Additive manufacturing device capable of conducting magnetic field control and parent metal transport

A technology for additive manufacturing and control devices, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement. It can solve the problems of limited control means for solidified tissue in laser three-dimensional forming, expand the range of printable materials, improve the use performance, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

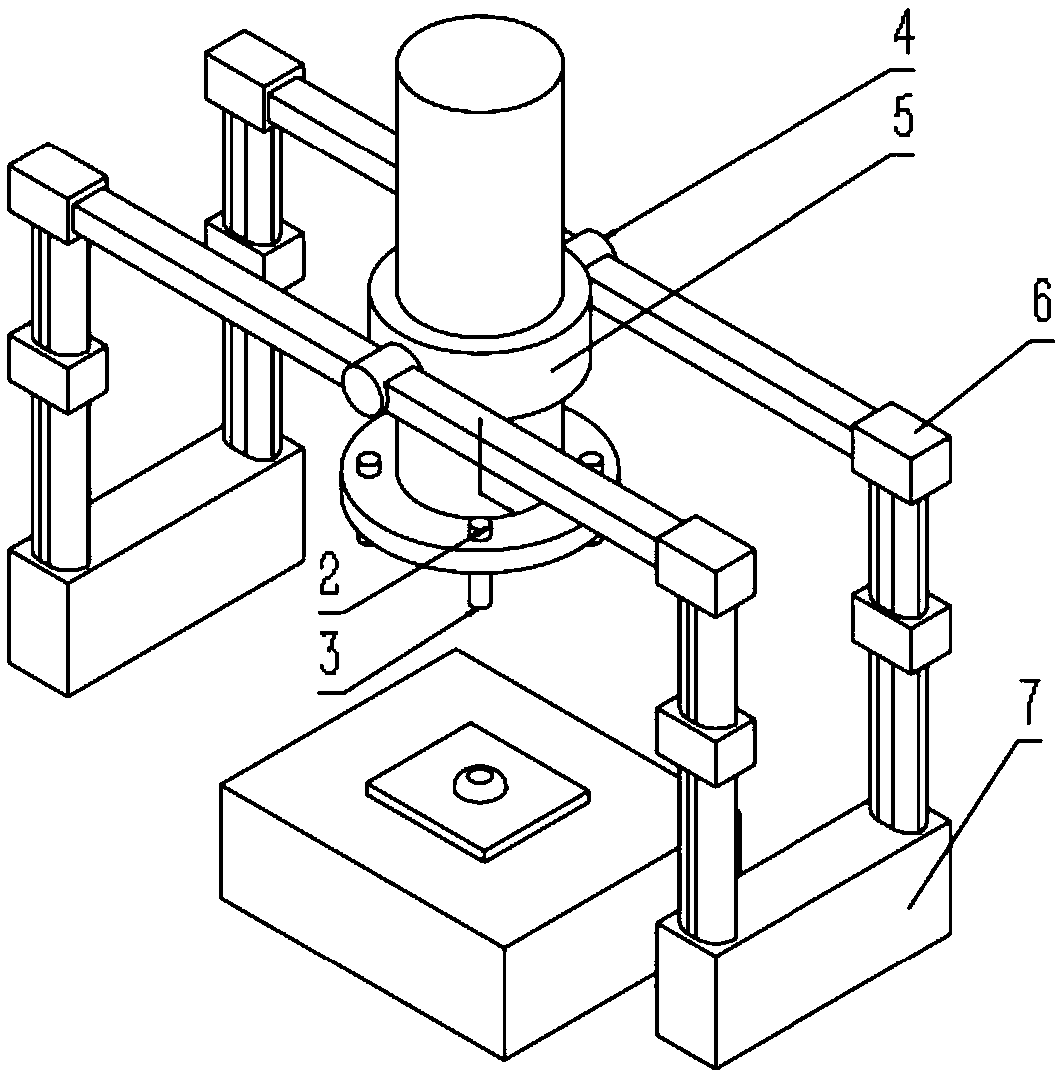

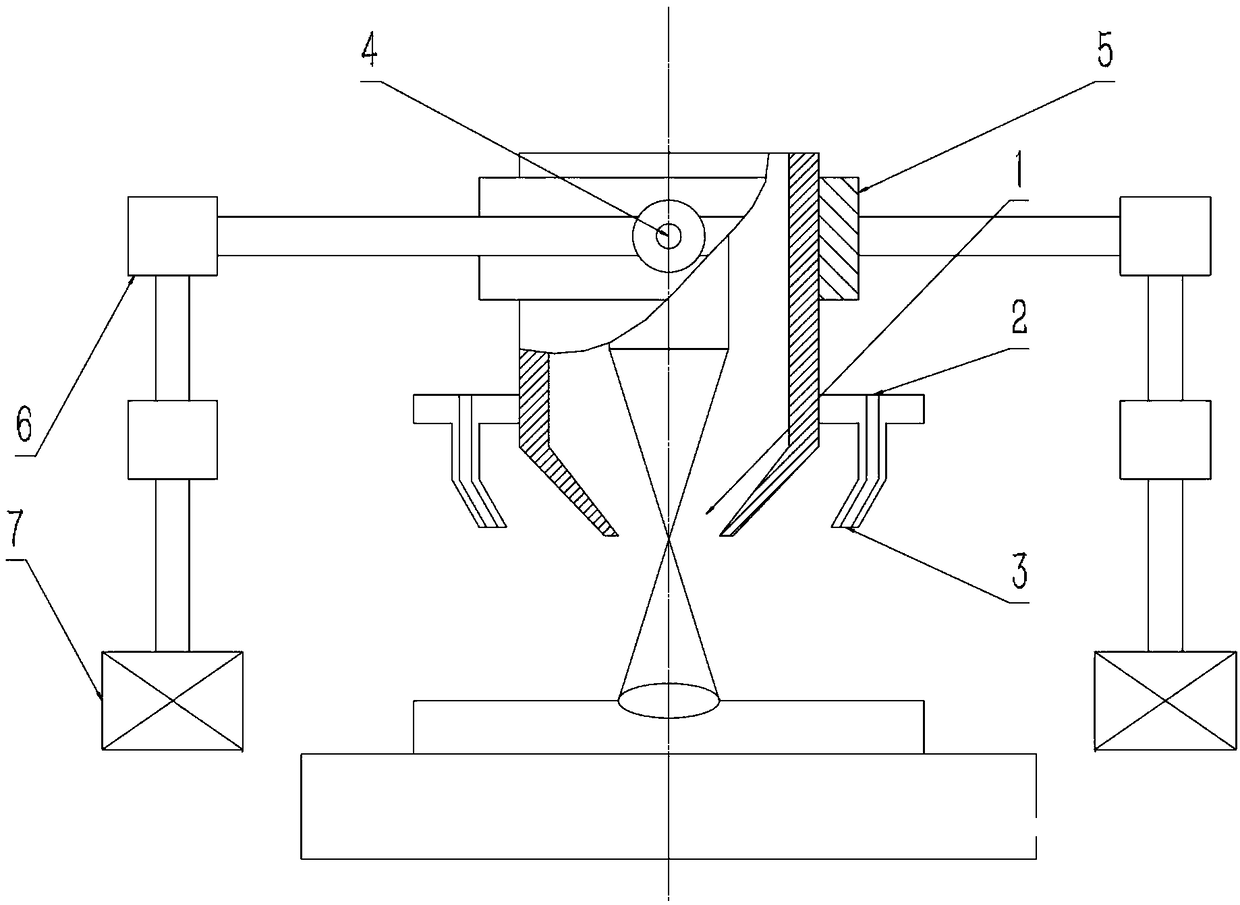

[0037] In this example, see figure 1 with figure 2 , an additive manufacturing device capable of magnetic field control and parent material transportation, mainly including the rack body of the additive manufacturing device, a control device, a laser device, a power supply device, a raw material supply device and a working platform, and the parts to be manufactured are working Prepared on the substrate on the platform, the control device mainly sends control instructions to each device after data processing according to the information collected by the corresponding device and the information input by the user, the power supply device provides electric energy for each device, and the laser device mainly includes a laser emitter The laser emitter light source device is fixedly installed on the frame body of the additive manufacturing device, providing a laser heat source with adjustable radiation direction and power, and setting the focus of the emitted laser beam on the subst...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In this embodiment, the additive manufacturing base material transport device adopts the wire material conveying method to provide raw materials for the additive manufacturing process. The wire base material is directly sent to the substrate on the working platform from the wire material transport outlet 1, and is laser After melting, a molten pool is formed. In this embodiment, when wire printing is performed, the base material is directly sent from the wire material delivery outlet 1 to the substrate of the workbench, and is melted by the laser to form a molten pool. Others are the same as the powder feeding printing method adopted in the first embodiment. In this embodiment, the metal wire is directly transported into the melting pool through pipelines due to its special shape. In laser metal additive manufacturing, the base material powder used in Embodiment 1 is a non-magnetic mate...

Embodiment 3

[0048] This embodiment is basically the same as the previous embodiment, and the special features are:

[0049] In this embodiment, the base material transportation device for additive manufacturing adopts the powder-spreading method to provide raw materials for the additive manufacturing process, and the base material is transported by pre-powdering. The laser emitter does not move during laser scanning, and the magnetic field control device 7 and the substrate Keep relatively still, and keep the center of the part to be manufactured at the center of the magnetic field during the additive manufacturing process.

[0050] In this embodiment, during laser metal additive manufacturing, by applying an external electromagnetic field to the printing device, non-contact intervention is performed on the rapid melting-solidification process of the base material after being irradiated by laser light, thereby realizing the control of the solidification process of the metal parts. The reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com