Surface quality control method for vanadium-containing high-nitrogen round steel

A control method and surface quality technology, applied in the field of iron and steel metallurgical processing, can solve problems that affect product quality, lack of surface quality research on vanadium-containing high-nitrogen steel, and easy surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

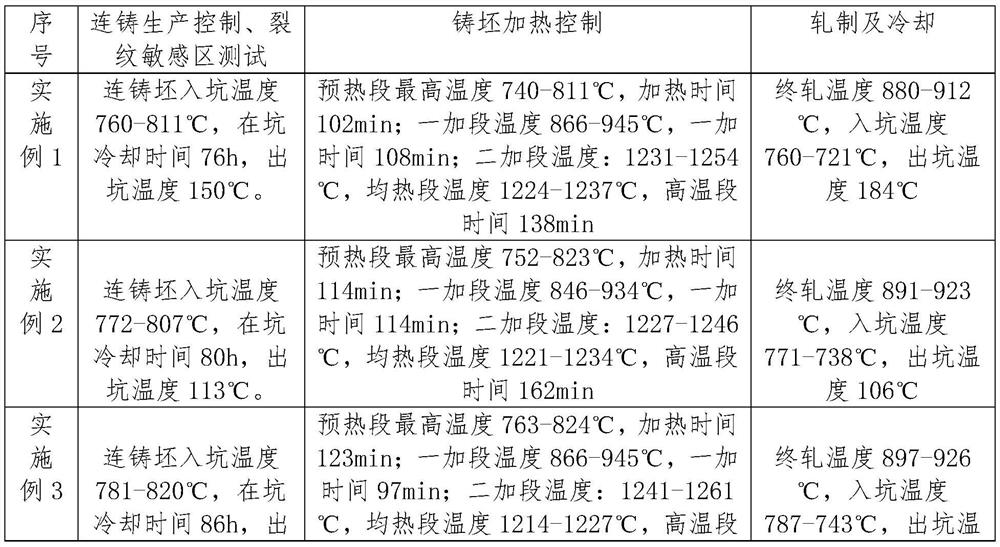

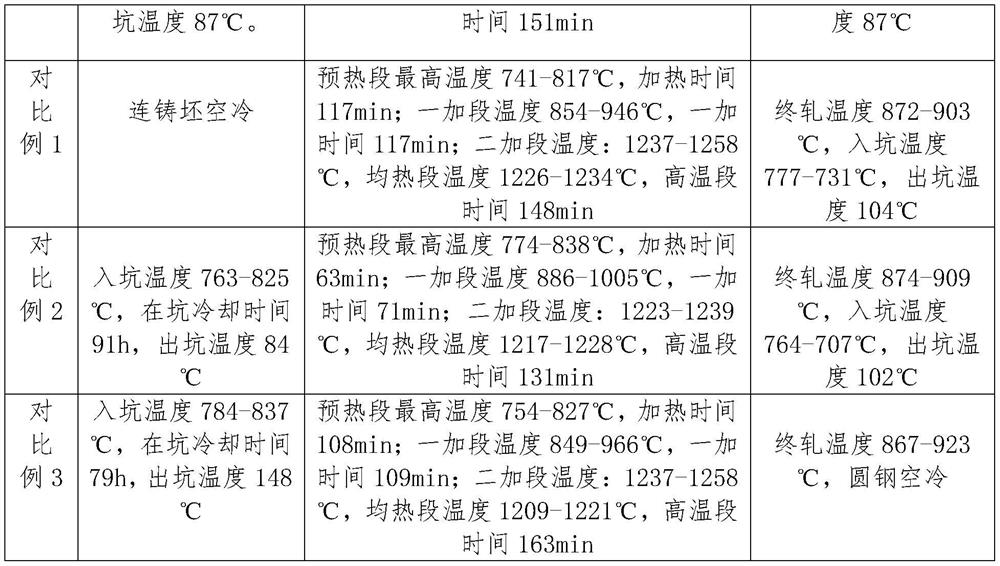

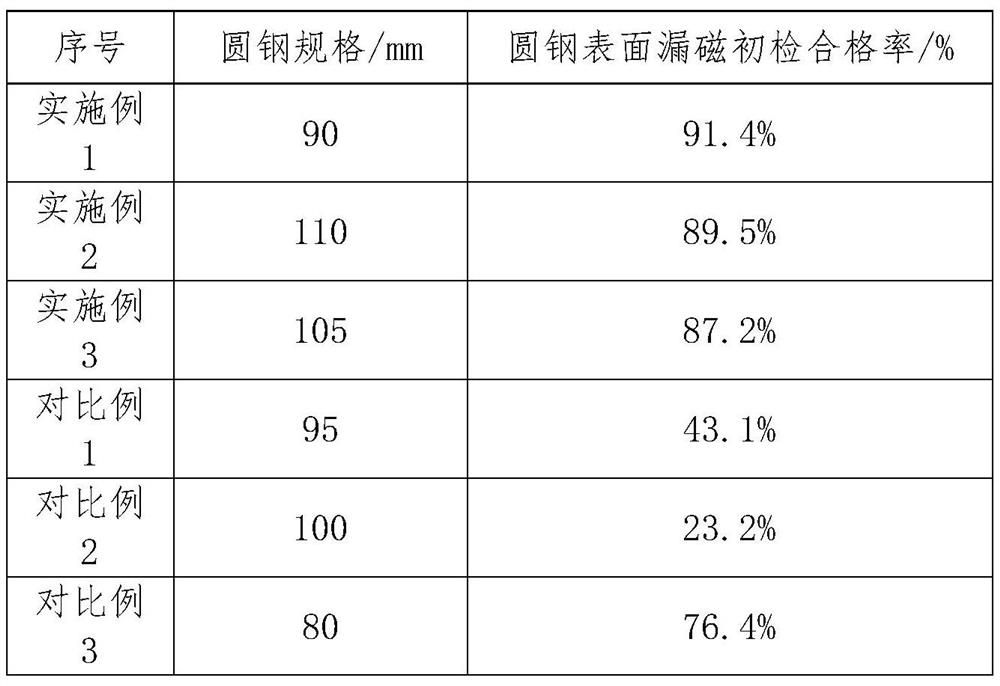

Embodiment 1

[0049] This embodiment provides a method for controlling the surface quality of vanadium-containing high-nitrogen steel, wherein the composition of the vanadium-containing high-nitrogen steel is shown in Table 1, which includes the following steps:

[0050] (1) In the production of continuous casting slabs, the secondary cooling water adopts a weak cooling method, and the cooling intensity is set at 0.23±0.02L / kg;

[0051] (2) Put the continuous casting slab into the slow cooling pit, the temperature of the continuous casting slab is controlled at 760-811°C when entering the pit, the cooling time in the pit is 76h, and the temperature out of the pit is 150°C;

[0052] (3) Use the Gleeble simulation testing machine to conduct high-temperature tensile tests to obtain a crack-sensitive temperature range of 580-660°C;

[0053] (4) For the surface inspection process of continuous casting slabs, visually check whether there are cracks on the surface and corners of each slab. Cracks...

Embodiment 2

[0059] The composition of vanadium-containing high-nitrogen steel is as shown in Table 1, and it comprises the following steps:

[0060] (1) In the production of continuous casting slabs, the secondary cooling water adopts a weak cooling method, and the cooling intensity is set at 0.23±0.02L / kg;

[0061] (2) Put the continuous casting slab into the slow cooling pit, the temperature of the continuous casting slab is controlled at 772-807°C when entering the pit, the cooling time in the pit is 80h, and the temperature out of the pit is 113°C;

[0062] (3) For the surface inspection process of continuous casting slabs, visually check whether there are cracks on the surface and corners of each slab. Cracks; if cracks are found by visual inspection or low-magnification samples, peel the billets one by one (single-side peeling ≥ 3mm);

[0063] (4) Conduct surface inspection on the continuous casting slab to be heated, adopt four-stage heating control, and perform preheating, first-...

Embodiment 3

[0068] The composition of vanadium-containing high-nitrogen steel is as shown in Table 1, and it comprises the following steps:

[0069] (1) In the production of continuous casting slabs, the secondary cooling water adopts a weak cooling method, and the cooling intensity is set at 0.23±0.02L / kg;

[0070] (2) Put the continuous casting slab into the slow cooling pit, the temperature of the continuous casting slab is controlled at 781-820°C when entering the pit, the cooling time in the pit is 86h, and the temperature out of the pit is 87°C;

[0071] (3) For the surface inspection process of continuous casting slabs, visually check whether there are cracks on the surface and corners of each slab. Cracks; if cracks are found by visual inspection or low-magnification samples, peel the billets one by one (single-side peeling ≥ 3mm);

[0072] (4) Conduct surface inspection on the continuous casting slab to be heated, adopt four-stage heating control, and perform preheating, first-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com