Laser stitch welding device and welding method thereof

A technology of laser welding and welding method, which is applied in the field of depth-adaptive laser stitch welding device, and can solve problems such as difficulty in controlling the penetration depth of laser stitch welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

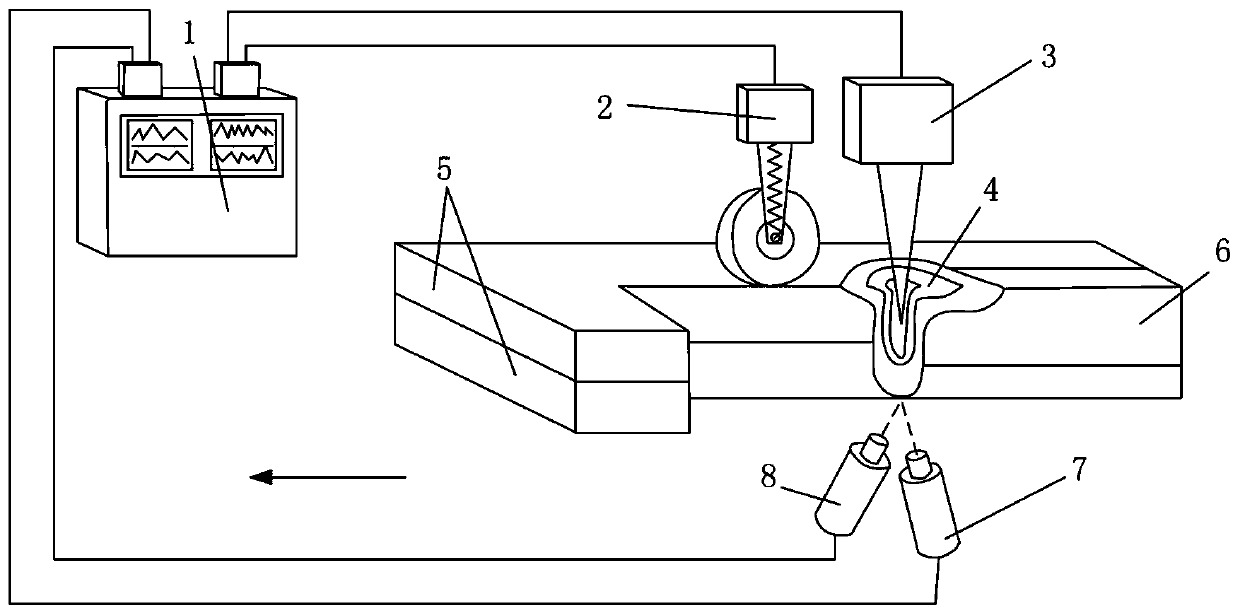

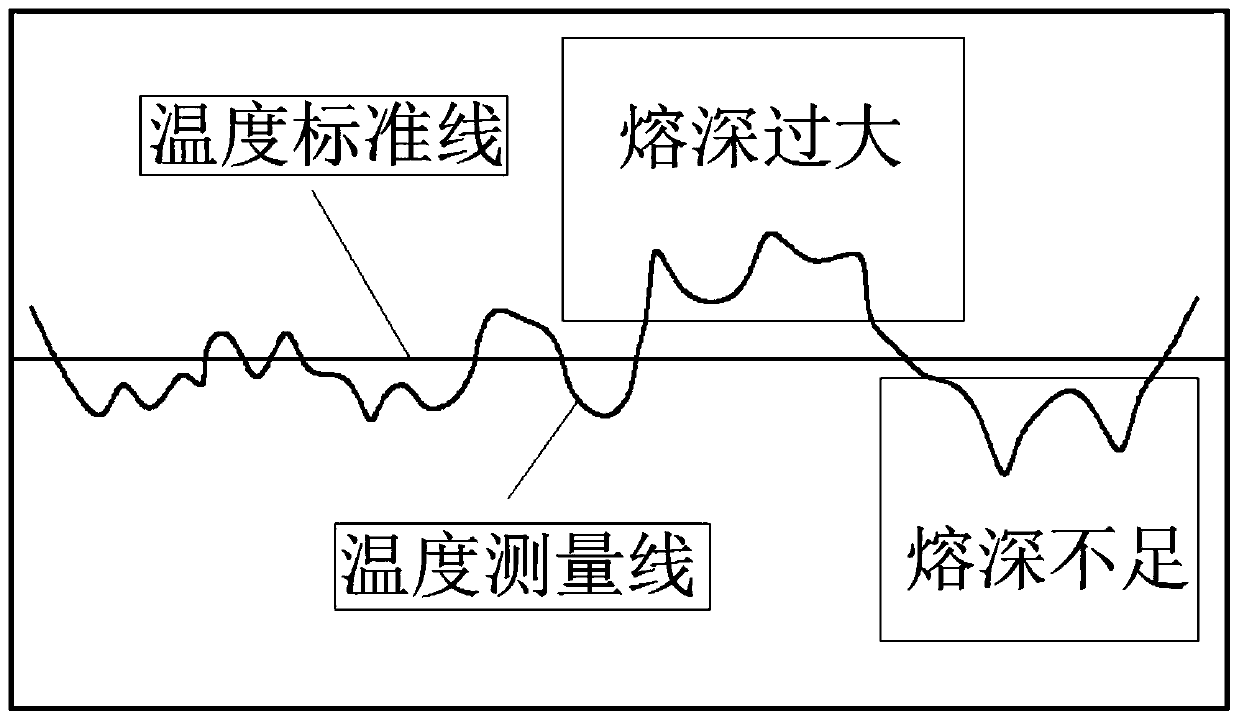

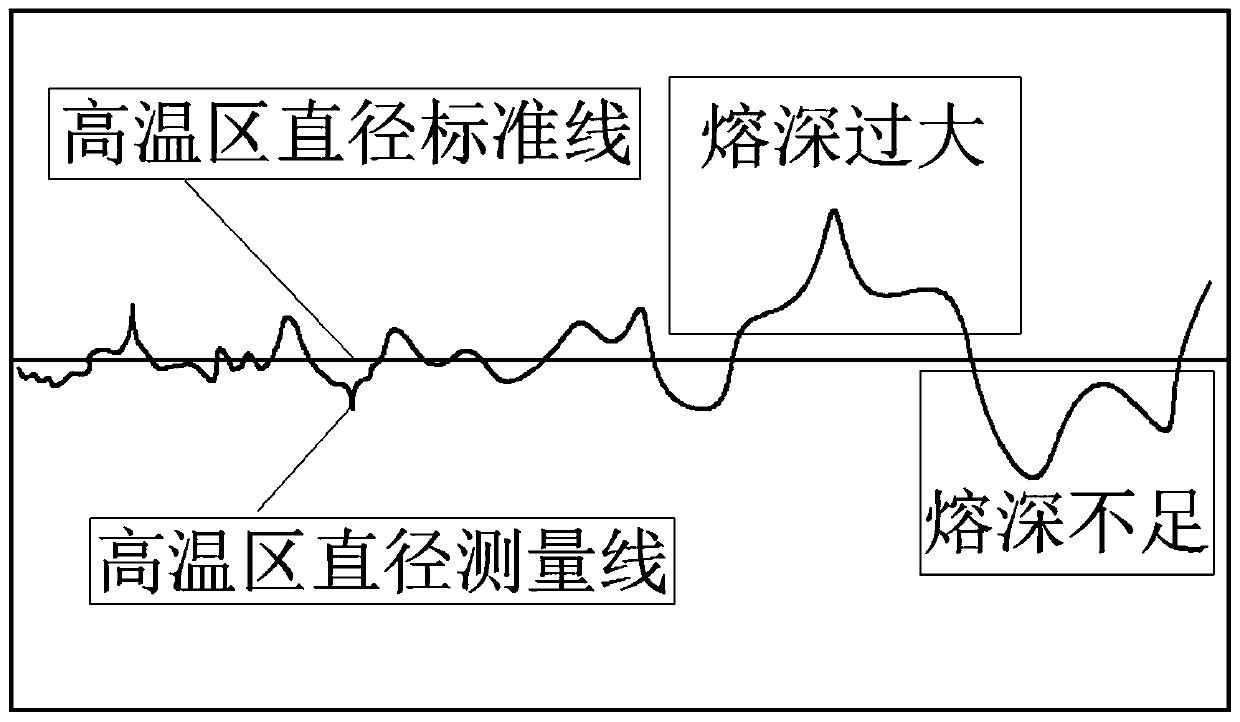

[0066] refer to figure 1 , stack the middle thin plate (i.e. the plate to be welded 5), the laser welding torch head (belonging to the laser welding assembly 3) is welded on the upper part of the middle thin plate, and a temperature (sensitive) sensor and a thermal image sensor 7 are arranged on the back of the middle thin plate relative to the bottom layer, The temperature (sensitive) sensor collects the backside temperature in real time, and the thermal image sensor 7 collects the red-hot image of the weld seam 6 in real time, and transmits the temperature value and the red-hot image of the weld seam 6 to the control system including the controller 1, and records the temperature in real time in the control system Curve and thermal image image, and compare with temperature standard line, thermal image diameter standard line.

[0067] Such as figure 2 , 3 As shown, when the depth of penetration is insufficient, the heat transfer on the back of the bottom plate to be welded ...

Embodiment 2

[0071] This embodiment provides different control methods for different comparison results in embodiment 1.

[0072] The temperature curve and thermal image images are recorded in real time in the control system, and compared with the temperature standard line and the thermal image diameter standard line.

[0073] Such as figure 2 , 3 As shown, if the depth of penetration is too large, the heat transfer on the back of the bottom plate to be welded 5 is large, the surface temperature is higher than the standard value, the high temperature area of the thermal image increases, and the diameter is greater than the standard value on the diameter standard line. At this time, the laser energy is reduced. Increase the defocus of the laser spot, or use the pulsed laser output mode (the three can be adjusted at the same time, or one or two can be selected), so as to reduce the welding penetration. In addition, in some cases, the pressing force of the pressing roller can be appropri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com