Ladderlike bainite-martensite duplex-phase steel abrasion-resistant roller sleeve and preparation method thereof

A technology of bainite and multi-phase steel, which is applied in the field of wear-resistant roller sleeves of trapezoidal bainite-martensitic multi-phase steel and its preparation, which can solve the problem of shedding of strengthening layers, high content of alloy elements, and large stress and other problems, to achieve obvious competitive advantages, simple heat treatment process, and avoid defects such as cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

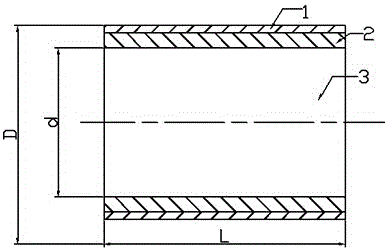

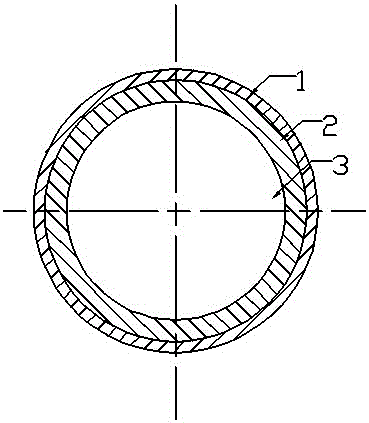

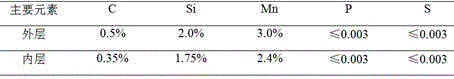

[0023] This embodiment prepares 3 tons of bainite-martensite composite phase steel centrifugal composite grinding roll sleeve, the outer wall thickness is 100mm, and the inner wall thickness is 200mm; the chemical composition mass percentage table of the inner and outer two layers of materials 1 shows:

[0024] Table 1

[0025]

[0026] The preparation method of the bainite-martensite complex phase steel centrifugal composite grinding roller sleeve described in this embodiment specifically includes the following steps:

[0027] (1) Batching: Batching is carried out according to the composition of the outer layer and the inner layer, and the intermediate frequency induction furnace is used for melting respectively.

[0028] (2) Centrifugal casting forming: First, the outer layer of molten steel is poured into the high-speed rotating casting metal mold (the temperature of the outer layer of molten steel is 1550°C, and the pouring temperature is 1470°C), and the outer layer o...

Embodiment 2

[0033] This embodiment prepares 5 tons of bainite-martensite composite phase steel centrifugal composite grinding roller sleeve, the outer wall thickness is 100mm, and the inner wall thickness is 300mm; the chemical composition mass percentage table of the inner and outer two layers of materials 2 shows:

[0034] Table 2

[0035]

[0036] The preparation method of the bainite-martensite complex phase steel centrifugal composite grinding roller sleeve described in this embodiment specifically includes the following steps:

[0037] (1) Batching: Batching is carried out according to the composition of the outer layer and the inner layer, and is smelted separately in an intermediate frequency induction furnace;

[0038] (2) Centrifugal casting forming: first pour the outer layer of molten steel into the high-speed rotating casting metal mold (the temperature of the outer layer of molten steel is 1560°C, and the pouring temperature is 1500°C), and under the action of centrifuga...

Embodiment 3

[0043] This embodiment prepares 3 tons of bainite-martensite composite phase steel centrifugal composite grinding roll sleeve, the outer wall thickness is 100mm, and the inner wall thickness is 150mm; the chemical composition mass percentage table of the inner and outer two layers of materials 3 shows:

[0044] table 3

[0045]

[0046] The preparation method of the bainite-martensite complex phase steel centrifugal composite grinding roller sleeve described in this embodiment specifically includes the following steps:

[0047] (1) Batching: Batching is carried out according to the composition of the outer layer and the inner layer, and the intermediate frequency induction furnace is used for melting respectively.

[0048] (2) Centrifugal casting forming: first pour the outer layer of molten steel into the high-speed rotating casting metal mold (the temperature of the outer layer of molten steel is 1580°C, and the pouring temperature is 1530°C), and under the action of cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com