Molding sand clearing device for pneumatic cylinder cover inner cavity

A technology for removing device and cylinder head, applied in the field of cylinder head processing and manufacturing, can solve the problems of high product defect rate, noise pollution, and difficulty in falling sand, and achieve the effect of reducing the defective product rate, reducing noise pollution, and ensuring health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

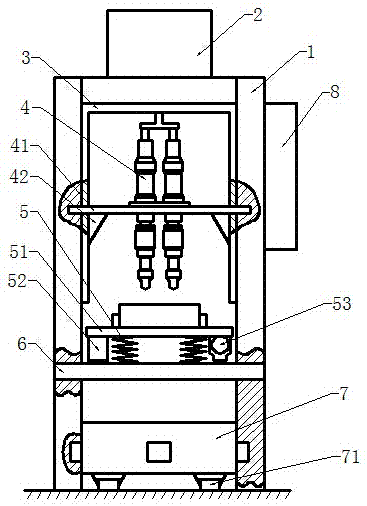

[0013] The reference signs in the drawings of the description include: frame 1, air pump 2, sponge sound-absorbing layer 3, high-pressure air gun 4, mounting plate 41, support rod 42, vibrating spring 5, vibrating plate 51, balance weight 52, vibrating motor 53. Support plate 6, sand collection box 7, rollers, control box 8.

[0014] The embodiment is basically as attached figure 1 Shown: the mold sand removal device for the inner chamber of the pneumatic cylinder head, including a frame 1, a support mechanism, an air pump 2 and a silencer mechanism. The support mechanism includes a support plate 6 and a mounting plate 41, and the support plate 6 is installed on the The bottom of the frame 1, the below of the support plate 6 is provided with a sand collection box 7 that is slidably connected on the frame 1, and the bottom end of the sand collection box 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com