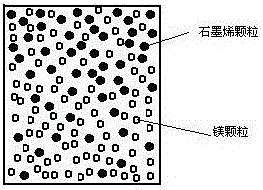

Preparation method of gradient graphene/magnesium composite material

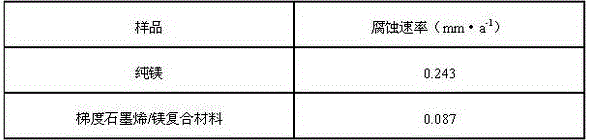

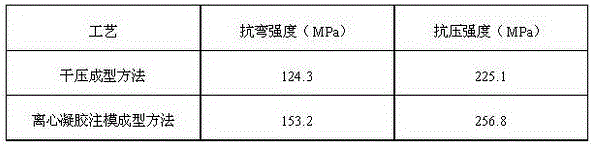

A composite material and graphene technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of less research on corrosion resistance and mechanical properties of magnesium matrix, avoid delamination and cracks, and improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] 1. Preparation of graphene / magnesium composite slurry

[0022] In parts by mass, 5 parts of organic monomer hydroxyethyl methacrylate (HEMA) and 1 part of crosslinking agent trimethylolpropane triacrylate (TMPTA) were dissolved in 60.25 parts of n-butanol, and stirred evenly. Then add 1.5 parts of dispersant oleic acid, stir well, then add 27 parts of magnesium powders with a particle size of 60nm and 3 parts of graphene powder with a particle size of 500nm, stir well; add 2 parts of initiator benzoyl peroxide ( BPO) and 0.25 parts of the catalyst N,N dimethylaniline (DMA), and stirred evenly to make a graphene / magnesium composite slurry.

[0023] 2. Centrifugation, gel curing and sintering

[0024] a. Inject the above-mentioned prepared graphene / magnesium multiphase slurry into the inner mold of the centrifuge, and centrifuge for 20min at a speed of 500r / min, so that the graphene and magnesium particles form a continuous gradient distribution;

[0025] b. Put the c...

example 2

[0027] 1. Preparation of graphene / magnesium composite slurry

[0028] In parts by mass, 15 parts of organic monomer hydroxyethyl methacrylate (HEMA) and 3 parts of crosslinking agent trimethylolpropane triacrylate (TMPTA) were dissolved in 29.125 parts of n-butanol, and stirred evenly. Then add 2.25 parts of dispersant oleic acid, stir evenly, then add 40.5 parts of particle size as magnesium powder of 60nm and 4.5 parts of graphene powder of particle size 500nm, stir evenly; Add 5 parts of initiator benzoyl peroxide ( BPO) and 0.625 parts of catalyst N,N dimethylaniline (DMA), stirred evenly to make graphene / magnesium composite slurry.

[0029] 2. Centrifugation, gel curing and sintering

[0030] a. The above-mentioned prepared graphene / magnesium slurry is injected into the mold in the centrifuge, and centrifuged for 10min at a speed of 2000r / min, so that the graphene and magnesium particles form a continuous gradient distribution;

[0031] b. Put the centrifuged slurry i...

example 3

[0033] 1. Preparation of graphene / magnesium composite slurry

[0034] In parts by mass, 10 parts of organic monomer hydroxyethyl methacrylate (HEMA) and 2 parts of crosslinking agent trimethylolpropane triacrylate (TMPTA) were dissolved in 47.875 parts of n-butanol, and stirred evenly. Then add 1.75 parts of dispersant oleic acid, stir evenly, then add 31.5 parts of particle size as magnesium powder of 60nm and 3.5 parts of graphene powder of particle size 500nm, stir evenly; Add 3 parts of initiator benzoyl peroxide ( BPO) and 0.375 parts of catalyst N,N dimethylaniline (DMA), stirred evenly to make graphene / magnesium composite slurry.

[0035] 2. Centrifugation, gel curing and sintering

[0036] a. The above-mentioned prepared graphene / magnesium slurry is injected into the inner mold of the centrifuge, and centrifuged for 15min at a speed of 1000r / min, so that the graphene and magnesium particles form a continuous gradient distribution;

[0037] b. Put the centrifuged sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com