjust pH 6.0-7.0, so that Premix M100 amylase can exert its best performance.

[0034] 2) Prepare modified solution:

[0035] (1) Add 987.5 kg of deionized water to the reactor, start the stirring device, add 4 kg of cationic guar gum, stir well, add 0.5 kg of citric acid, heat up to 70-75 ° C for 20 minutes, and cool down after the reaction is completed At 30°C, a clear and transparent cationic guar gum thickened liquid with a viscosity of 2000-3000mPa.s is obtained.

[0036] (2) Add 5.5kg of dodecyltrimethylammonium chloride in the cationic guar gum thickening solution, stir evenly at normal temperature, then add 2.5kg of penetrant isomer thirteen in the reactor ...

Embodiment 2

[0046] 1) Pretreatment: desizing:

[0047]Desizing formula (per liter): 1.0 g of Premix M100 amylase, 2.5 g of commercially available Goon106 non-ionic penetrating agent, 1.5 mL of citric acid, and 2.0 g of commercially available H-413 softener.

[0048] Process conditions: pH value 7.0, bath ratio 1:15, temperature 40-90°C, time 30 minutes; add citric acid to the desizing solution, adjust pH 6.0-7.0, so that Premix M100 amylase can exert its best performance.

[0049] 2) Prepare modified solution:

[0050] (1) Add 910kg of deionized water into the reactor, start the stirring device, add 4kg of cationic guar gum, stir well, add 0.5kg of citric acid, heat up to 70-75°C for 20min, and cool down to At 30°C, a clear and transparent cationic guar gum thickened liquid with a viscosity of 3000mPa.s was obtained.

[0051] (2) add the dodecyltrimethylammonium chloride of 6kg in the described cationic guar gum thickener, stir under normal temperature, then add the commercially availab...

Embodiment 3

[0061] 1) Pretreatment: desizing:

[0062] Desizing formula (per liter): 2.0 g of Premix M100 amylase, 1.5 g of commercially available Goon106 non-ionic penetrating agent, 1 mL of citric acid, and 1.5 g of commercially available H-413 softener.

[0063] Process conditions: pH value 6.0-7.0, liquor ratio 1:15, temperature 40-90°C, time 30 minutes; add citric acid to the desizing solution, adjust pH 6.0-7.0, so that Premix M100 amylase can exert the best performance.

[0064] 2) Prepare modified solution:

[0065] (1) Add 1000 kg of deionized water to the reactor, start the stirring device, add 3 kg of cationic guar gum, stir well, add 0.6 kg of citric acid, heat up to 70-75 ° C for 20 minutes, and cool down to At 30°C, a clear and transparent cationic guar gum thickened liquid with a viscosity of 2500mPa.S was obtained.

[0066] (2) Add 0.6kg of lauryltrimethylammonium chloride in the cationic guar gum thickener, stir evenly at normal temperature, then add 3kg of penetrating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com